How to Choose the Right Waste Valve for Your Needs?

Choosing the right waste valve is crucial for various applications. A waste valve controls the flow of waste materials during processes. It plays a significant role in efficiency and safety.

There are many types of waste valves available in the market. Each type serves different needs. Some are designed for harsh environments. Others cater to easier maintenance or specific industry standards. Selecting the correct valve is not always straightforward.

Consider factors such as material compatibility and pressure ratings. Dimensions are also vital to fit your system perfectly. Sometimes, factors like cost or availability might influence your decision. Reflecting on these aspects is necessary for optimal performance and longevity. A wrong choice may lead to leaks or operational inefficiencies.

Understanding Different Types of Waste Valves Available in the Market

When selecting a waste valve, it's crucial to understand the types available in the market. Common options include

ball valves,

gate valves, and

butterfly valves. Each serves a specific purpose and has its own strengths and weaknesses.

For instance,

ball valves provide quick shut-off and are ideal for high-pressure systems. However, they may not handle sediment well due to their design.

Gate valves, on the other hand, are excellent for on/off control but can be slow to operate. A recent industry report highlighted that

30% of users reported difficulties with gate valves in applications with frequent cycling.

Butterfly valves are lightweight and compact, making them suitable for industrial settings. Yet, their sealing capabilities may vary significantly.

This inconsistency could lead to leaks if not chosen carefully.

Choosing the right valve requires considering the application specifics. Factors such as pressure, temperature, and flow requirements are vital. A survey indicated that over

40% of engineers struggled with selecting valves that meet all operational needs. It's essential to reflect on your system's demands.

The wrong choice can lead to inefficiencies and unexpected costs. Each valve type has its place, but matching the right one with your application is vital for success.

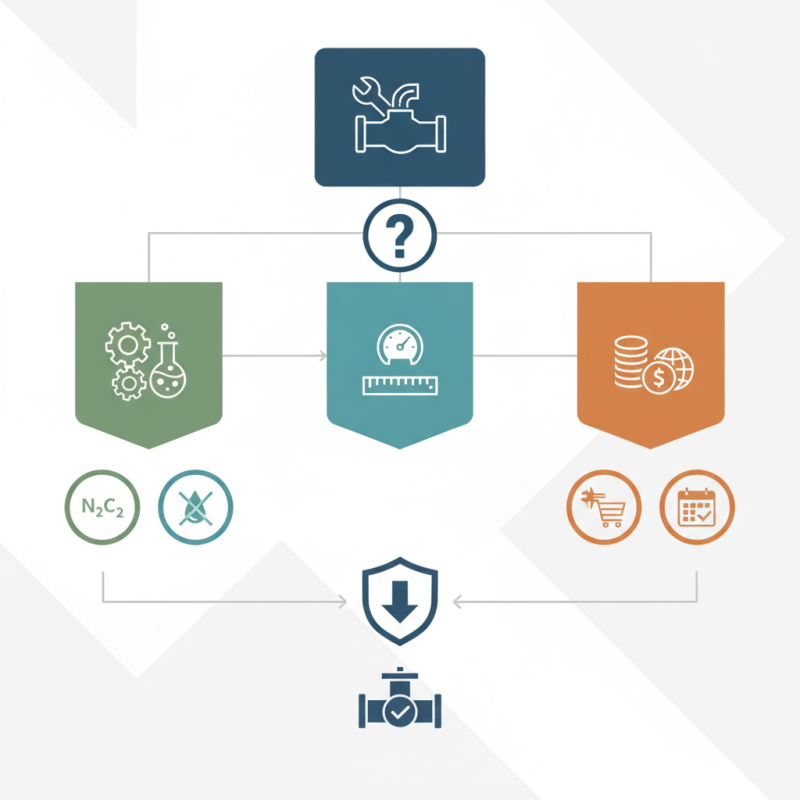

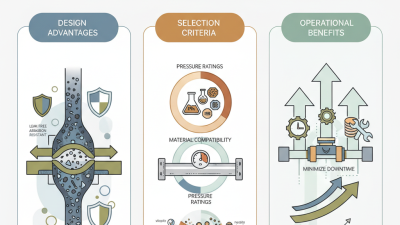

Key Factors to Consider When Selecting a Waste Valve for Your Application

Choosing the right waste valve is crucial for effective waste management. Key factors include valve type, material, and pressure rating. Different applications require specific valve features. For example, a high-pressure system needs valves that can withstand extreme conditions. Evaluate your application’s needs before making a decision.

Material selection is another essential aspect. Valves can be made from metal, plastic, or rubber. Each material has its strengths and weaknesses. Metal valves are durable but may corrode. Plastic can resist certain chemicals but may not handle high temperatures. It’s important to think about long-term use and maintenance.

Consider the installation and operational environment too. Ease of access can affect routine checks. If not accessible, maintenance may be overlooked. Think about how your choice fits into your existing setup. A wrong decision may lead to leaks or system inefficiencies. Reflect on these factors carefully to ensure a wise choice.

Evaluating the Size and Compatibility of Your Waste Valve Options

When selecting the right waste valve, size and compatibility are crucial factors. An ill-fitting valve can lead to leaks and operational inefficiencies. According to a recent industry report, nearly 25% of waste management failures stem from improper valve sizing. Ensuring that the waste valve matches the system’s specifications protects against costly repairs and downtime.

