Top 5 Best Pinch Valves for Slurry Applications?

In the world of industrial processes, pinch valves for slurry applications play a crucial role. These valves are essential for controlling the flow of abrasive slurries in various sectors. As expert John Roberts states, "The efficiency of pinch valves for slurry can significantly enhance process reliability."

Pinch valves are designed to handle challenging materials with precision. They provide a simple yet effective method of managing flow without complex mechanisms. However, selecting the right valve can be difficult. There are many options, and each comes with unique features and capabilities. Not every pinch valve suits every application perfectly.

It is vital to consider specific needs, such as the type of slurry and operating conditions. This reflective approach will guide users toward the best choices available. Sometimes, the best option may not be the most popular one. Each application requires careful evaluation to ensure optimal performance. Thus, understanding the nuances of pinch valves for slurry becomes essential.

Top Considerations for Selecting Pinch Valves for Slurry Handling

When selecting pinch valves for slurry applications, several considerations come into play. First, the nature of the slurry is crucial. This includes its viscosity, solid content, and even temperature. Data from industry reports indicate that slurries with higher solid contents can cause wear and tear on valve components. Choosing materials that withstand erosive particles is vital. Many operators overlook the importance of compatibility, which can lead to failures.

Next, the valve size and pressure ratings must match the system requirements. For example, a common error is underestimating the pressure drops that slurries can create. It's essential to analyze flow characteristics and pressure conditions. A report from a leading engineering institute noted that improper sizing could decrease overall efficiency by up to 25%. Operators might fail to account for installation angles and space constraints, which could affect maintenance access.

Finally, ease of maintenance cannot be sidelined. Some pinch valves require complex disassembly for cleaning or replacement. A user survey revealed that over 40% of maintenance downtime results from difficult valve access. Treating maintenance as an afterthought could lead to costly delays. The design and construction should support quick access to keep operations running efficiently.

