How to Choose the Right Actuator Valve for Your Industrial Application

In industrial applications, selecting the right actuator valve is crucial for ensuring optimal performance and efficiency. An actuator valve serves as the vital component that controls the flow of fluids and gases within various systems, making it essential to choose one that meets the specific requirements of your operation. With numerous types of actuator valves available, ranging from electric to pneumatic and hydraulic options, understanding the distinct characteristics and functionalities of each type is key to making an informed decision. This guide will offer insights into the critical factors to consider, such as compatibility with existing systems, response time, and maintenance needs, enabling you to identify the best actuator valve that not only enhances your processes but also aligns with your operational goals. Whether you're working in manufacturing, water treatment, or chemical processing, learning how to select the appropriate actuator valve can significantly impact your system's reliability and efficiency.

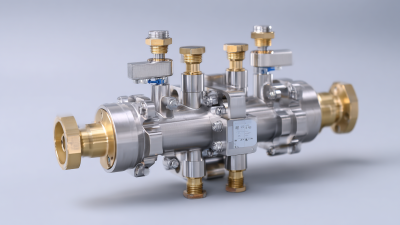

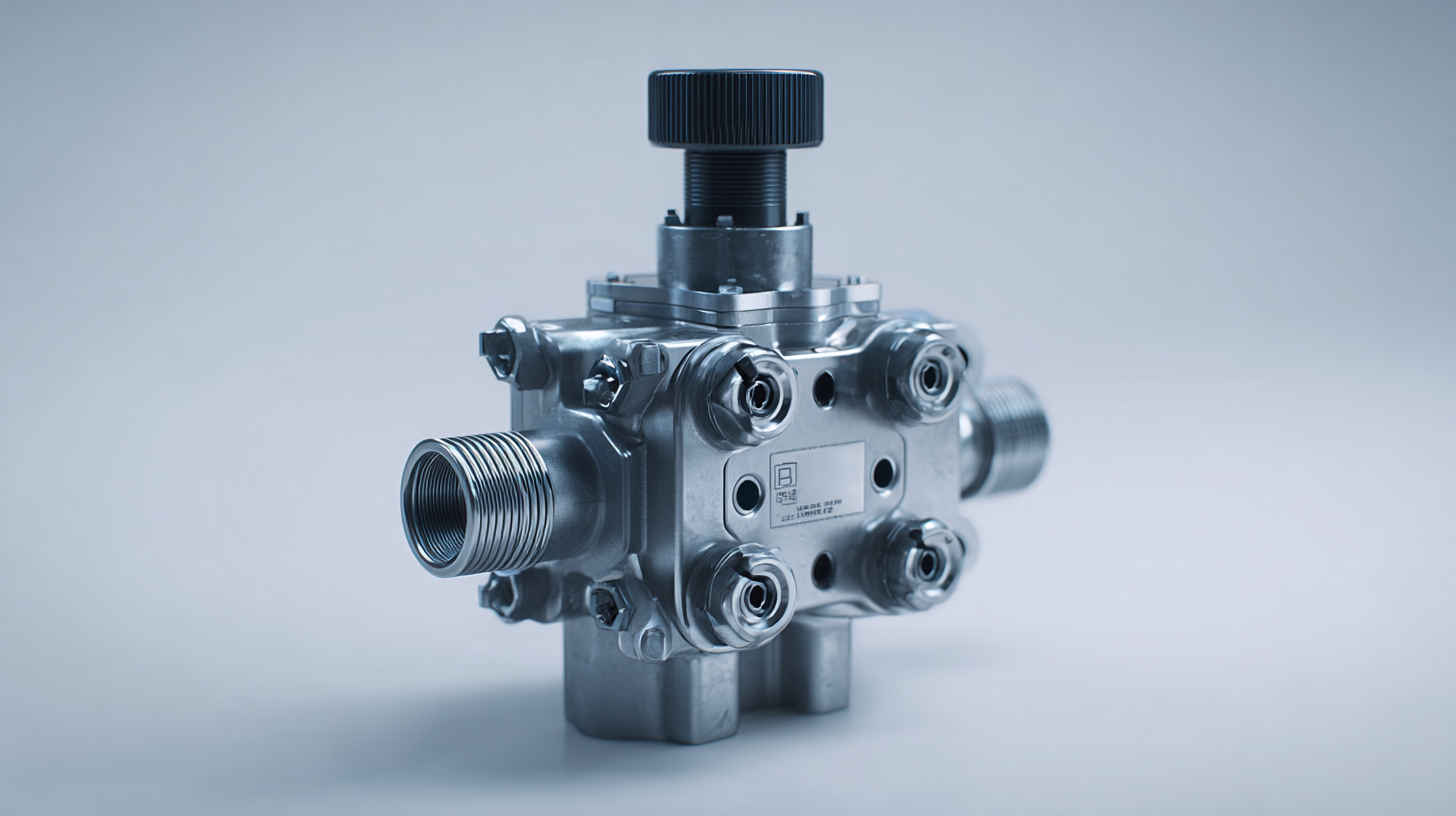

Understanding Different Types of Actuator Valves for Industrial Use

When selecting the right actuator valve for industrial applications, it is essential to understand the various types available in the market. It's important to note that actuator valves can be broadly categorized into three types: pneumatic, electric, and hydraulic. According to the Global Actuator Valve Market Report, the pneumatic actuator segment accounts for over 40% of the market share due to its rapid response time and reliability in applications requiring precise control.

Pneumatic actuators are commonly used in processes such as chemical handling and food processing, where fluctuating conditions demand a robust response mechanism. On the other hand, electric actuator valves are gaining traction, especially in process industries, due to their energy efficiency and ease of integration with digital control systems. Research indicates that the electric actuator market is projected to grow at a CAGR of 6.5% over the next five years, driven by innovations in automation technology.

Hydraulic actuators, while less common, are vital in applications requiring high torque and power. Industries such as oil and gas and heavy manufacturing often rely on hydraulic valves to manage processes under extreme conditions. Understanding these distinctions is crucial for making informed choices that align with operational needs and efficiency goals.