To find the right fit, start by measuring the pipe diameter and flow rate. Commonly, waste valves need to accommodate pressure ranges between 5 to 150 psi. Yet, many overlook these parameters. Analysts have noted that 30% of installations face compatibility issues due to oversight in these fundamental details. Additionally, if your system operates in extreme conditions, such as high temperatures or corrosive environments, this must be factored into your choice.

Compatibility extends beyond the technical specifications. Assess the materials used in your valve. This can impact performance significantly. A valve made from incompatible materials can corrode, leading to potential system failures. Reports highlight that improper material selection can reduce system lifespan by up to 40%. Therefore, evaluating all aspects of size and compatibility is not just advisable but essential for a reliable waste management system.

How to Choose the Right Waste Valve for Your Needs?

| Valve Type |

Size (inches) |

Material |

Pressure Rating (psi) |

Compatibility |

| Ball Valve |

2" |

PVC |

150 |

Water, Chemicals |

| Gate Valve |

3" |

Stainless Steel |

300 |

Water, Wastewater |

| Check Valve |

1.5" |

Bronze |

200 |

Gas, Water |

| Butterfly Valve |

4" |

Plastic |

150 |

Water, Light Chemicals |

| Plug Valve |

2.5" |

Cast Iron |

150 |

Oil, Gas |

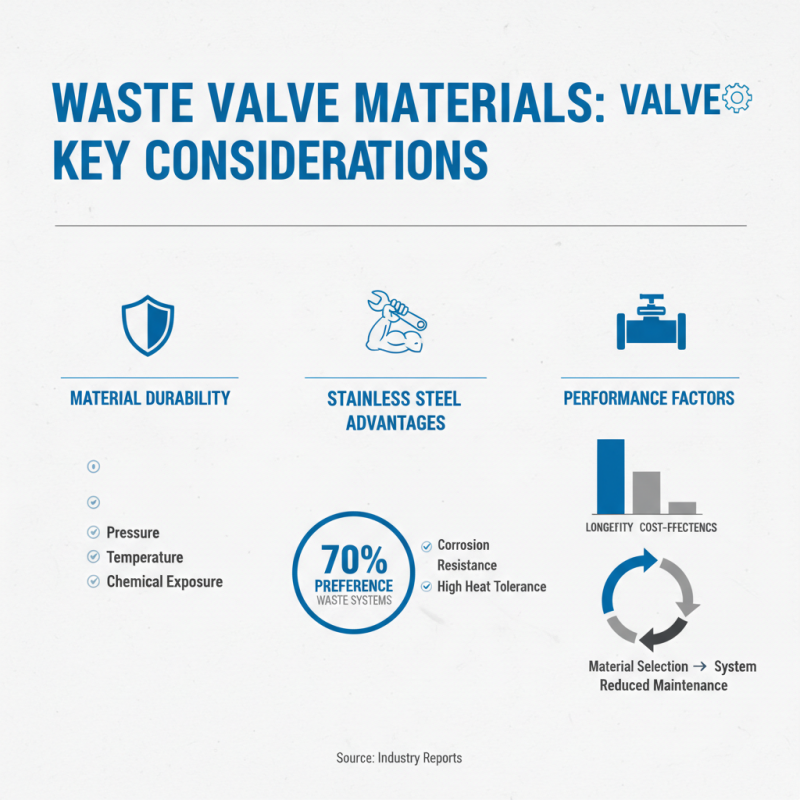

Examining Material Durability and Performance for Waste Valve Selection

Selecting the right waste valve involves careful consideration of material durability and performance. Various materials exhibit different strengths and weaknesses under conditions like pressure, temperature, and chemical exposure. For instance, stainless steel valves boast excellent resistance to corrosion and high temperatures, making them suitable for many harsh environments. According to industry reports, about 70% of waste systems prefer stainless steel due to its longevity.

However, not all roles require expensive materials. In less demanding settings, PVC valves might suffice. They are lightweight and resistant to a range of chemicals, but they can be prone to cracking under extreme conditions. Surveys reveal that nearly 40% of users face issues with plastic valves failing prematurely. It's essential to analyze the specific application before making a choice.

Some users overlook the importance of compatibility between the material and the waste being handled. Misalignment can lead to leaks or even catastrophic failures. Ignoring manufacturer guidelines contributes to these problems. A detailed review of performance metrics can illuminate potential shortcomings that might otherwise be overlooked. The need for introspection in material selection may not be obvious, but it can prevent costly errors in the long run.

Maintenance and Installation Tips for Optimal Waste Valve Functionality

Choosing the right waste valve is crucial for ensuring optimal functionality. Proper installation and maintenance are key components in keeping the valve working effectively. If improperly installed, issues such as leaks or blockages can occur.

Regularly inspect your waste valve. Look for any signs of wear or corrosion. A small leak can lead to significant problems over time. It’s a good idea to check the seals and gaskets every few months. Replace them if they appear damaged.

Tip: Always refer to the manufacturer’s guidelines for installation. Use proper tools during installation to avoid damaging the valve. Pay attention to the torque specifications to ensure a secure fit.

Another important aspect is routine cleaning. Build-up can hinder functionality. A simple flush can often resolve minor blockages. However, if you notice persistent issues, it may be time to reconsider your valve choice.

Waste Valve Selection: Performance Comparison