Unlocking Efficiency: How Body Valves Transform Fluid Control Systems

In the realm of fluid control systems, the role of body valves is pivotal in enhancing overall efficiency. According to a recent report by MarketsandMarkets, the global valve market is projected to reach USD 102.5 billion by 2026, primarily driven by the increasing demand for effective fluid control in various industries such as oil and gas, water and wastewater management, and power generation. Body valves serve as critical components in these systems, enabling precise regulation of flow and pressure, thereby optimizing operations.

These advancements in valve technology not only contribute to energy savings but also facilitate compliance with stringent environmental regulations. As industries continue to prioritize automation and efficiency, understanding the transformative impact of body valves is essential for engineers and decision-makers alike in the quest for improved process performance.

The Essential Role of Body Valves in Fluid Control Systems

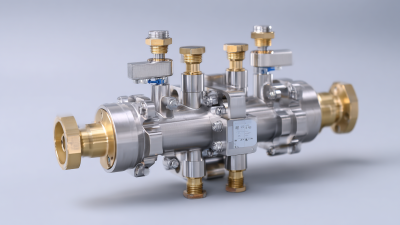

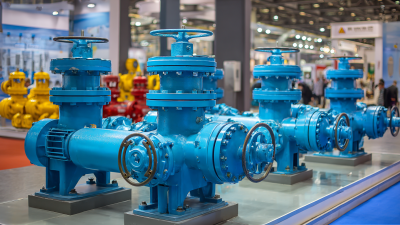

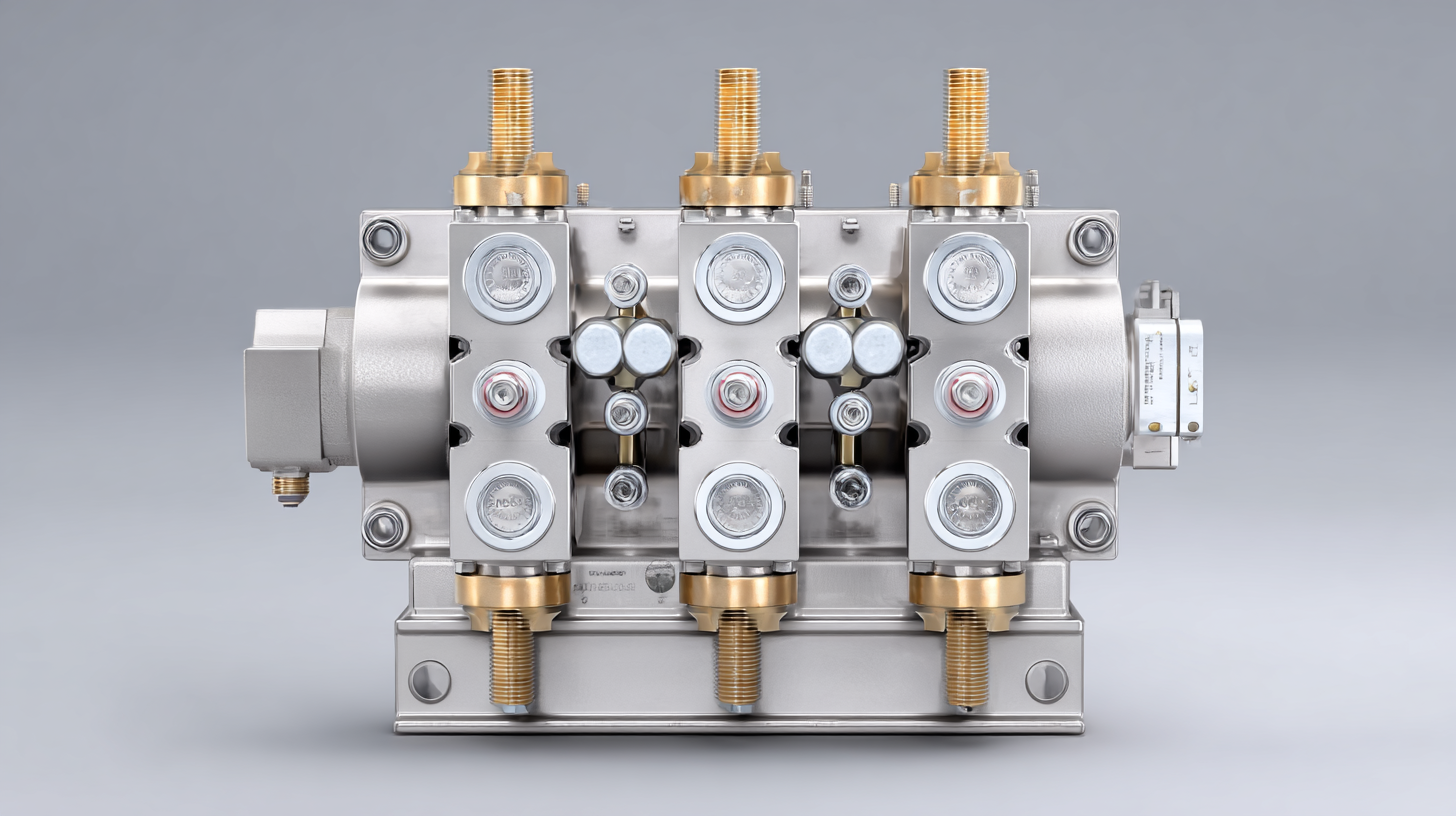

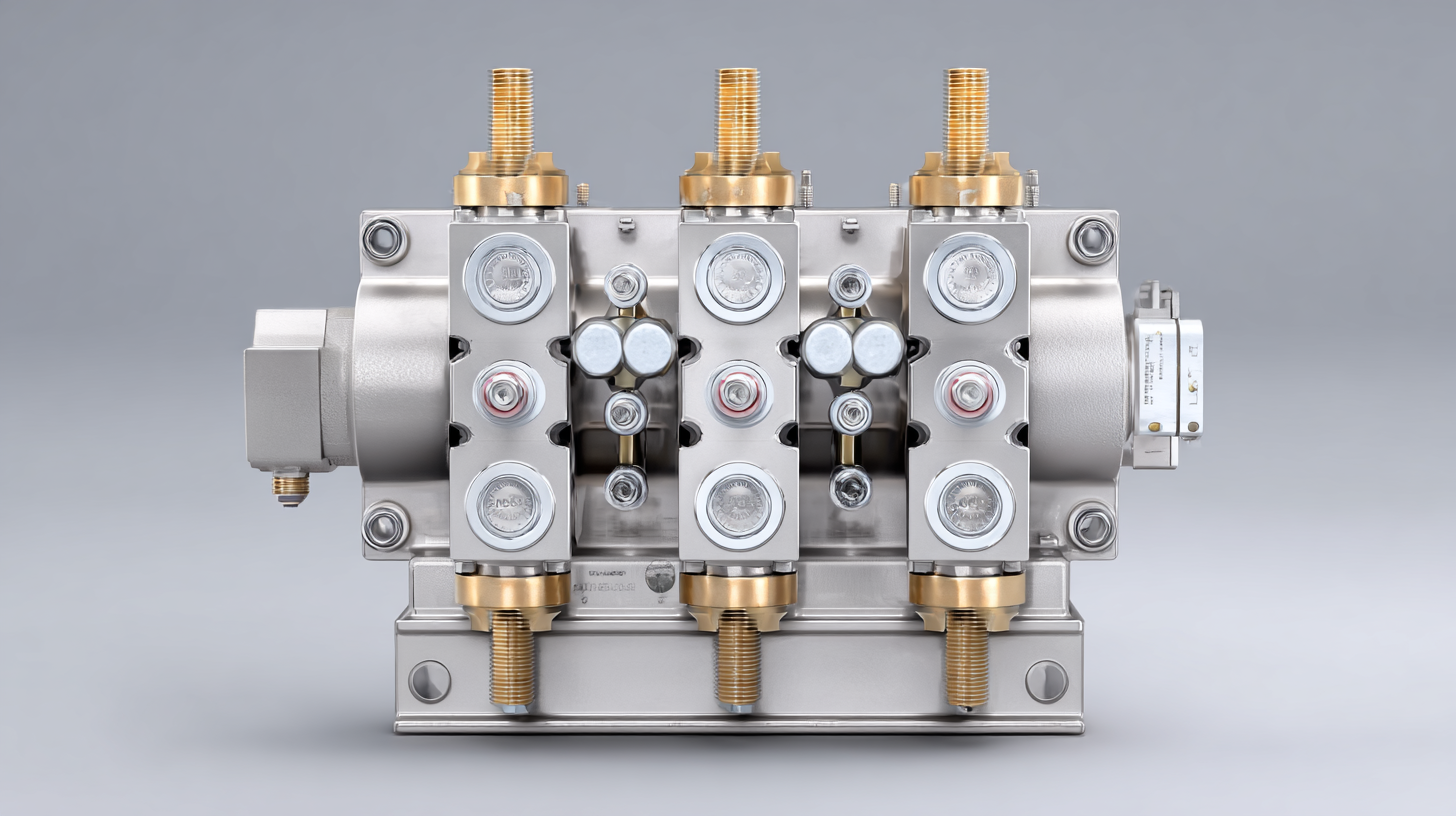

Body valves play a crucial role in fluid control systems, serving as the gatekeepers of flow management across various industries. According to a report by Research and Markets, the global market for fluid control systems is projected to reach $10 billion by 2024, highlighting the increasing demand for efficient fluid management solutions. Body valves, including ball, gate, and globe types, facilitate precise control of fluid flow, ensuring optimal performance and safety in operational settings.

The versatility of body valves is evident in their application across critical sectors such as oil and gas, water treatment, and chemical processing. The Flow Control Market Report indicates that over 60% of fluid control systems are integrated with advanced valve technologies to enhance efficiency. These valves not only regulate flow but also minimize energy consumption and reduce the risk of leaks and breakdowns, contributing to more sustainable operation. As industries continue to innovate and adapt to changing demands, the essential role of body valves in fluid control systems becomes increasingly clear, driving advancements in efficiency and reliability.