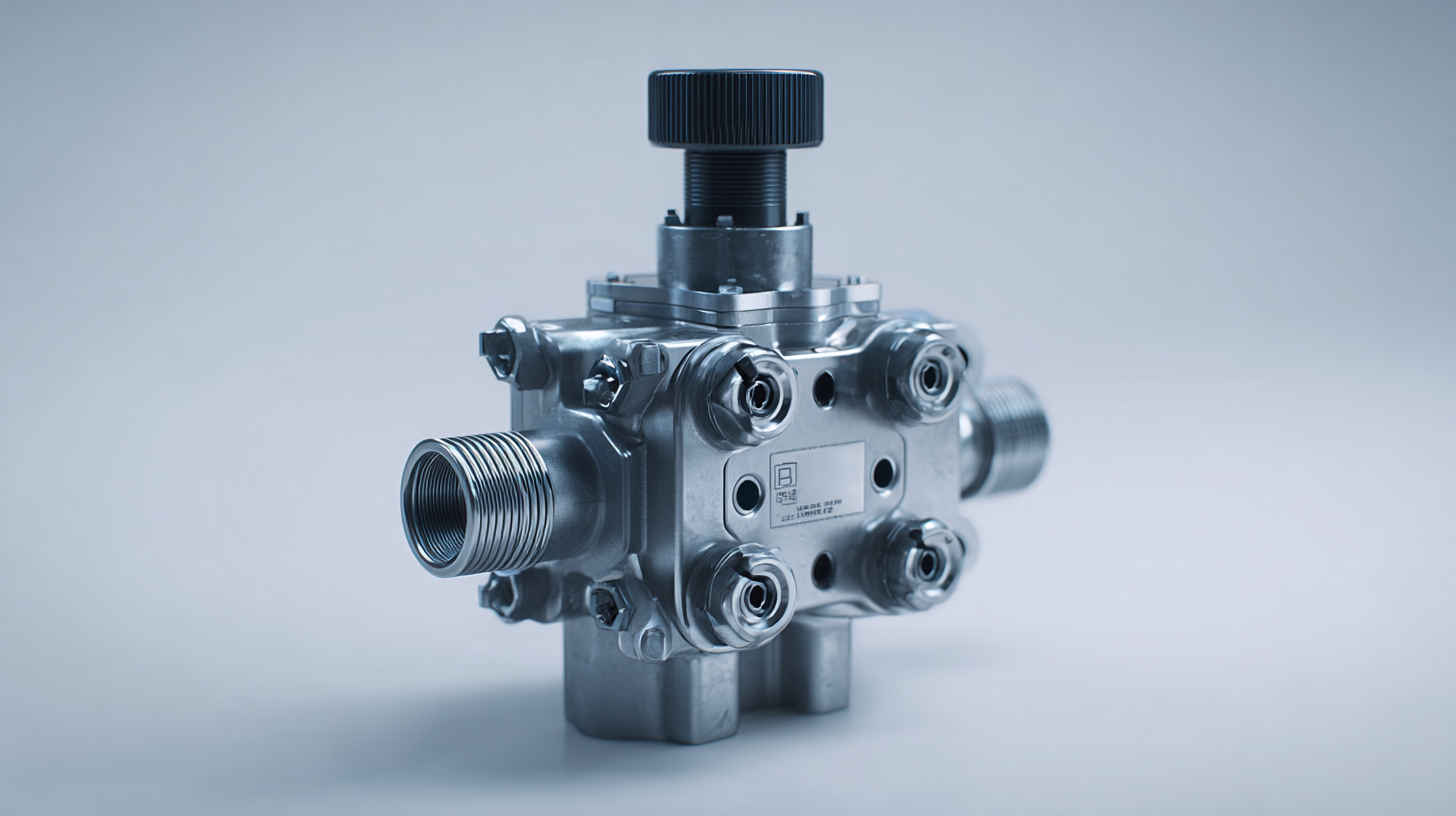

Key Factors to Consider When Selecting an Actuator Valve

When selecting the right actuator valve for industrial applications, several key factors demand careful consideration.

The first is the valve type, which can significantly influence performance and efficiency.

Research from the Valve Manufacturers Association indicates that globe valves typically offer better throttling capabilities,

while ball valves excel in tight sealing. It is vital to match the valve type to the specific requirements of your application,

whether it involves regulating flow or ensuring isolation.

Another critical aspect is the actuator type. Options include electric, pneumatic, and hydraulic actuators, each with unique benefits.

According to a recent market report by Mordor Intelligence, the demand for electric actuators is projected to grow by 8.2% annually through 2026

due to their energy efficiency and precision in control. Additionally, considering environmental factors—such as temperature and humidity—

can help determine the best material and design for the actuator valve, ensuring longevity and reliability in harsh conditions.

By evaluating these factors, industries can enhance their operational efficiency and reduce downtime.

Evaluating Control Options: Electric vs. Pneumatic vs. Hydraulic Actuators

When selecting the right actuator valve for your industrial application, understanding the control options available is vital. Electric actuators are known for their precision and ease of integration with control systems. They are ideal for applications requiring exact position control and can be easily monitored through various digital interfaces. Their low maintenance requirements and energy efficiency make them a popular choice in modern automation systems.

On the other hand, pneumatic actuators offer rapid response times and are typically favored in environments where speed is critical. They operate using compressed air, making them suitable for applications involving frequent cycling. However, they require a constant supply of air and can be affected by temperature fluctuations, which may require additional considerations in certain industrial settings.

Hydraulic actuators provide immense force and are often employed in heavy machinery applications. They excel in situations where high torque is required but might present challenges with leakage or fluid management.

**Tips:** When choosing an actuator, consider the environment of your application—temperature, humidity, and space limitations can impact your choice. Additionally, think about the energy source; electric actuators may save on operational costs, while pneumatic options may offer superior speed. Always assess the total cost of ownership, including maintenance and operation, to make the best decision for your needs.

How to Choose the Right Actuator Valve for Your Industrial Application - Evaluating Control Options: Electric vs. Pneumatic vs. Hydraulic Actuators

