2026 Top Valve Valves for Industrial Applications What to Know?

In the industrial landscape, selecting the right valve valves is crucial. These components control fluid flow and pressure. The choice impacts system efficiency and reliability. Various types of valve valves serve different purposes. There are ball valves, gate valves, and butterfly valves, to name a few.

Understanding the specific needs of your application is vital. A mismatch can lead to operational issues. For example, a valve not rated for high pressure can fail. Such failures can disrupt production and increase costs. Additionally, maintenance needs vary among different valve valves. Some require frequent checks, while others are low-maintenance.

As industries evolve, so do valve valves. Innovations emerge to enhance functionality and performance. However, not every new technology suits all applications. Engineers must carefully evaluate options. Balancing cost, efficiency, and durability is often challenging. Reflecting on past choices can lead to better decisions in the future.

Overview of Valve Types in Industrial Applications

In industrial applications, valves play a crucial role in controlling fluid flow. There are several types of valves used in various industries, each designed for specific functions.

Ball valves offer a reliable shut-off but can face issues with sealing over time. Gate valves are great for on/off control but not ideal in throttling scenarios. Understanding these nuances is essential for optimal operation.

Butterfly valves are lightweight and cost-effective, making them popular for large-diameter pipes. However, they may not provide a tight seal under all conditions.

Globe valves excel in flow regulation but require more space and can be less efficient in high-pressure environments. It's important to assess the specific needs of each application to select the right valve type.

Proper installation and maintenance are key factors in maximizing valve performance. Many professionals overlook this aspect, leading to premature failure. Regular inspections can help catch issues before they escalate. The complexity of fluid dynamics often requires thoughtful consideration when choosing and managing valves. Choosing the right type can seem daunting but involves a mix of technical knowledge and practical experience.

Key Features to Consider When Selecting Valves

When selecting valves for industrial applications, several key features play a crucial role.

Consider the valve type and its application.

Gate valves, ball valves, and butterfly valves each serve different functions. Wrong selections can lead to inefficiencies.

Material compatibility is another vital factor.

Investigate the materials used in the valve construction. Ensure they withstand the pressures and temperatures of your system.

The size of the valve matters, too. An improperly sized valve can restrict flow or cause excess wear.

Take precise measurements.

Think about the actuation method. Manual, electric, and pneumatic actuators can vary in response time and control.

Each method has its pros and cons. It’s essential to reflect on operational needs and maintenance requirements, too.

Don’t overlook the pressure ratings.

Valves must operate safely within the specified limits. A mismatch can lead to failures.

Lastly, consider reliability. A valve’s longevity in harsh conditions is key.

Regular assessments can help identify wear and tear before it becomes critical.

In the end, balancing these factors ensures optimal performance and safety in your industrial applications.

Top Manufacturers of Industrial Valves in 2026

In 2026, the landscape of industrial valves continues to evolve. Numerous manufacturers are stepping up their game. Their innovations drive efficiency in various applications. These companies focus on sustainability and performance. Moreover, they also prioritize safety standards across the board.

Choosing the right manufacturer is crucial. Many companies offer different valve types, including globe, gate, and ball valves. Each design serves specific needs. For instance, some excel in high-pressure environments, while others cater to low-flow systems. It's important to assess which features are necessary for your application.

In addition, the industry faces challenges. Supply chain issues can cause delays. Manufacturers may struggle with raw material shortages. These factors could impact production timelines and costs. Companies should remain flexible and prepared for these uncertainties. Ongoing innovation is key for staying competitive. It is essential to keep an eye on the latest technologies and trends.

Innovative Technologies Shaping the Future of Valves

Innovative technologies are paving the way for the future of valves in industrial applications. One notable trend is the rise of smart valves. These devices use sensors to monitor performance and adjust operations in real-time. This can enhance efficiency and reduce energy consumption. Imagine a valve that automatically responds to changes in pressure or temperature. It’s a significant leap forward.

Another exciting development is the use of advanced materials. Many industries now utilize lightweight, corrosion-resistant materials for valve construction. These materials can withstand harsh environments. However, there’s a downside. Some of these materials might be more expensive initially, making them a challenging choice for some companies. Balancing cost and performance remains a crucial discussion point.

Furthermore, data analytics plays a vital role. Leveraging big data can lead to predictive maintenance. Tracking valve performance over time helps in spotting potential issues before they escalate. However, not every company has the necessary infrastructure in place to take full advantage. This raises questions about accessibility and adaptation. A lot remains to be explored in this rapidly evolving field.

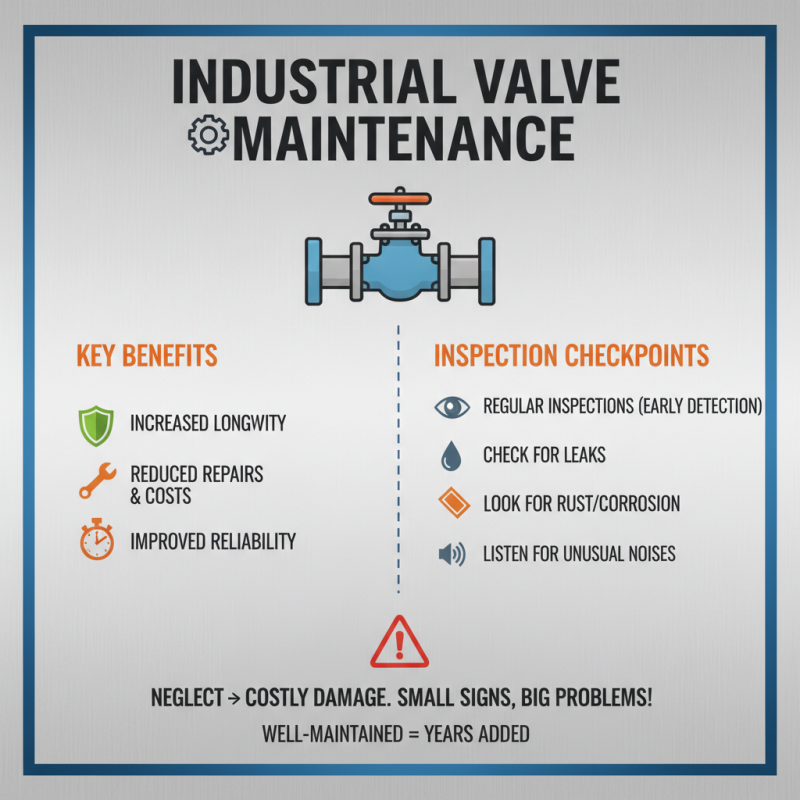

Maintenance Best Practices for Industrial Valve Longevity

Maintaining industrial valves is crucial for their longevity. Regular inspections help identify wear and damage early. Operators should check for leaks, rust, and unusual noises. These signs often indicate a bigger issue. A well-maintained valve can last years longer than one that is neglected. It’s easy to overlook small signs, but that can lead to costly repairs.

Lubrication is also vital. Applying the right lubricant prevents friction and wear. However, too much lubricant can attract dust and dirt. Finding the right balance is a challenge for many. Cleaning valves should be part of the routine. Dirt buildup can jam moving parts, leading to breakdowns. Simple cleaning techniques can make a significant difference in performance.

Training staff is another essential aspect. Proper training ensures everyone understands maintenance procedures. Lack of knowledge can result in improper handling. Documenting issues and repairs can help track long-term performance. Reflection on past mistakes is necessary for improvement. Each valve presents unique challenges; learning from these is key.