Enhancing System Performance Through Advanced Body Valve Technology

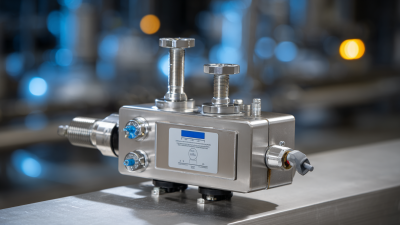

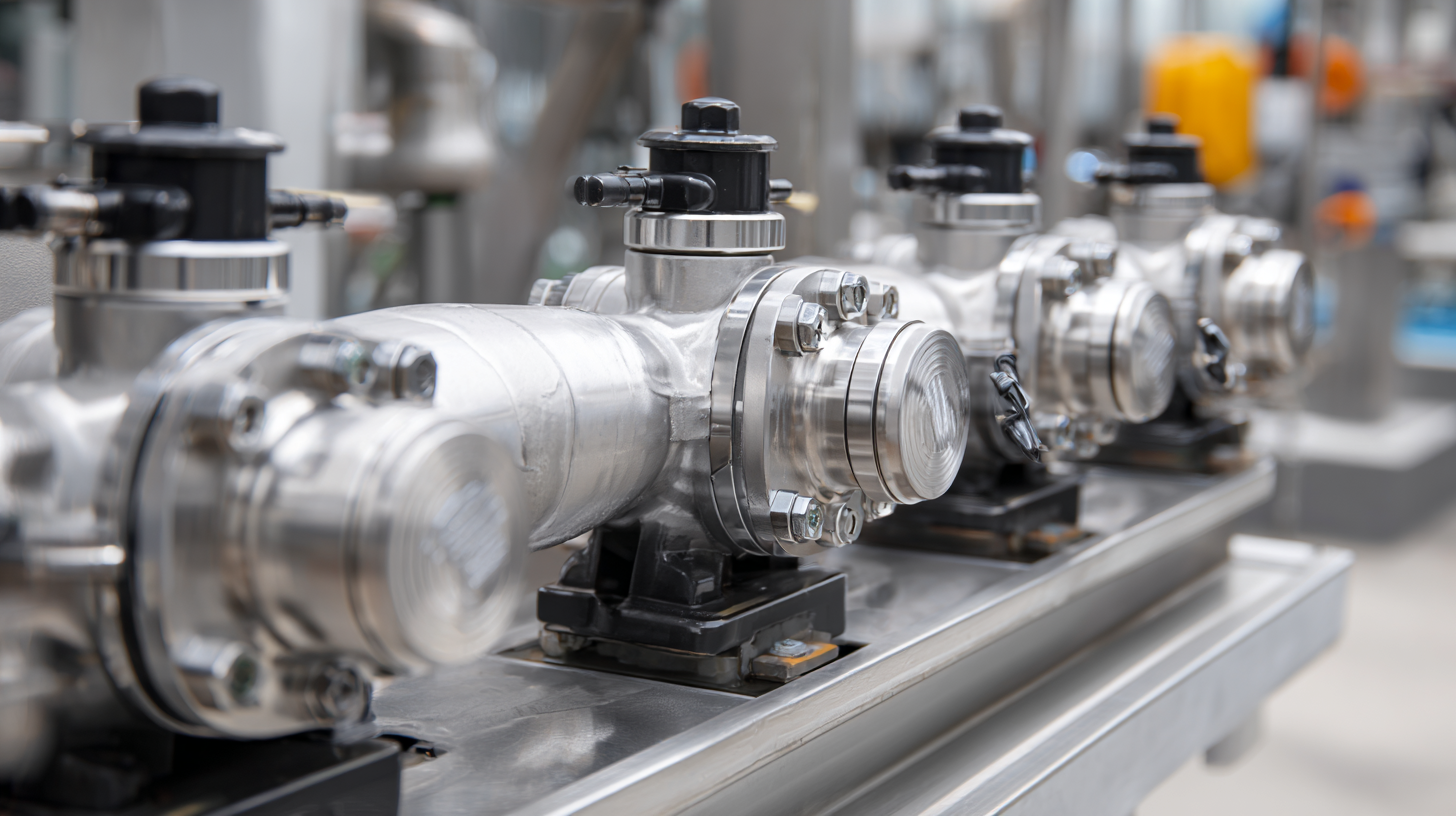

Advanced body valve technology has revolutionized fluid control systems, significantly enhancing their overall performance. According to a report by the International Society for Fluid Dynamics, precise control of flow rates through innovative valve designs can increase system efficiency by up to 30%. This improvement is largely due to advanced materials and smart design features that allow for better sealing and reduced leakage.

Advanced body valve technology has revolutionized fluid control systems, significantly enhancing their overall performance. According to a report by the International Society for Fluid Dynamics, precise control of flow rates through innovative valve designs can increase system efficiency by up to 30%. This improvement is largely due to advanced materials and smart design features that allow for better sealing and reduced leakage.

In addition, the integration of real-time monitoring systems using IoT technology enables predictive maintenance and immediate adjustments based on operational data. A study published in the Journal of Fluid Engineering indicates that systems utilizing electronically actuated valves can achieve response times 50% faster than traditional mechanisms, leading to improved operational safety and reduced downtime. As industries continue to embrace digital transformation, the adoption of advanced body valve technologies is set to play a crucial role in optimizing fluid control systems across various sectors.

