Best Straight Valves for Optimal Performance and Efficiency?

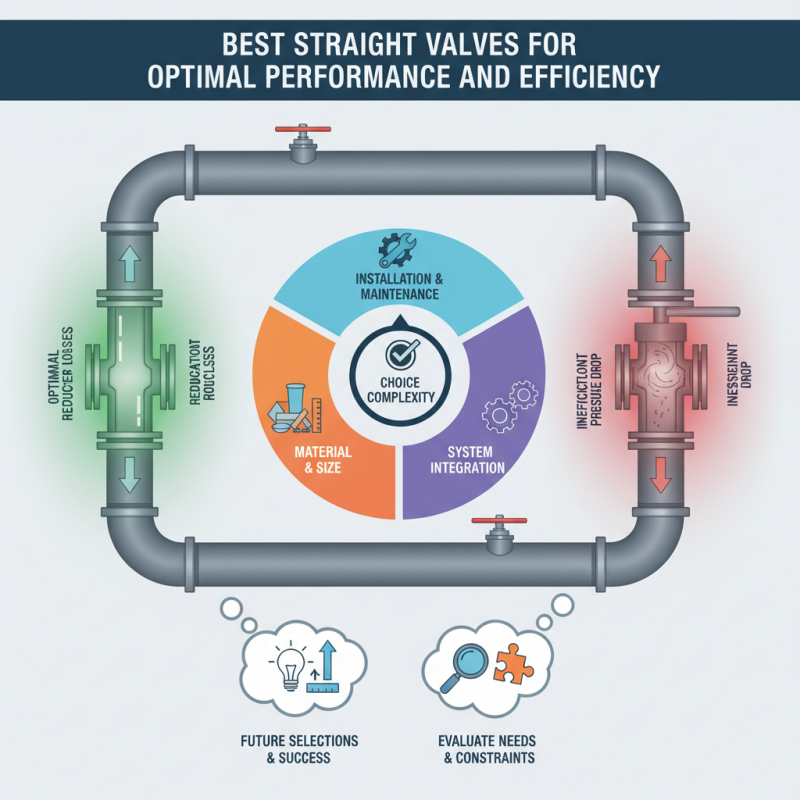

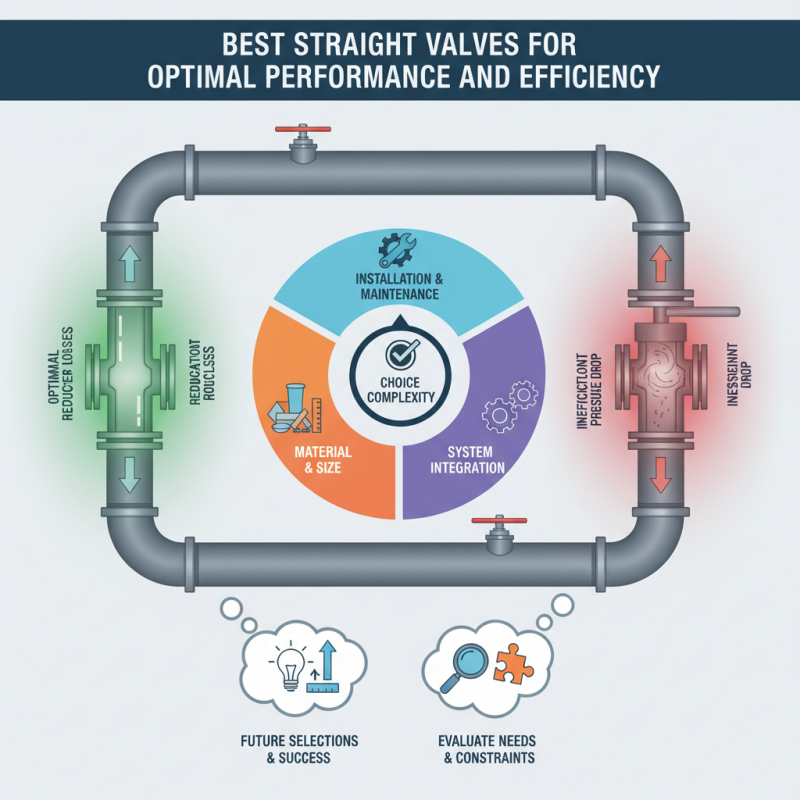

In industrial applications, straight valves play a crucial role in ensuring optimal performance and efficiency. These components are vital for fluid flow control in pipelines, helping to maintain pressure and reduce losses. Selecting the right straight valves can significantly impact system performance, yet the market offers numerous options, making choices complex.

