Top 5 Best Actuator Valves for Enhanced Control in Fluid Systems?

Actuator valves play a crucial role in fluid systems. They help control flow, pressure, and temperature efficiently. Choosing the best actuator valve can enhance system performance and reliability. Various types of actuator valves are available on the market. Each type has its unique features and applications.

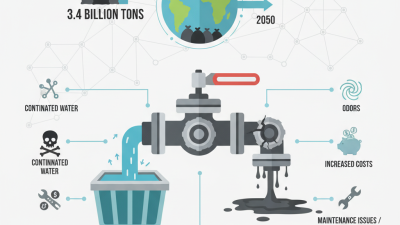

In this discussion, we will explore the top five actuator valves. These valves effectively manage fluid dynamics. A quality actuator valve can prevent leaks and reduce energy consumption. However, not all actuator valves are created equal. Some may not withstand harsh conditions, leading to maintenance challenges. Evaluating them carefully is essential.

Fluid systems are complex, and the right actuator valve can make a difference. Investing time in selecting the best option pays off in the long run. It improves system efficiency and reduces operational costs. But there are always uncertainties in performance. Understanding their specifications and limitations is crucial for better outcomes. The right choice can enhance control, while the wrong one may lead to frustration.

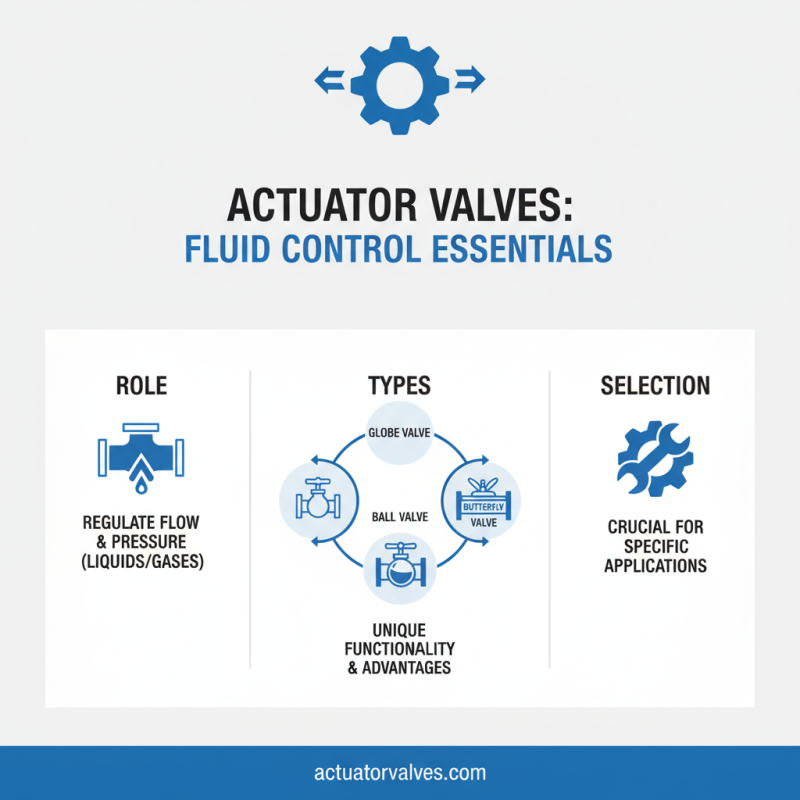

Types of Actuator Valves and Their Functions in Fluid Control

Actuator valves play a crucial role in fluid control systems. They regulate the flow and pressure of liquids and gases. Understanding the types of actuator valves is essential for selecting the right one for specific applications. There are several types available, including globe, ball, and butterfly valves. Each of these valves has its unique functionality and advantages.

Globe valves provide precise flow control. They allow for throttling, which is useful in managing fluid rates. Ball valves are known for their quick shut-off capability. They can be fully opened or closed with a quarter turn. Butterfly valves, on the other hand, are compact and lightweight. They are typically used for larger volumes of fluid.

However, selecting the right actuator valve can be challenging. Factors such as fluid type, pressure, and temperature must be considered. Sometimes, people overlook these specifics and may face performance issues. The ideal valve for one scenario may not work as effectively in another. Reflecting on these details before purchasing is crucial for optimal performance.

Key Features to Consider When Choosing Actuator Valves

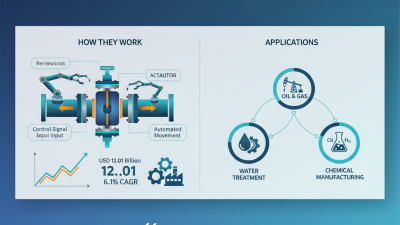

Choosing the right actuator valve is crucial for fluid systems. There are key features that can significantly impact performance. One important factor is the type of actuator. Electric, pneumatic, and hydraulic actuators each have unique benefits. According to a 2022 market analysis, electric actuators demonstrate a 30% energy efficiency improvement over pneumatic models. This efficiency can lead to lower operating costs.

