Why Choose Industrial Water Valves for Your Business Needs?

In the competitive landscape of industrial operations, the importance of reliable water management cannot be overstated. Industrial water valves play a crucial role in regulating the flow and pressure of water used in various processes. According to a report by Grand View Research, the global industrial valves market is projected to reach $85 billion by 2025, highlighting the growing demand for these essential components.

Experts emphasize the value of choosing the right products for efficiency. Dr. Emily Carter, a leading authority in fluid mechanics, states, "Investing in high-quality industrial water valves can significantly reduce operational costs and enhance system reliability." This perspective aligns with findings from the International Water Association, which notes that optimized water management can lead to up to 30% cost savings for businesses.

However, selecting industrial water valves can be complex. There are varying standards and specifications, making it necessary for companies to consider their unique needs. Some businesses may overlook these aspects, risking subpar performance. In a field where precision and durability are paramount, reflecting on these choices is vital. Higher initial costs may lead to better long-term outcomes, but many still hesitate to commit.

Key Features of Industrial Water Valves for Business Applications

Industrial water valves play a vital role in various business applications. They control water flow efficiently within systems. Key features make them particularly useful for industries. Durability is a crucial aspect. These valves can withstand harsh conditions. This feature ensures long-term performance, reducing the need for replacements.

Another important characteristic is their adaptability. Industrial water valves can be customized for specific applications. They can handle high pressures and temperatures, providing versatility. Furthermore, many valves offer user-friendly designs. This allows for easy installation and maintenance. However, not every valve meets all business needs.

Consider the size and type of your system. Choosing the wrong valve might lead to inefficiencies. Regular assessments and adjustments are important. It’s vital to understand the unique requirements of your operations. Sometimes, businesses overlook this. This can result in unexpected downtime or failures. Taking time to evaluate can prevent costly setbacks.

Why Choose Industrial Water Valves for Your Business Needs? - Key Features of Industrial Water Valves for Business Applications

| Feature |

Description |

Benefits |

| Durability |

Designed to withstand harsh industrial environments, resistant to corrosion and damage. |

Lower maintenance costs and longer lifespan. |

| Flow Control |

Accurate regulation of water flow, preventing system overload and ensuring efficiency. |

Improved operational efficiency and reduced risk of flooding. |

| Versatility |

Suitable for various applications, including high-pressure systems and different fluids. |

Flexibility to adapt to changing business needs. |

| Safety features |

Equipped with safety mechanisms to prevent leaks and failures. |

Enhanced safety for personnel and equipment. |

| Easy Maintenance |

Design allows for straightforward inspection and maintenance procedures. |

Reduced downtime and labor costs. |

Advantages of Using Industrial Water Valves in Various Industries

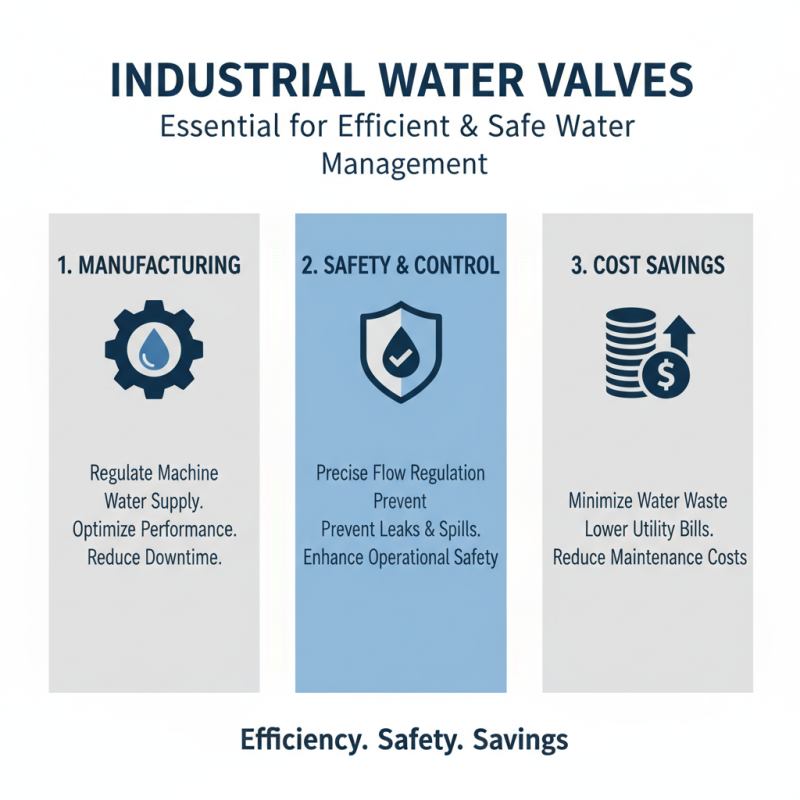

Industrial water valves play a crucial role in various sectors. They help manage water flow efficiently and safely. In manufacturing, for example, these valves regulate water supply to machines. This ensures optimal performance and reduces downtime. The precise control they offer can lead to significant cost savings.

In the agricultural industry, water valves maintain irrigation systems. They manage water distribution to crops, ensuring growth and sustainability. A malfunction in a valve can lead to water wastage or inadequate supply. This detail highlights the need for reliable equipment. Yet, despite their importance, some businesses overlook regular maintenance.