The Impact of Valve Design on Flow Efficiency and Energy Consumption

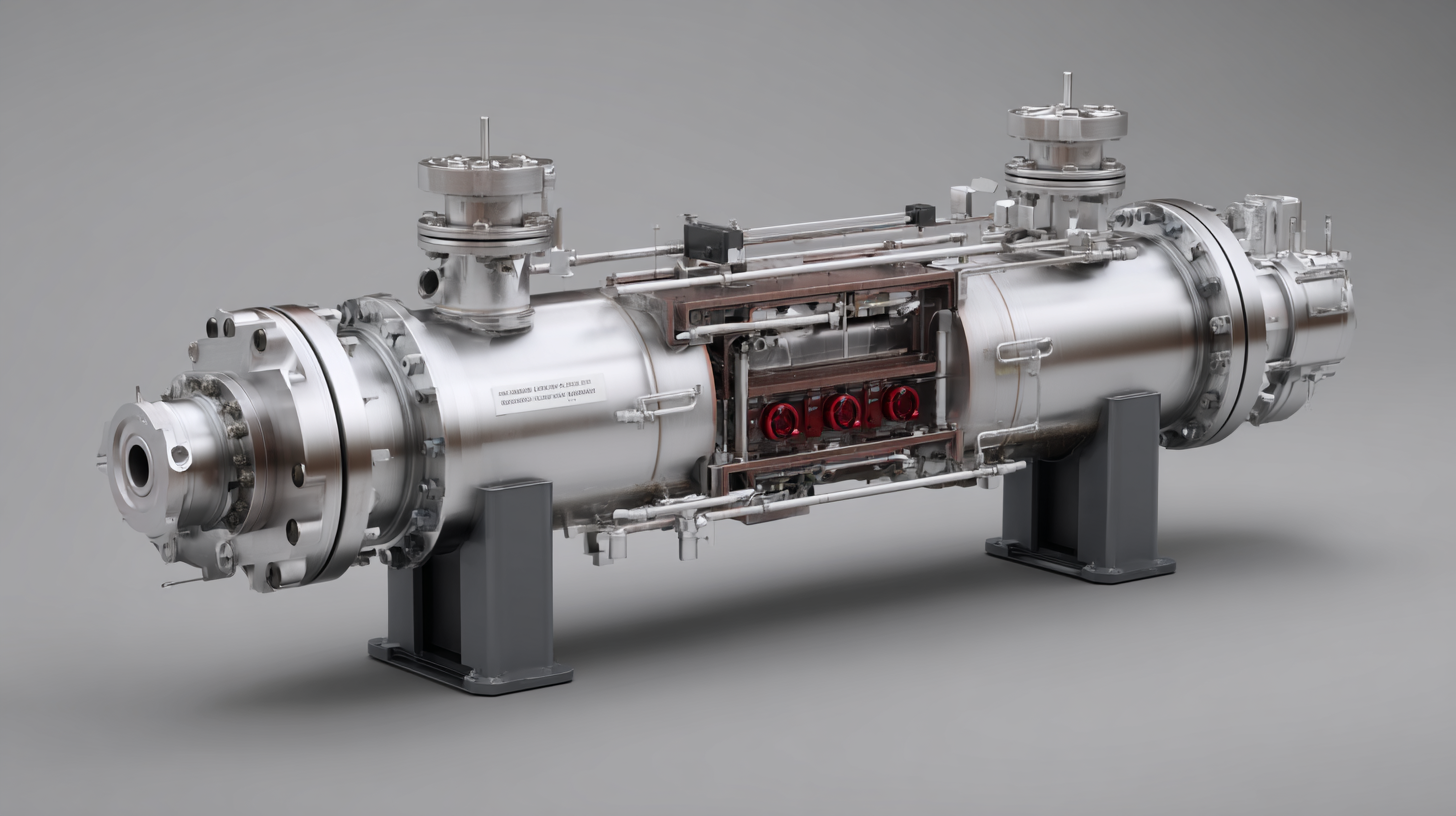

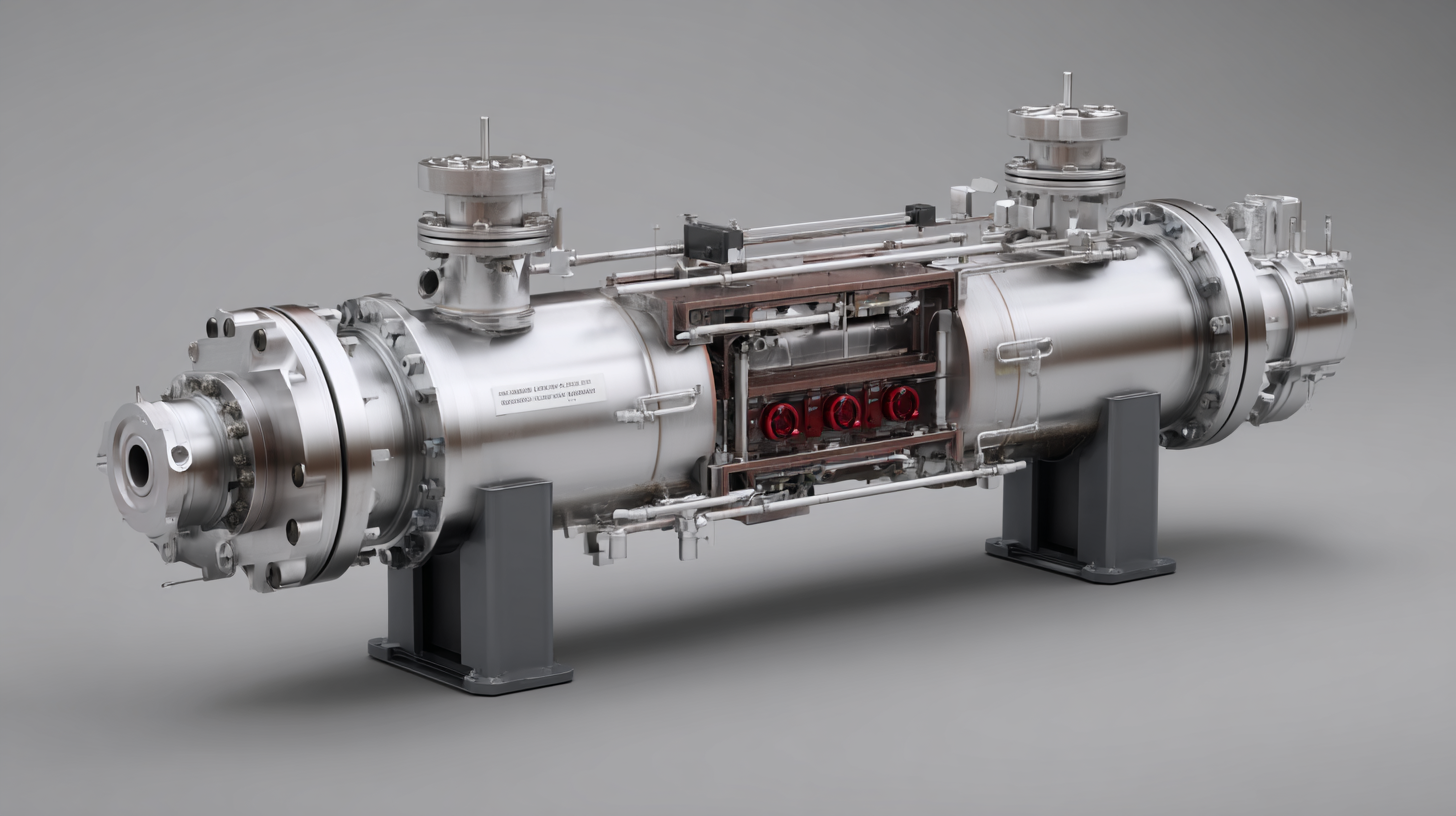

The design of body valves plays a crucial role in optimizing flow efficiency within fluid control systems. An intelligently engineered valve minimizes friction and turbulence, allowing fluids to flow more smoothly and reducing the energy required for pumping. For instance, streamlined valve shapes and strategic placement can significantly enhance the rate of flow while conserving energy. In contrast, poorly designed valves can lead to bottlenecks, which not only hinder performance but also escalate energy costs due to increased pressure drops.

Moreover, advancements in valve materials and technologies contribute to improved energy consumption. Lightweight materials reduce the overall load on pumping systems, while automation features allow for real-time adjustments based on flow conditions. By implementing smart designs and utilizing innovative materials, industries can achieve both heightened flow efficiency and reduced operational costs. The synergy between valve design and energy efficiency underscores the importance of investing in high-quality components for any fluid control application.

Unlocking Efficiency: The Impact of Valve Design on Flow Efficiency and Energy Consumption

Comparative Analysis of Body Valves and Their Applications in Various Industries

Body valves play a crucial role in fluid control systems across various industries, enhancing efficiency and ensuring operational reliability. These valves, which regulate the flow and pressure of fluids in pipelines, come in multiple types such as ball, gate, and butterfly valves. Each type is designed for specific applications, offering unique advantages. For instance, ball valves are ideal for quick shut-off scenarios, while gate valves excel in applications requiring minimal pressure drop.

