Top Boiler Valve Types to Consider in 2025: A Comprehensive Guide

As we approach 2025, the significance of selecting the right boiler valve cannot be overstated. Boiler valves play a crucial role in ensuring the safety, efficiency, and performance of steam and hot water systems. With the ever-evolving technology and increasing focus on energy efficiency, understanding the various types of boiler valves available in the market becomes essential for both professionals and consumers.

This comprehensive guide will delve into the top boiler valve types to consider, exploring their functionalities, applications, and the advantages they offer. From gate valves to globe valves and check valves, each type serves a specific purpose in regulating flow and controlling pressure within boiler systems. By equipping yourself with knowledge about these vital components, you can make informed decisions that enhance system reliability and operational effectiveness.

In addition, we will discuss emerging trends and innovations related to boiler valve technology that could shape the industry in the coming years. Whether you are a facility manager, engineer, or a homeowner looking to upgrade your heating system, understanding boiler valves is key to optimizing your setup for performance and efficiency in the near future.

Overview of Boiler Valve Functions and Importance

Boiler valves play a pivotal role in the overall efficiency and safety of boiler systems. They are essential components that control the flow of water, steam, and gases within a boiler, ensuring optimal operation and maintaining the desired pressure levels. The primary functions of these valves include regulating steam and water flow, preventing backflow, and enabling safe system shutdowns during emergencies or maintenance. Without properly functioning valves, boilers may encounter severe operational issues, including leaks or failures, which could lead to hazardous situations.

The importance of boiler valve selection cannot be overstated, especially in the context of upcoming technological advancements anticipated in 2025. As industries increasingly prioritize energy efficiency and sustainability, the demand for high-performance valves will grow. Choosing the right type of valve not only enhances the performance of the boiler system but also prolongs its lifespan and reduces maintenance costs. Understanding the various types of boiler valves, such as gate, globe, and ball valves, is crucial for professionals in the field to make informed decisions that align with future trends and operational requirements.

Common Types of Boiler Valves Used in Industrial Applications

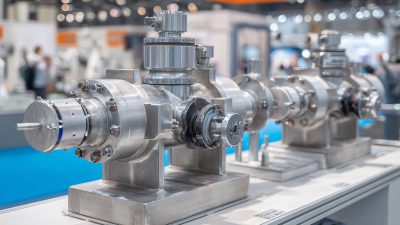

In industrial applications, the selection of appropriate boiler valves is critical for ensuring operational efficiency and safety. Several common types of boiler valves are widely utilized, including globe valves, gate valves, ball valves, and check valves.

According to a recent industry report, globe valves are preferred for their ability to regulate flow and withstand high pressures, making them ideal for steam applications. They provide precise control over the fluid flow, which is essential in maintaining optimal boiler operation.

Gate valves, on the other hand, are primarily used in the on/off control scenario, allowing for minimal pressure drop when fully opened. These valves are typically employed in larger systems where they transition between flow states without requiring frequent adjustments. The 2023 Industrial Valve Market Research Report highlights that ball valves are gaining popularity due to their durability and ease of operation, often employed in scenarios requiring quick shutdowns. Additionally, check valves play a vital role in preventing backflow, thus protecting delicate boiler components from pressure surges. Each valve type contributes significantly to the overall reliability and efficiency of boiler systems, underscoring the importance of selecting the right valve type in industrial settings.

Key Factors to Consider When Selecting Boiler Valves

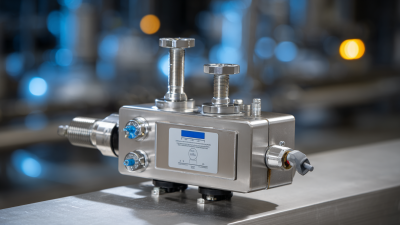

When selecting boiler valves in 2025, it’s essential to consider several key factors to ensure optimal performance and safety. First, assess the application requirements, including pressure, temperature, and medium compatibility. Understanding the specific conditions under which the valve will operate is critical in choosing the right material and design. For example, valves used in high-pressure steam systems must be designed to withstand elevated temperatures and corrosive environments.