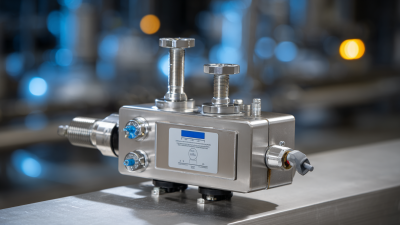

Another critical aspect to consider is the material of the valve. Corrosion resistance is vital for longevity. For instance, stainless steel valves can withstand harsher environments compared to plastic ones. A report from 2023 indicates that using high-quality materials can extend the lifespan of valves by up to 50%. Some applications, however, may require a balance between cost and durability.

Finally, precision in control matters. The responsiveness of the valve can vary. A study published in the Journal of Fluid Dynamics found that well-designed actuator valves can offer up to 98% control accuracy in regulated fluid flow. Regrettably, not all products on the market meet these standards. It's essential to carefully evaluate potential choices to ensure optimal performance in your fluid system.

Top 5 Recommended Actuator Valves for Various Applications

In fluid systems, actuator valves play a crucial role in controlling flow and pressure. Different applications require specific solutions. Choose wisely to enhance efficiency. Studies show that selecting the right actuator valve can improve system performance by up to 30%.

For industrial automation, consider electric actuator valves. They offer precise control and can handle various fluid types. Pneumatic actuator valves are suitable for environments requiring fast response times. These valves excel in high-speed applications, often reducing cycle times significantly. Hydraulic options dominate in heavy-duty scenarios due to their high force capabilities.

Tips: Regular maintenance ensures longevity. Inspect valves for wear and tear periodically. Also, consider upgrading to smart actuators. These can provide real-time data, improving decision-making in operations.

Each valve type comes with trade-offs. Electric valves can be limited by power availability. Pneumatic valves might require compressed air, which can add cost. Assess your system’s needs carefully to make informed choices. It’s essential to understand both strengths and weaknesses. Quality matters here.

Benefits of Using Actuator Valves in Fluid Systems

Actuator valves play a crucial role in fluid systems. They offer precise control over fluid flow. This enhanced control leads to more efficient operations. Engineers often prefer them for automation. Stopping or starting fluid flow becomes easier. With accurate positioning, energy consumption can decrease, promoting sustainability.

Using actuator valves also reduces manual labor. Workers spend less time adjusting valves manually. This shift not only saves time but also minimizes human error. However, some challenges arise. Maintenance can be complex. Occasionally, sensors may fail, disrupting operations. Regular checks are essential to ensure reliability.

In fluid systems, actuator valves improve responsiveness. They adapt quickly to changes in system conditions. This feature prevents pressure build-up or flow disruptions. Yet, improper installation can lead to issues. Ensuring that valves are correctly integrated is vital. Awareness of these challenges can lead to better decisions in fluid management.

Maintenance Tips for Ensuring Optimal Performance of Actuator Valves

Actuator valves play a crucial role in fluid systems. Their performance directly influencers efficiency and operation costs. Regular maintenance is vital to ensure optimal functioning. According to industry reports, poorly maintained valves can lead to energy losses of up to 30%. This statistic highlights the importance of proactive upkeep.

Inspection of actuator valves should be routine. Check for leaks, unusual noises, or performance drops. Lubrication is key, yet many operators overlook it. Insufficient lubrication can cause excess wear. A study indicated that 25% of valve failures were due to inadequate maintenance practices. This is concerning and emphasizes the need for diligence.

Training staff on maintenance best practices is essential. Continuous monitoring can catch issues early. Regular data analysis allows teams to identify trends and anticipate failures. Operators must prioritize these efforts for long-term efficiency. Ensuring all staff members understand the importance of these tasks can significantly enhance system reliability.

Top 5 Best Actuator Valves for Enhanced Control in Fluid Systems

| Valve Type |

Actuation Mechanism |

Flow Control Range |

Operating Pressure |

Maintenance Frequency |

| Ball Valve |

Electric |

1/4" to 4" |

Up to 150 psi |

Annual |

| Globe Valve |

Pneumatic |

1" to 12" |

Up to 300 psi |

Semi-annual |

| Butterfly Valve |

Electric |

2" to 60" |

Up to 150 psi |

Annual |

| Check Valve |

None (gravity) |

1" to 36" |

Up to 200 psi |

Every two years |

| Solenoid Valve |

Electromagnetic |

1/8" to 3" |

Up to 150 psi |

Monthly |