Body valves play a crucial role in fluid control systems across various industries, enhancing efficiency and ensuring operational reliability. These valves, which regulate the flow and pressure of fluids in pipelines, come in multiple types such as ball, gate, and butterfly valves. Each type is designed for specific applications, offering unique advantages. For instance, ball valves are ideal for quick shut-off scenarios, while gate valves excel in applications requiring minimal pressure drop.

When selecting body valves, it’s essential to consider the specific requirements of your industry. For instance, in the food and beverage sector, sanitary valves that comply with health regulations are vital. Conversely, in oil and gas, reliability under high pressure is paramount. This comparative analysis of body valves illustrates that the right valve choice not only boosts efficiency but also enhances safety and compliance.

Tip: When evaluating body valves, pay attention to the materials used in their construction. Corrosion resistance is critical in harsh environments, so choose valves that are compatible with the fluids they will handle. Additionally, consider the maintenance needs to avoid costly downtimes.

Understanding the applications and features of various body valves can lead to significant operational improvements. Whether in manufacturing, water treatment, or energy, implementing the right valve type can streamline processes and result in cost savings.

Tip: Regularly consult with valve manufacturers to stay updated on innovations and best practices in fluid control systems to maintain optimal performance.

Future Trends in Body Valve Innovations for Fluid Control Solutions

The future of fluid control systems is being shaped significantly by innovations in body valve technology. According to a recent report from MarketsandMarkets, the global valve market is projected to reach $101.5 billion by 2025, driven largely by the integration of smart valve solutions that enhance efficiency and responsiveness in various applications. As industries increasingly prioritize automation and digital integration, body valves are evolving to meet these demands, incorporating features such as IoT connectivity and advanced materials to withstand corrosive environments.

Tip: When selecting body valves for your systems, consider options with built-in sensors for real-time monitoring to optimize operational efficiency and reduce downtime.

Moreover, sustainability is becoming a focal point in the development of new valve technologies. The adoption of energy-efficient designs and materials that minimize fluid loss can significantly impact overall operational costs. The latest innovations also include self-cleaning features and modular designs that allow for easier upgrades and maintenance, aligning with industry trends towards more sustainable practices.

Tip: Research manufacturers that prioritize environmental considerations without compromising quality to ensure you are making a responsible investment in your fluid control systems.

Unlocking Efficiency: How Body Valves Transform Fluid Control Systems - Future Trends in Body Valve Innovations for Fluid Control Solutions

| Dimension |

Current Technology |

Future Innovations |

Potential Benefits |

| Material |

Stainless Steel |

Composite Materials |

Increased durability, reduced weight |

| Sealing Technology |

Traditional Seals |

Magnetic Seals |

Improved leak prevention, longer lifespan |

| Control Systems |

Manual Control |

Smart Automation |

Enhanced precision, energy savings |

| Application Area |

Industrial Equipment |

Renewable Energy Systems |

Sustainability, eco-friendly solutions |

| Size Options |

Standard Sizes |

Customizable Sizes |

Fit for specific applications, versatility |

Advanced body valve technology has revolutionized fluid control systems, significantly enhancing their overall performance. According to a report by the International Society for Fluid Dynamics, precise control of flow rates through innovative valve designs can increase system efficiency by up to 30%. This improvement is largely due to advanced materials and smart design features that allow for better sealing and reduced leakage.

Advanced body valve technology has revolutionized fluid control systems, significantly enhancing their overall performance. According to a report by the International Society for Fluid Dynamics, precise control of flow rates through innovative valve designs can increase system efficiency by up to 30%. This improvement is largely due to advanced materials and smart design features that allow for better sealing and reduced leakage.

Body valves play a crucial role in fluid control systems across various industries, enhancing efficiency and ensuring operational reliability. These valves, which regulate the flow and pressure of fluids in pipelines, come in multiple types such as ball, gate, and butterfly valves. Each type is designed for specific applications, offering unique advantages. For instance,

Body valves play a crucial role in fluid control systems across various industries, enhancing efficiency and ensuring operational reliability. These valves, which regulate the flow and pressure of fluids in pipelines, come in multiple types such as ball, gate, and butterfly valves. Each type is designed for specific applications, offering unique advantages. For instance,