2025 Top Industrial Diaphragm Valves Guide for Enhanced Performance

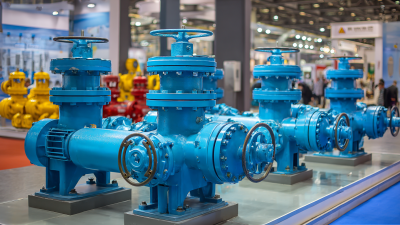

In the ever-evolving landscape of industrial applications, the significance of reliable and efficient control mechanisms cannot be overstated. One such critical component that plays a pivotal role in various processing industries is the industrial diaphragm valve. These valves are designed to manage and regulate flow in systems handling abrasive, corrosive, or viscous materials, offering superior performance and longevity under tough operational conditions. This guide aims to provide an insightful overview of top industrial diaphragm valves anticipated by 2025, focusing on their enhanced performance features that ensure seamless integration into modern industrial processes.

As industries strive for improved efficiency and sustainability, the demand for advanced valve technology continues to grow. Industrial diaphragm valves stand out due to their exceptional sealing capabilities and ease of maintenance, making them an indispensable choice for many applications. By emphasizing innovation and technological advancements, this guide will explore the key aspects of diaphragm valve design and functionality, highlighting trends that are shaping their development. With a focus on performance optimization, this introduction sets the stage for a comprehensive examination of the best options available in the market to suit varying industrial needs, ultimately ensuring that operations run smoothly and efficiently.

Overview of Industrial Diaphragm Valves and Their Functionality

Industrial diaphragm valves are essential components in various sectors, including water treatment, pharmaceuticals, and food processing. These valves utilize a flexible diaphragm to control the flow of fluids, providing reliable sealing and minimal risk of contamination, which is crucial in industries that prioritize hygiene and safety. According to a recent report by the Global Industrial Valve Market, diaphragm valves are anticipated to grow at a CAGR of 6% from 2023 to 2028, highlighting their increasing importance across various industrial applications.

The functionality of diaphragm valves stems from their unique design, which allows them to act not only as a flow control device but also as a safety mechanism. The diaphragm separates the valve opening from the actuator, preventing any direct contact between the fluid and mechanical components. This feature significantly reduces maintenance needs and extends the lifespan of the valves. Additionally, diaphragm valves can perform effectively in high-pressure and abrasive environments, making them suitable for diverse fluid types. Industry studies indicate that diaphragm valves are among the most favored types due to their versatility and performance reliability, positioned within a market that increasingly demands efficiency and sustainability.

Moreover, advancements in materials and design technology have enhanced the operational capabilities of diaphragm valves. Modern alternatives utilize advanced elastomers and corrosion-resistant materials, achieving improved performance in extreme conditions. Research indicates that valves made from these advanced materials can see service life improvements exceeding 30%, reducing replacement costs and downtime for industries reliant on continuous operations. As the industrial landscape evolves, diaphragm valves stand out as a key solution for optimizing processes while meeting stringent performance standards.

2025 Top Industrial Diaphragm Valves Guide for Enhanced Performance

| Valve Type |

Material |

Pressure Rating (PSI) |

Temperature Range (°F) |

Applications |

| Bi-directional Diaphragm Valve |

PVC/EPDM |

150 |

32 to 140 |

Water Treatment, Chemical Processing |

| Sanitary Diaphragm Valve |

Stainless Steel |

250 |

-20 to 275 |

Food and Beverage, Pharmaceuticals |

| Pneumatic Diaphragm Valve |

Polypropylene |

100 |

0 to 120 |

Wastewater Management, HVAC |

| Electric Actuated Diaphragm Valve |

PVDF |

300 |

-40 to 190 |

Chemical Processing, Corrosive Fluids |

Key Features to Consider in 2025 Diaphragm Valve Designs

As we approach 2025, the design of diaphragm valves is evolving to meet the increasing demands of various industries. Key features to consider in diaphragm valve designs include material compatibility, actuation methods, and sealing technologies. According to a recent market report, the global diaphragm valve market is projected to grow at a CAGR of 5.4%, driven by advancements in materials that enhance chemical resistance and longevity, making it crucial for manufacturers to focus on these aspects.

