How to Choose the Right Valve for Your Industry Needs?

Choosing the right valve is crucial for various valve industries. Each application requires specific features for optimal performance. The right valve can enhance efficiency, ensure safety, and reduce costs in manufacturing processes.

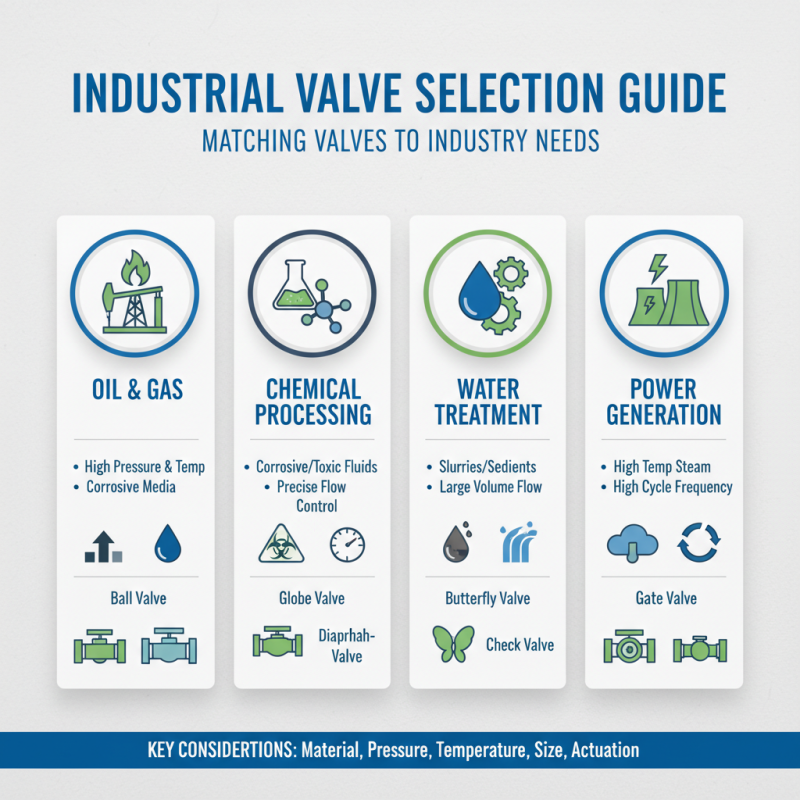

Valves come in many types, like ball, gate, and check valves. Each type serves different purposes across diverse sectors. For instance, the chemical industry often needs valves that can handle corrosive substances. In contrast, water treatment plants require durable valves that prevent leaks and can withstand pressure.

However, selecting a valve isn't always straightforward. It involves assessing flow rates, pressures, and the materials used. This process can be overwhelming, leading to mistakes. Valve industries demand careful consideration to avoid costly errors. A wrong choice can disrupt operations and lead to safety hazards. It's essential to reflect on the specific needs of your application before making a decision.

Understanding Different Types of Valves and Their Applications

Choosing the right valve for specific industrial applications is essential. Each type of valve serves a unique purpose. For instance, globe valves are ideal for regulating flow, while ball valves are best for quick shut-off. According to industry reports, the global valve market is projected to reach $80 billion by 2025, reflecting growing demand across various sectors.

In the oil and gas industry, gate valves are commonly used due to their ability to handle high pressures. Meanwhile, butterfly valves are favored in water treatment plants because of their lightweight and cost-effectiveness. However, some industries may overlook the importance of material selection. Using the wrong material can lead to corrosion and failures.

