How to Choose the Right Valves for Your Industrial Applications

In the industrial sector, the selection of the right valves is critical for

optimizing operational efficiency and ensuring safety. According to a report by the

Global Market Insights, the industrial valve market is projected to surpass

$95 billion by 2026, driven by rising demand in

oil and gas, water treatment, and power generation applications. Valves play a pivotal role in regulating

flow and pressure within systems, making their appropriate selection essential for minimizing leaks and

energy losses. As industries increasingly prioritize

sustainability and compliance with stringent environmental regulations,

the need for high-performance valve solutions has never been more pronounced.

This article aims to provide insights into the various types of valves and the

key considerations to keep in mind when choosing the most suitable option for

specific industrial applications.

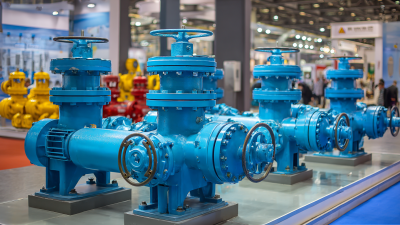

Understanding Different Types of Valves and Their Functions

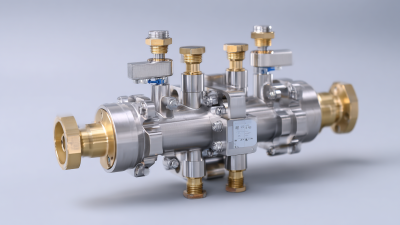

When selecting valves for industrial applications, it is crucial to understand the different types of valves and their functions. Generally, valves can be classified into several categories, including globe valves, ball valves, gate valves, and check valves. Each type serves distinct purposes in fluid control. For example, globe valves are typically used for throttling flow, while ball valves are preferred for their quick on-off operation. According to industry reports, the global industrial valves market is projected to grow steadily, with major drivers such as the increasing demand for automation in manufacturing processes.

Moreover, the materials and designs of the valves play a significant role in their performance and suitability for specific applications. For instance, high-performance plastics and alloys are often used in corrosive environments, while stainless steel may be more appropriate for high-pressure applications. A study highlighted that improper valve selection can lead to significant operational inefficiencies and increased maintenance costs, urging industries to invest in proper valve engineering. Understanding these nuances not only ensures optimal operation but also enhances safety and longevity in industrial systems.

Key Factors to Consider When Selecting Valves for Your Industry

When selecting valves for industrial applications, several key factors must be considered to ensure optimal performance and reliability. Firstly, understanding the specific requirements of the application is crucial. This entails evaluating the type of media being handled, the temperature and pressure conditions, as well as the flow rate. Different materials and valve types, such as ball, gate, or globe valves, can affect how well a valve performs under these varying conditions.

Another important consideration is the valve's compatibility with your system. This includes assessing the connection types, such as threaded, flanged, or weld types, as well as the valve's size relative to the piping network. Additionally, the operational mechanism of the valve, whether manual or automated, plays a significant role in efficiency and ease of maintenance. By carefully evaluating these factors, industries can select valves that not only meet regulatory standards but also enhance overall operational effectiveness and longevity of their systems.

How to Choose the Right Valves for Your Industrial Applications - Key Factors to Consider When Selecting Valves for Your Industry

| Valve Type |

Application |

Pressure Rating (PSI) |

Temperature Range (°F) |

Material |

| Ball Valve |

Oil & Gas |

1500 |

-20 to 250 |

Stainless Steel |

| Gate Valve |

Water Treatment |

2000 |

-10 to 300 |

Cast Iron |

| Globe Valve |

Power Generation |

3000 |

-40 to 400 |

Carbon Steel |

| Check Valve |

Chemical Processing |

1500 |

0 to 250 |

PVC |

| Butterfly Valve |

HVAC |

150 |

-20 to 180 |

Aluminum |

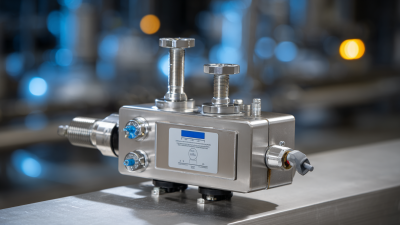

Evaluating Material Compatibility for Valves in Harsh Environments

When selecting valves for industrial applications, especially in harsh environments, evaluating material compatibility is crucial. Valves must withstand not only the chemical properties of the substances they control but also the physical stresses they may encounter, such as temperature extremes and mechanical wear. For instance, recent studies into composite materials have demonstrated significant advancements, showcasing composite heart valve prostheses that exhibit exceptional fatigue resistance with no noticeable performance degradation after exposure to extensive operational cycles. This illustrates the potential of composite materials in applications requiring durability and longevity.

**Tips:** Consider materials that offer high fatigue resistance and corrosion resistance when choosing valves for demanding environments. Also, make sure to assess the potential impact of temperature fluctuations on material integrity to avoid premature failure.

Furthermore, the recent evaluations of hydrogen gas transport capabilities in pipelines underline the importance of choosing valves that can handle the specific demands of gas applications. This highlights the need for rigorous testing and modeling approaches to ensure that valves not only perform effectively but also contribute to the safety and efficiency of industrial systems. Selecting the right materials, such as those demonstrated in innovative applications, can greatly enhance the performance and reliability of valves in challenging conditions.

**Tips:** Always conduct thorough research on the latest material technologies and their suitability for your specific application to ensure optimal performance under all conditions.

Assessing Performance Metrics: Pressure, Temperature, and Flow Rates

When selecting the right valves for industrial applications, assessing performance metrics such as

pressure,

temperature, and

flow rates is crucial. Each of these factors directly influences the

valve's functionality and suitability for specific tasks. Pressure ratings indicate the maximum pressure

during operations; exceeding this can lead to valve failure or leakage. Therefore, it’s essential to select

a valve that can withstand the operational pressure of the system to ensure safety and reliability.

Temperature is another critical metric to consider. Different valve materials have varying temperature

tolerances, which means it’s vital to match the valve to the thermal environment in which it will operate.

For instance, high-temperature applications require valves made from materials like

stainless steel or specialized alloys to prevent deformation or damage.

Additionally, understanding flow rates is essential for properly sizing a valve, as too large a valve can

lead to inefficiencies while a too-small valve can restrict flow, causing pressure drops. By carefully

evaluating these performance metrics, industries can ensure optimal operation and longevity of their

valve systems.

Maintenance and Longevity: Choosing Durable Valves for Industrial Use

When selecting valves for industrial applications, one of the critical aspects to consider is their maintenance and longevity. Durable valves not only ensure consistent performance but also reduce the frequency and costs associated with repairs and replacements. It is essential to choose materials that can withstand the specific operating conditions, such as temperature, pressure, and corrosive environments. For instance, stainless steel and high-performance plastics are often preferred for harsh conditions due to their resistance to corrosion and wear.

In addition to material selection, the design and construction of the valve play a significant role in its lifespan. Look for valves that offer features like self-cleaning mechanisms or easy-to-replace components, which can enhance their durability and simplify maintenance tasks. Regular inspections and timely servicing are vital to identify potential issues early on. By investing in high-quality, durable valves and following a proactive maintenance plan, industries can significantly improve the reliability of their operations while minimizing downtime and costs related to valve failures.