While many focus on features like material and size, it’s also important to consider installation and maintenance. Sometimes, a seemingly perfect valve might not fit well with existing systems. Choosing a straight valve requires careful evaluation of specific needs and constraints. This juncture of performance and efficiency often leaves users pondering if they made the right choice.

Reflecting on what works and what doesn’t can help improve future selections. Efficiency isn’t just about the valve type but how well it integrates with the entire system. Understanding the nuances of straight valves can lead to better decision-making and increased operational success.

Understanding Straight Valves: Types and Applications

Straight valves play a crucial role in various industries. These valves allow fluid to flow in one direction while preventing backflow. Common types include gate valves, ball valves, and globe valves. Each type serves specific applications and offers unique benefits. Gate valves are suitable for on/off conditions, while ball valves provide quick shut-off capabilities.

When selecting a straight valve, performance and efficiency are key considerations. The valve size must match the pipe diameter to minimize turbulence. However, installation can be tricky. A poorly installed valve leads to leaks and increased maintenance costs. Understanding the operating pressure and medium type also affects performance.

In addition to mechanical properties, materials matter. Stainless steel, PVC, and brass are popular choices. Each material has its pros and cons depending on the application environment. Regrettably, many overlook these details. Choosing the wrong type can result in reduced efficiency or even failure. Thus, careful planning and review of options are essential for optimal performance.

Performance Comparison of Different Types of Straight Valves

Key Features of High-Performance Straight Valves

When selecting straight valves, it's crucial to focus on specific features that enhance performance and efficiency. High-performance straight valves should be durable and reliable. Wear resistance is a crucial factor. A report from the American Society of Mechanical Engineers indicates that over 75% of valve failures result from wear and corrosion. Choosing materials like stainless steel or robust polymers can mitigate wear issues significantly.

Flow capacity is another vital feature. Valves with a high Cv rating allow for better flow rates while minimizing pressure drops. This efficiency is essential in applications that demand constant pressure. Research shows that optimizing flow characteristics can lead to energy savings of around 20% in many systems. However, not all valves achieve this effectively, often leading to suboptimal performance in systems that require precise control.

Moreover, compatibility with various media plays a key role. High-performance valves must withstand different temperatures and pressures without compromising functionality. Regular maintenance is also paramount. Neglecting routine checks can lead to malfunctions, reflecting the need for proactive approaches. Although some designs boast long service lives, many fall short under real-world conditions, prompting the need for continuous evaluation and adjustment. Striking the right balance between features can lead to significant gains but requires careful consideration of each element in a system.

Material Selection for Enhanced Valve Efficiency

When selecting materials for straight valves, efficiency is key. The right material can enhance performance, reduce wear, and increase longevity. Common choices include stainless steel, brass, and plastics. Each material serves distinct purposes in various environments. Stainless steel offers corrosion resistance but can be costlier. Brass provides strength and can resist high pressures. Plastics, while lightweight, may not handle extreme temperatures well.

Moreover, it’s essential to consider the specific application. For high-pressure systems, durability is crucial. For chemical processing, compatibility with fluids is vital. However, misunderstandings can occur. Some may overlook the effects of temperature on materials. A valve that works well at room temperature may fail under heat. This misjudgment can lead to leaks and costly repairs.

In addition, installation and maintenance practices impact efficiency. Improper alignment can cause unnecessary stress on the valve. Regular inspections are often neglected, leading to performance issues. Mistakes in material choice or care can hinder optimal function. Reflecting on these factors can lead to smarter, more effective valve selections. Choosing the right material requires careful consideration. The goal should always be sustained performance and efficiency.

Evaluating Valve Efficiency: Metrics and Testing Methods

When evaluating valve efficiency, various metrics can offer crucial insights. Pressure drop is a key indicator. It reflects how well a valve maintains flow under pressure. A minimal pressure drop typically suggests better efficiency. Flow coefficient (Cv) is another essential measurement. It indicates the valve's capacity to pass fluid. Higher Cv values generally mean improved performance. Each application might require different efficiency metrics.

Tips: Regularly inspect the valves for wear. Minor issues can lead to significant inefficiencies. Ensure alignment is correct. Misalignments can increase pressure drops, reducing overall efficiency.

Testing methods often include flow tests and computer simulations. Real-world data is invaluable. Simulated tests can predict performance under varied conditions. The choice of testing method depends on available resources. It's also important to factor in installation variables. Some setups might mask true valve performance.

Consider variables like temperature and fluid viscosity. They can drastically change efficiency outcomes. As you assess performance, think about maintenance practices too. They're just as crucial as initial testing. A valve can perform well but age poorly without care.