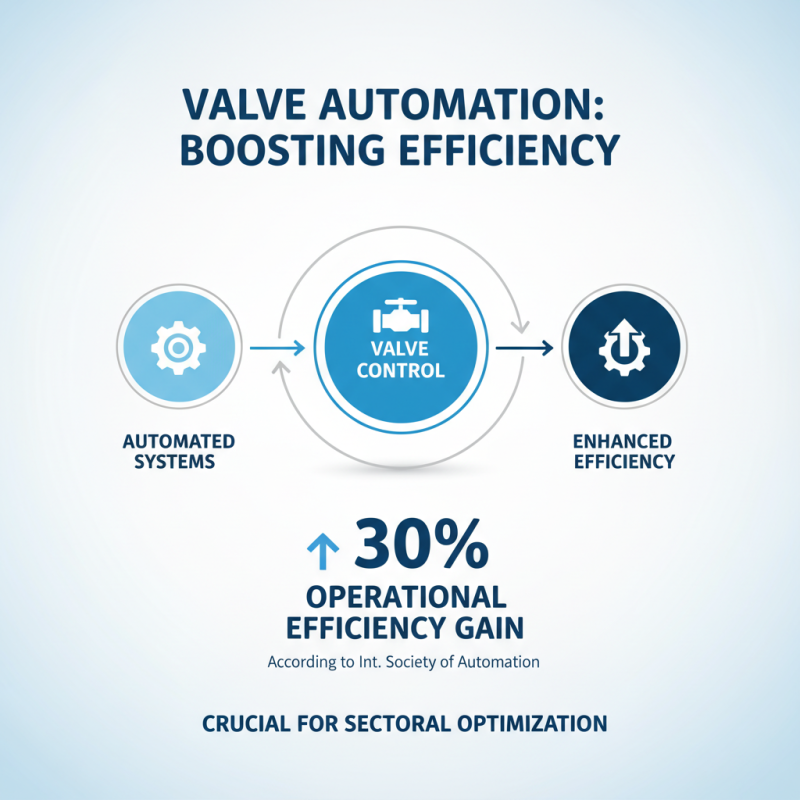

The rise of automation leads to increased need for actuated valves. These valves enhance efficiency but can be complicated to integrate. There’s a gap in understanding how to balance automation with manual control. While the push for advanced technology is strong, some operations may benefit from traditional methods. Adaptation remains a critical consideration for industries.

Evaluating Valve Materials and Design for Durability and Performance

When selecting a valve, material and design are crucial. Different industries face unique challenges. For instance, valves in chemical processing must resist corrosion. Stainless steel or specialized alloys are common choices. Yet, even these materials can fail under extreme conditions. Proper evaluation is essential.

Examining the valve design is equally important. A simple design may enhance flow efficiency, yet complexity can lead to increased maintenance issues. Consider how gaskets and seals contribute to longevity. Sometimes, a robust metallic seal may be more reliable than softer materials. Observations in real-life applications often reveal unexpected wear patterns. Regular inspection is necessary to identify potential problems early.

Durability does not always equate to higher costs. Sometimes, cheaper materials can perform well if designed correctly. Understanding specific performance metrics can guide your decision-making. Relying on past experiences often leads to better choices. Remember, trial and error is part of refining your valve selection process. Each choice should be informed, but not set in stone.

How to Choose the Right Valve for Your Industry Needs? - Evaluating Valve Materials and Design for Durability and Performance

| Valve Type |

Material |

Temperature Range (°C) |

Pressure Rating (bar) |

Applications |

| Ball Valve |

Stainless Steel |

-20 to 150 |

10 |

Water, Oil, Gas |

| Gate Valve |

Cast Iron |

-10 to 120 |

16 |

Water Supply |

| Check Valve |

PVC |

0 to 45 |

6 |

Drainage, Wastewater |

| Globe Valve |

Brass |

-20 to 130 |

20 |

Heating Systems |

| Butterfly Valve |

Aluminum |

-10 to 80 |

10 |

HVAC, Water Treatment |

Comparing Valve Sizing and Pressure Ratings for Optimal Functionality

Choosing the right valve requires careful consideration of sizing and pressure ratings. Proper sizing ensures that the valve can handle the required flow rate and pressure. A valve that is too small may restrict flow, while one that is too large can lead to inefficiencies. Understanding the application’s fluid dynamics is critical.

Pressure ratings are equally important. Each valve has a maximum pressure limit. Exceeding this limit can result in failure or leaks. Therefore, always analyze the system’s operating pressure. For high-pressure applications, a valve with a higher rating is necessary. This ensures safety and reliability.

Sometimes, people overlook these details. Many assume standard sizes will fit all applications. This can lead to operational issues. It’s important to think critically about these choices. Consider consulting with experts or using simulation tools for better insights. Invest time in understanding specific needs. This will help avoid costly mistakes and enhance functionality.

How to Choose the Right Valve for Your Industry Needs?

This chart compares different valve types based on their sizing and pressure ratings, which are crucial for optimal functionality in various industrial applications.