Manufacturers are increasingly incorporating elastomer compounds that not only withstand a wider range of chemicals but also offer better flexibility. Additionally, the integration of smart technology for remote actuation and monitoring is becoming a standard expectation. Industry experts highlight that valves equipped with automated sensors can improve system efficiency and minimize downtime by allowing for real-time monitoring and predictive maintenance.

Tips: When selecting diaphragm valves, ensure that the materials used are compatible with the specific media being controlled. This not only prolongs valve life but also ensures safety and reliability. Furthermore, consider valves that offer modular components for easy upgrades and adaptability in the future, as this can significantly reduce operational costs and increase performance efficiency.

2025 Diaphragm Valves Performance Metrics

Performance Enhancements from Advanced Materials and Technologies

The evolution of diaphragm valves has been significantly influenced by the introduction of advanced materials and technologies, leading to enhanced performance across various industrial applications. Reports indicate that the use of high-performance elastomers and polymers has improved the durability and reliability of these valves, reducing operating costs and downtime. According to a recent industry study, valves made from innovative materials can offer a lifespan improvement of up to 30% compared to traditional options. These enhancements are particularly valuable in sectors like chemical processing, where exposure to harsh substances can accelerate wear and tear.

Incorporating automation technologies and smart systems has also revolutionized the functionality of diaphragm valves. Recent advancements in sensor technology allow for real-time monitoring and predictive maintenance, enabling operators to optimize system performance and avert potential failures. The integration of such technologies can lead to a 20% increase in efficiency, as revealed by a study from the Industrial Automation Association.

Tips: When selecting diaphragm valves, consider the specific requirements of your application, including media type and pressure ranges. Additionally, evaluate the compatibility of materials to ensure longevity and reduce maintenance needs. Balancing performance enhancements with cost considerations can significantly impact your operation's efficiency and productivity.

Maintenance Best Practices for Long-lasting Valve Efficiency

Maintenance plays a crucial role in ensuring the efficient performance of diaphragm valves, which are essential in various industrial applications. Regular inspection and maintenance routines should be established to monitor valve conditions. Key aspects of maintenance include checking for signs of wear and tear, such as leaks or abnormal noises, which can indicate the need for repairs or replacement. It is also important to maintain cleanliness in valve areas to prevent the accumulation of debris that can hinder performance or cause premature failures.

Additionally, lubrication is vital to prolonging the life of diaphragm valves. Appropriate lubricants should be applied to moving components to minimize friction and wear. It is essential to consult the valve's specifications to identify suitable lubricants that will not compromise the materials used in the valve construction. Operators should also follow manufacturer guidelines concerning maintenance intervals, ensuring that any preventive measures or replacements are conducted in a timely manner. By adhering to these best practices, facilities can enhance the performance and reliability of diaphragm valves, ultimately reducing downtime and maintenance costs.

Trends in Industrial Applications of Diaphragm Valves by 2025

As we look toward 2025, the industrial applications of diaphragm valves are evolving rapidly, driven by advancements in technology and increasing demands for efficiency. Industries such as pharmaceuticals, food and beverage, and water treatment are increasingly adopting diaphragm valves due to their reliability and versatility. These valves excel in applications that require strict hygiene standards and precise control over fluid flow, making them a preferred choice in sensitive environments.

Tips: When selecting diaphragm valves for industrial applications, consider the material compatibility with the fluids being handled. This is crucial in ensuring valve longevity and performance under varying temperatures and pressure conditions. Additionally, integrating smart technologies, such as IoT-enabled monitoring systems, can further enhance operational efficiency by providing real-time data and predictive maintenance insights.

The trend toward automation and digitalization in industrial processes is also driving the development of diaphragm valves. As manufacturers aim to optimize production lines and reduce downtime, the demand for valves that can seamlessly integrate with automated systems will continue to grow. This shift not only improves efficiency but also enhances safety by minimizing manual intervention in hazardous environments.