Water valves are essential in construction as well. They control water pressure for tools and cooling systems. However, not all companies prioritize high-quality materials. This sometimes results in leaks or failures. Businesses must evaluate their valve choices carefully. Investing in the right valves can prevent costly repairs and delays.

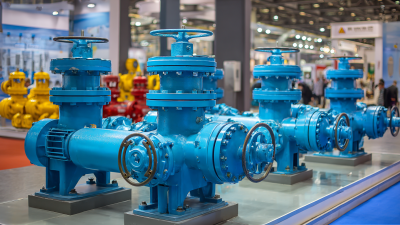

Types of Industrial Water Valves and Their Specific Uses

Industrial water valves play a crucial role in various applications. There are several types, each designed for specific needs.

Gate valves are commonly used to control flow. They offer a tight seal, preventing leaks.

However, they may not be suitable for frequent operation.

Ball valves, on the other hand, allow quick shut-off. Their simple design can facilitate ease of use, yet they can wear down over time.

Choke valves are essential in regulating flow rate. These valves help maintain pressure, ensuring stability in systems. They can be complex, requiring regular maintenance.

Butterfly valves are known for their lightweight design. They can handle large volumes, but may not seal as well in all conditions.

It's important to choose the right type for your application.

Some businesses overlook the need for regular checks. Neglecting maintenance can lead to inefficiencies.

It’s not always easy to determine the best valve type. Consider your specific requirements and environment. This will lead to better performance and longevity.

Choices matter; don't rush the decision-making process.

Factors to Consider When Selecting Water Valves for Your Business

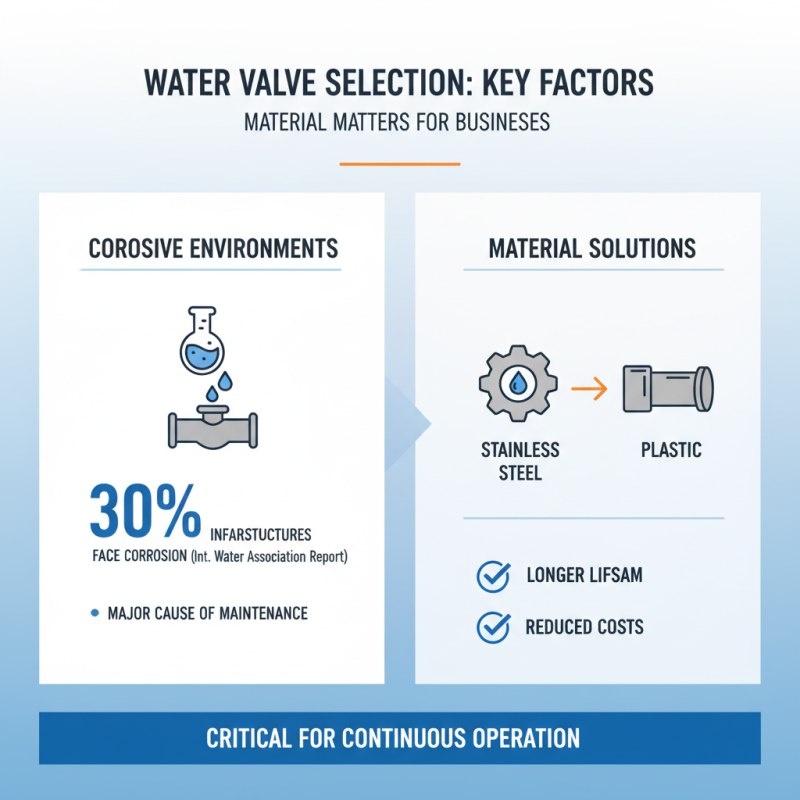

When selecting water valves for your business, consider multiple crucial factors. One key aspect is the valve material. Many industries require valves that can withstand corrosive environments. According to a report by the International Water Association, about 30% of infrastructures face corrosion issues. Choosing stainless steel or plastic can significantly reduce maintenance costs. The right material can ensure a longer lifespan, which is critical for continuous operations.

Another important factor is the valve type. Gate valves, globe valves, and ball valves serve different functions. A study conducted by the American Water Works Association found that 40% of water supply failures are due to valve malfunction. This emphasizes the importance of selecting the right type based on pressure, flow rates, and specific applications. Businesses should also consider automation features. Smart valves can enhance efficiency, but their complexity may require specialized training for staff.

In addition, pressure ratings are often overlooked. Valves must support the system's pressure requirements. A miscalculation could lead to system failures. It's vital to assess the operating conditions carefully. Many companies focus on cost, but spending a little extra on a reliable valve can save significant future headaches. Choosing the wrong one could lead to leaks, downtime, and additional expenses.

Maintenance Tips for Ensuring Longevity of Industrial Water Valves

Industrial water valves are essential in many businesses. Their proper functionality is vital for smooth operations. To ensure the longevity of these valves, maintenance is crucial. Regular checks can prevent costly downtimes.

One important tip is to conduct routine inspections. Look for leaks and corrosion. A small leak can lead to major issues over time. If you notice anything unusual, address it immediately. Neglecting these signs may lead to expensive repairs down the line.

Regularly cleaning the valves is another key aspect. Dirt and debris can cause them to malfunction. Use a soft brush and mild detergent to clear away any buildup. Remember, a clean valve is a functional valve. Take note of how often you perform these tasks. Adjust your schedule based on operational demands.