2026 Best Valve Power Solutions for Optimal Performance and Efficiency?

As industries evolve, the importance of valve power solutions grows ever more significant. In 2026, optimizing performance and efficiency remains crucial. According to the latest report by the Valve Institute, energy-efficient systems can reduce operational costs by up to 20%. This is a wake-up call for companies seeking to enhance their operations.

Industry expert Dr. Emily Hargrove emphasizes this point: “The effectiveness of valve power directly influences overall productivity.” Companies must innovate to stay competitive. However, many struggle with outdated systems and technologies. Selecting the right valve power solution is not just an option; it is a necessity.

A shift toward smart and efficient valve solutions is visible. Yet, some organizations still cling to traditional methods. This resistance can stifle innovation and efficiency. The need for performance improvements in valve power systems is more pressing than ever. Moving forward, the industry must address these challenges to harness the full potential of valve technologies.

Overview of Valve Power Solutions and Their Importance

Valve power solutions play a crucial role in various industries. They control the flow of liquids and gases with precision. This control is vital for maintaining safety and efficiency. Without effective valve power systems, operations can falter. Inadequate power solutions often lead to inefficiencies. This can result in increased operational costs and downtime.

Choosing the right valve power solution is not always straightforward. Many factors come into play. Energy consumption is key. High energy costs can diminish profitability. Additionally, improper sizing and selection of valve actuators are common mistakes. These errors can affect system performance, leading to unpredictable results. Regular assessments are essential. They help identify potential improvements and avoid future issues.

Moreover, organizations sometimes overlook maintenance. A lack of proper upkeep can result in performance degradation. Reacting too late is a common pitfall. Awareness and timely interventions are vital for optimal operation. Investing in the right technology and maintenance practices is critical. It ensures that valve systems perform efficiently and reliably over time.

Key Factors Influencing Valve Performance and Efficiency

In the quest for optimal valve performance, several factors come into play. Understanding these factors is key for enhancing efficiency. The selection of materials is crucial. Materials that resist corrosion and wear contribute to longevity. Additionally, the design of the valve affects its ability to handle pressure and flow rate effectively.

Tips: Consider your environment. Does your valve face extreme temperatures or corrosive substances? Choose materials wisely.

Another major factor is the installation process. A poorly installed valve can lead to leaks and inefficiency. Ensure that the fittings are tight and that the valves are aligned correctly. Regular maintenance is also vital. Check for signs of wear and proactively replace components when necessary.

Tips: Schedule routine maintenance checks. This can prevent unexpected failures.

Lastly, system compatibility should not be overlooked. A valve must work well with other system components. Misaligned systems can lead to poor performance. Collaborate closely with engineers to ensure all parts harmonize.

Tips: Engage in team discussions about system integration. Awareness is key to finding solutions early.

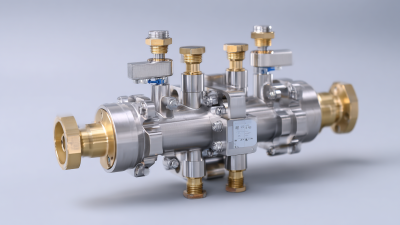

Top Valve Technologies for Enhanced Power Solutions in 2026

In 2026, valve technologies are evolving rapidly. Enhanced power solutions rely on these advancements. A recent industry report shows that smart valves can improve efficiency by 25%. These valves adapt automatically to system conditions, reducing energy waste. Users appreciate this technology for its adaptability and performance.

Pressure control is crucial in optimizing power solutions. Data reveals that advanced pressure-regulating valves contribute to energy savings of up to 30%. They ensure systems operate under optimal conditions. Yet, some users find the initial investment daunting. The long-term benefits often outweigh these costs, but the hesitation remains a barrier.

Another notable trend is the use of durable materials. High-performance alloys ensure valves withstand harsh environments. Reports indicate that this can extend valve life by over 50%. However, the reliance on advanced materials raises questions about cost-effectiveness. When balancing performance with budget constraints, many find it challenging to decide. As the technology progresses, reflections on such choices will be necessary for future optimization.

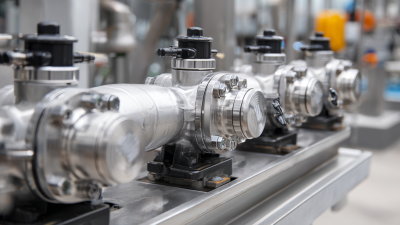

Comparative Analysis of Leading Valve Brands and Models

In 2026, the valve power solutions market is evolving rapidly. A comparative analysis reveals key insights into the performance and efficiency of various valve models. Industry studies indicate that top-performing valves can enhance system efficiency by up to 30%. This improvement often results in significant cost savings and energy efficiency.

A notable aspect of modern valves is their technological integration. Many leading models utilize smart sensors for real-time monitoring. This feature allows for quick identification of issues, potentially reducing downtime by 20%. However, not all valves deliver on these promises. A recent report highlighted that around 15% of valve failures stem from ineffective designs.

Reflections on durability are essential. While many brands promote robust construction, the reality often tells a different story. Some valves show wear and tear much sooner than expected. Choosing a valve based solely on brand reputation can lead to disappointment. An informed decision requires careful evaluation of performance data and durability reports. This is crucial for achieving optimal results in any application.

2026 Best Valve Power Solutions for Optimal Performance and Efficiency

This chart represents a comparative analysis of various valve performance metrics for optimal efficiency and functionality. Each metric is rated on a scale of 0 to 100, highlighting the key attributes that determine effective valve solutions.

Future Trends in Valve Power Solutions and Their Industry Impact

The future of valve power solutions is rapidly evolving.

Advancements in technology will play a crucial role. Efficient power usage and automation are becoming essential.

Industries are increasingly adopting smarter valves to reduce energy costs. Enhanced data analytics will drive better decision-making.

Tip: Regularly evaluate your current valve technologies. Look for upgrades that enhance efficiency and performance.

Investing in the right solutions can yield significant long-term benefits.

Trends indicate a shift toward eco-friendly options. Sustainability is a priority for many companies.

This pressure is pushing manufacturers to innovate. However, not all solutions will suit every application.

Businesses must consider their specific needs carefully.

Tip: Conduct thorough research before making an upgrade.

Understand the implications of new technologies. Not every trend will lead to improved performance.

Review case studies and seek expert opinions when necessary.