2025 Guide: How to Choose the Right Industrial Diaphragm Valves for Your Needs

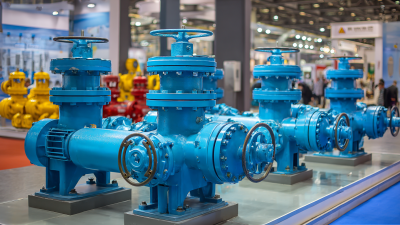

When it comes to optimizing industrial processes, the choice of components plays a crucial role in overall efficiency and reliability. One such component that often goes overlooked is the industrial diaphragm valve. These valves are vital in controlling the flow of various fluids within a range of applications, from chemical processing to water management. As the demand for precise flow control and durability continues to rise, selecting the right industrial diaphragm valves becomes increasingly important for operators striving for excellence in their operations.

In this guide, we will explore the key considerations for choosing the ideal industrial diaphragm valves to meet your specific needs. Factors such as material compatibility, pressure ratings, and the specific operating environment will be analyzed in detail. Understanding these elements not only enhances performance but also extends the lifespan of the valves, ultimately leading to significant cost savings and increased operational reliability. Whether you are a seasoned engineer or new to valve selection, this guide will equip you with the knowledge necessary to make informed decisions that align with your operational goals.

Understanding Industrial Diaphragm Valves: Key Features and Functions

Industrial diaphragm valves are crucial components in numerous applications where precise fluid control is essential. Their design features a flexible membrane that separates the valve body from the internal fluid, making them ideal for handling corrosive substances or slurries. This unique construction minimizes the risk of contamination and provides a reliable seal.

Understanding the key functions of these valves is vital for making an informed selection. They offer advantages such as low maintenance, excellent flow regulation, and adaptability to various pressures and temperatures.

When considering diaphragm valves, pay attention to factors like material compatibility and pressure ratings. Opt for a valve constructed from materials that can withstand the specific chemicals and conditions of your application. Additionally, consider the valve size and actuation method—manual or automated—as these will affect installation and overall operation.

Tips: Always consult with a knowledgeable supplier to discuss your specific requirements. They can offer valuable insights based on your application needs. It's also beneficial to conduct thorough testing or request sample materials before making a final decision, ensuring that the selected valve performs optimally in your system.

Identifying Your Application Needs: Selecting the Right Valve Type

When selecting the right industrial diaphragm valve, it is imperative to first identify your specific application needs. Different industries, such as pharmaceuticals, food and beverage, and chemical processing, often require distinct characteristics from their valves. Considerations encompass the fluid being handled, temperature ranges, pressure specifications, and environmental conditions. For example, a valve with a smooth, non-porous surface might be necessary for sanitary applications to prevent contamination.

**Tips:** Start with a thorough analysis of your system requirements. Assess fluid characteristics, such as whether it is corrosive or abrasive, as this will influence the materials and design needed for durability and performance.

The type of actuation is another vital factor to consider. Manual, pneumatic, or electric actuation options provide various advantages depending on the operational context. For applications requiring frequent valve adjustments, automated actuators may enhance efficiency but could add complexity. Understand how the valve will be operated and which features, such as fail-safety options or remote control capabilities, best suit your operational protocols.

**Tips:** Evaluate how critical it is for your valve to react quickly to changes in flow or pressure as this can inform your choice of actuator. Ensure that the valve can integrate seamlessly with your existing systems to avoid costly modifications later on.