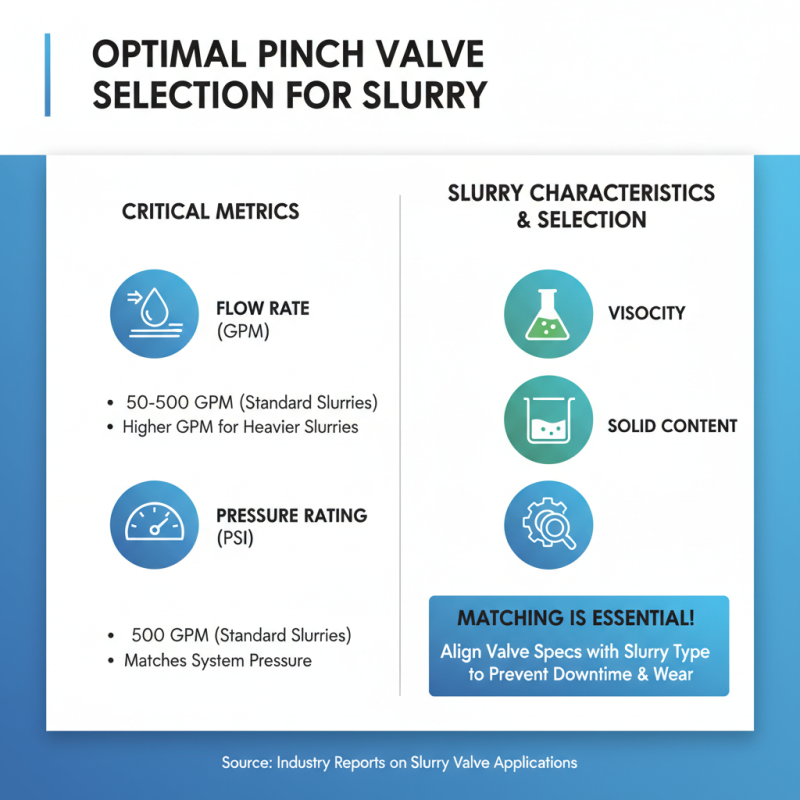

Performance Metrics: Flow Rate and Pressure Ratings in Slurry Valve Applications

When selecting pinch valves for slurry applications, flow rate and pressure ratings are critical metrics. Industry reports indicate that optimal flow rates vary significantly based on the slurry's viscosity and solid content. In many cases, a flow rate between 50 to 500 gallons per minute (GPM) is deemed effective for handling standard slurries. However, some heavier slurries may require even higher capacities. Matching the valve’s specifications with the specific slurry characteristics is essential but often overlooked.

Pressure ratings are equally vital in slurry applications. Many pinch valves can withstand pressures ranging from 10 to 100 psi. However, for abrasive slurries, the internal design and material matter. A miscalculation in pressure ratings can lead to valve failure. Reports show that 15% of failures in slurry handling are linked to incorrect pressure settings. This emphasizes the need for precision and a comprehensive understanding of the application.

Additionally, installation practices can significantly affect performance. Many users do not consider the impact of pipeline layout and valve positioning. Poor alignment can create excessive stress on the valve, impacting its lifespan. Continuous monitoring and regular maintenance are often neglected. These factors cumulatively influence the efficiency and effectiveness of pinch valves in slurry transport systems.

Maintenance and Longevity: Key Factors in Pinch Valve Durability

Pinch valves are essential in slurry applications. Their design makes them suitable for challenging materials. However, maintenance plays a critical role in their longevity. According to industry reports, improper maintenance can reduce a pinch valve's lifespan by up to 40%. Regular inspections are necessary to identify wear and tear.

Subpar materials can also impact durability. Many valves use rubber sleeves that degrade over time. Dust and abrasive materials can worsen this wear. Data shows that valves exposed to harsh conditions require more frequent replacements, increasing operational costs. Operators must choose durable materials and implement a routine maintenance schedule.

Vibration and pressure changes can lead to unexpected failures. An estimated 25% of pinch valve failures result from these factors. Maintaining optimal conditions minimizes stress on the valve. Insufficient attention to these details can have lasting impacts, leading to higher maintenance costs and downtime. A proactive approach is vital for maximizing a pinch valve's operational life.

Top 5 Best Pinch Valves for Slurry Applications

| Valve Model |

Size (inches) |

Pressure Rating (psi) |

Material |

Max Temperature (°F) |

Longevity Rating (Years) |

| Model A |

2 |

150 |

Rubber |

180 |

10 |

| Model B |

3 |

200 |

Polyurethane |

200 |

12 |

| Model C |

4 |

100 |

EPDM |

150 |

8 |

| Model D |

5 |

250 |

Silicone |

220 |

15 |

| Model E |

6 |

300 |

NBR |

180 |

20 |

Industry Standards and Certifications for Slurry Pinch Valve Selection

When selecting pinch valves for slurry applications, industry standards play a crucial role. Understanding material compatibility is essential. Abrasive materials in slurries can degrade valve components quickly. Using valves made from robust materials is key to enhance durability. Certifications can assure users about the quality. Look for valves that meet ISO and ASTM standards. These certifications ensure consistent quality and performance.

Another important aspect is the pressure ratings of the valves. Pinch valves must withstand varying pressures in slurry applications. Not all valves are created equal. Some may guarantee operation only under specific conditions. Testing in real-world scenarios helps confirm performance under stress. Reliable manufacturers often provide test data. This transparency helps in selecting the right valve.

Regular maintenance of pinch valves is often overlooked. Proper maintenance schedules can prolong the life of these valves. It's a simple task yet can be incredibly effective. In contrast, neglecting this can lead to unexpected failures. It’s crucial to reflect on this for long-term efficiency. The importance of adherence to industry standards cannot be overstated. They are not merely boxes to check. They are essential guides to achieving effective slurry handling solutions.