Another important consideration is the valve type. There are various types of boiler valves, including gate, globe, ball, and check valves, each serving different purposes. Gate valves are excellent for on-off control, while globe valves are better for throttling. Check valves prevent backflow, providing an additional layer of security in the system. Selecting the appropriate valve type can significantly impact the efficiency and safety of the boiler system.

**Tips:** When deciding on the valve type, consult with industry experts or reference credible guides to gain insights into the latest technologies and standards. Additionally, always evaluate the reliability of suppliers and ensure that the valves meet the necessary certifications. Regular maintenance and inspection of the valves are also crucial to prolong their lifespan and maintain the integrity of the boiler system.

Latest Innovations in Boiler Valve Technology for 2025

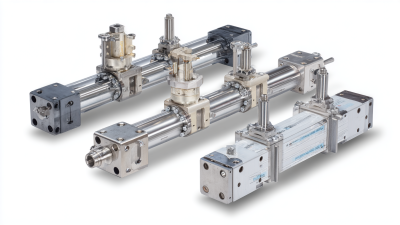

In 2025, the landscape of boiler valve technology is poised for remarkable advancements, driven by the need for increased efficiency and enhanced safety in industrial applications. One of the cutting-edge innovations is the integration of IoT (Internet of Things) technology into boiler valve systems. This allows for real-time monitoring and remote control capabilities, enabling operators to detect abnormalities and respond to potential failures before they escalate. The ability to analyze data collected from these systems enhances predictive maintenance strategies, reducing downtime and operational costs.

Moreover, advancements in materials science are leading to the development of corrosion-resistant and high-temperature tolerant valve designs. These materials can withstand more extreme operating conditions, thereby prolonging the lifespan of boiler systems and reducing the frequency of replacements. Additionally, the focus on sustainability has driven innovations towards environmentally friendly manufacturing processes for valves, ensuring that the production methods themselves are as efficient as the products they create. Enhanced seals and valve geometry are also being explored to improve flow efficiency and reduce energy consumption, aligning with the industry’s commitment to green practices.

Maintenance and Inspection Practices for Boiler Valves

Maintaining boiler valves is a critical aspect of ensuring the efficiency and safety of boiler systems. Proper maintenance practices can significantly reduce downtime and extend equipment lifespan. According to a report by the American Society of Mechanical Engineers, over 30% of boiler failures are attributed to valve-related issues. Regular inspection and maintenance help identify signs of wear, corrosion, or leakage in valves, which can prevent costly repairs and unsafe operating conditions. Implementing routine checks every six months can enhance performance and reliability.

Additionally, leveraging technology such as predictive maintenance can optimize inspection schedules. A study published in the Journal of Pressure Vessel Technology indicates that predictive maintenance techniques can increase the reliability of boiler systems by over 25%. This approach utilizes data analysis to anticipate potential failures, allowing for timely interventions before issues develop. By incorporating these practices, facilities can ensure that their boiler valves function at peak performance, avoiding interruptions and contributing to overall operational efficiency.

Top Boiler Valve Types to Consider in 2025: A Comprehensive Guide

| Valve Type |

Material |

Temperature Range (°C) |

Pressure Rating (PSI) |

Applications |

| Gate Valve |

Cast Iron |

-20 to 200 |

150 |

Steam and Water |

| Ball Valve |

Stainless Steel |

-60 to 200 |

300 |

Oil and Gas |

| Globe Valve |

Brass |

-10 to 150 |

250 |

Water and Steam |

| Check Valve |

PVC |

0 to 60 |

150 |

Wastewater Systems |

| Butterfly Valve |

Aluminum |

-40 to 80 |

150 |

HVAC Systems |