2025 Guide: How to Choose the Right Industrial Diaphragm Valves for Your Needs

| Valve Type |

Application |

Material |

Pressure Rating |

Temperature Range |

Typical Use Cases |

| PTFE Diaphragm Valve |

Chemical Processing |

PTFE |

150 psi |

-20°C to 120°C |

Corrosive Fluids |

| EPDM Diaphragm Valve |

Water Treatment |

EPDM |

200 psi |

0°C to 85°C |

Wastewater Handling |

| Rubber Diaphragm Valve |

Food and Beverage |

Rubber |

100 psi |

-10°C to 90°C |

Food Processing |

| Metal Diaphragm Valve |

High Pressure |

Stainless Steel |

500 psi |

-40°C to 150°C |

Gas and Oil Industries |

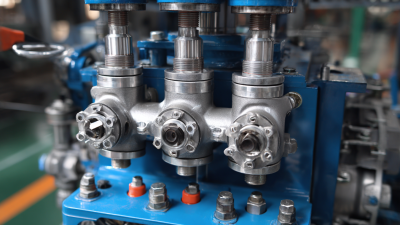

Materials and Construction: Factors Influencing Durability and Performance

When selecting industrial diaphragm valves, the choice of materials and construction plays a crucial role in determining both durability and performance. According to a report by the Industrial Valves Market Analysis, nearly 30% of valve failures in process industries are attributed to inappropriate material selection. This emphasizes the necessity for engineers and procurement teams to understand how different materials interact with various fluids and environmental conditions.

Common materials used in diaphragm valves include PTFE, rubber, and metal alloys, each offering unique advantages depending on the application. For instance, PTFE provides excellent chemical resistance and can maintain functionality at high temperatures, making it ideal for aggressive fluids. Conversely, rubber diaphragms are known for their flexibility and are suitable for less corrosive environments.

The construction of the valve, including the design of the diaphragm and the quality of seals, also significantly influences long-term reliability. A survey conducted by the Valve Manufacturers Association highlighted that 68% of maintenance professionals cite seal integrity as a key factor in the extended lifespan of diaphragm valves.

Ultimately, understanding the interplay between material characteristics and construction quality is essential for optimizing the performance of diaphragm valves in demanding industrial applications. By making informed material choices informed by industry data, facilities can enhance operational efficiency and reduce the frequency of maintenance interventions.

Size and Pressure Ratings: Ensuring Compatibility with System Requirements

When selecting industrial diaphragm valves, understanding size and pressure ratings is critical for ensuring compatibility with your system requirements. According to a recent report by the Global Industrial Valve Market Research, the correct size of a diaphragm valve not only affects the flow rate but also impacts the overall efficiency of the system. Standard dimensions such as 1 inch, 2 inch, and 3 inch have been found to be optimal for various applications, ensuring effective control over fluids while minimizing leaks and pressure loss.

Moreover, pressure ratings are essential for the safe operation of diaphragm valves. The American Society of Mechanical Engineers (ASME) sets comprehensive guidelines on pressure classifications, which can range from Class 150 to Class 2500. Selecting a valve that meets or exceeds the required pressure rating ensures it can withstand the operational demands without failing. For instance, a study published in the Journal of Valve Engineering highlighted that incorrect pressure ratings can lead to catastrophic failures in systems dealing with high-pressure gases or corrosive liquids, underscoring the importance of conforming to industry standards during the selection process. Thus, thorough assessment of both size and pressure ratings not only optimizes valve performance but also enhances system safety and reliability.

Maintenance and Operational Considerations for Long-Term Use

When selecting industrial diaphragm valves, understanding maintenance and operational considerations is crucial for ensuring long-term efficacy and reliability. According to a report by the Fluid Control Institute, improper maintenance can lead to a staggering 30% reduction in valve life, emphasizing the importance of regular inspection and upkeep. Routine maintenance practices, such as checking for leaks, ensuring proper alignment, and replacing worn diaphragms, can significantly enhance performance and prevent costly downtime.

Furthermore, operational factors such as fluid characteristics, pressure fluctuations, and temperature variations play a pivotal role in the lifespan of diaphragm valves. A study by the Valve Manufacturers Association highlights that nearly 40% of valve failures are due to environmental stresses not aligned with the valve's specifications. By understanding these operational parameters and implementing a preventive maintenance schedule, organizations can mitigate risks and extend the lifespan of their diaphragm valves. Investing in proper training on valve operation and maintenance procedures also ensures that personnel are well-equipped to identify potential issues before they escalate into major problems, fostering a more efficient and safe operation.