| Actuator Type |

Operating Mechanism |

Speed |

Power Source |

Cost |

Maintenance |

| Electric Actuator |

Electric motor drives a screw or gear mechanism. |

Moderate to fast response times. |

Electric power (AC/DC). |

Higher initial cost, but lower operating cost. |

Low maintenance; mostly wear parts. |

| Pneumatic Actuator |

Compressed air or gas drives a piston. |

Fast response times. |

Compressed air. |

Moderate cost; energy usage can vary. |

Moderate maintenance; requires clean air supply. |

| Hydraulic Actuator |

Hydraulic fluid drives a piston. |

Very fast and powerful. |

Hydraulic fluid reservoir or pump. |

Higher cost and complex setup. |

High maintenance; leak management required. |

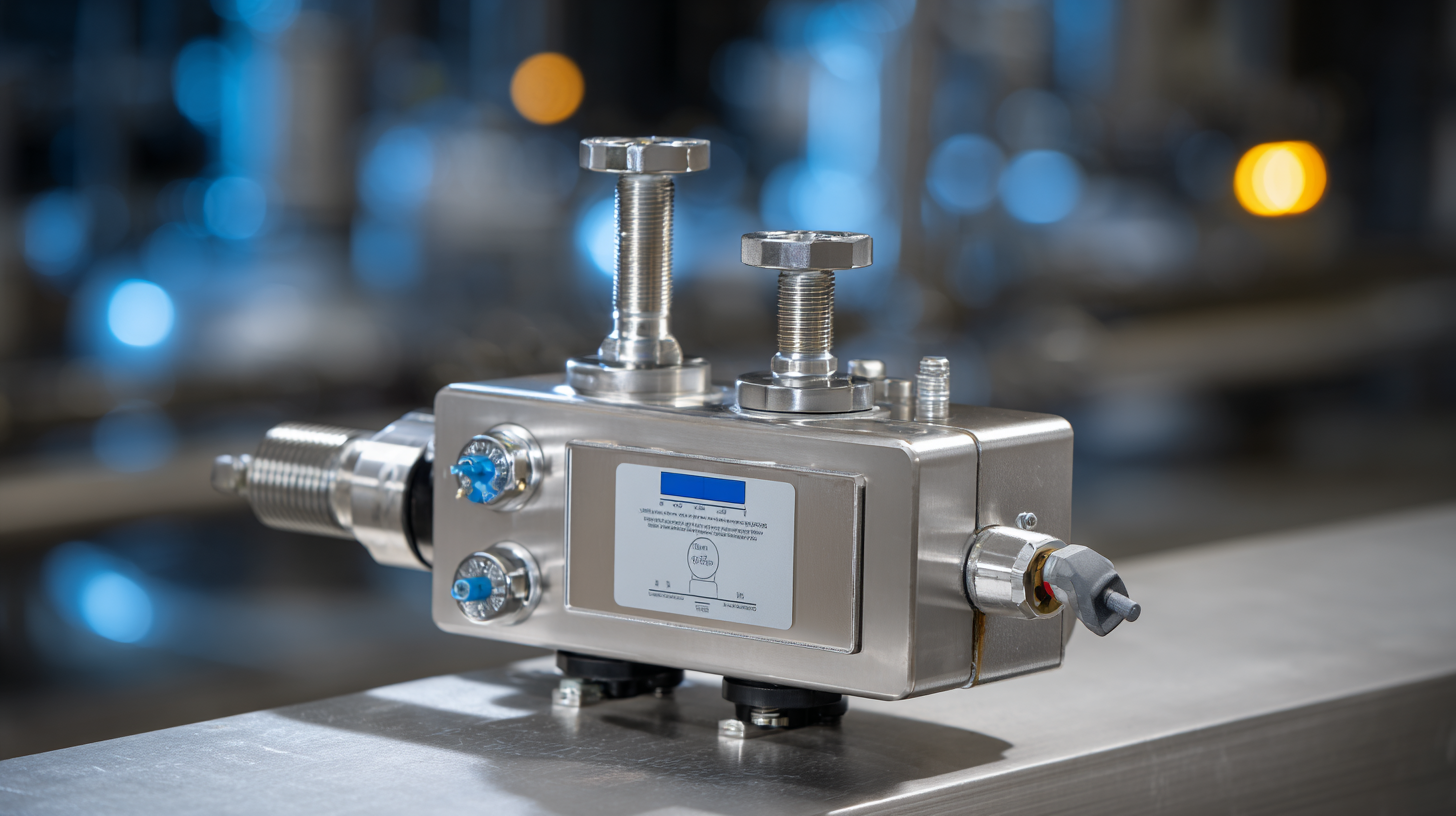

Assessing Compatibility with Existing Systems and Applications

When selecting an actuator valve for industrial applications, assessing compatibility with existing systems is crucial. According to a report by Research and Markets, the global actuator market is expected to reach $32 billion by 2025, highlighting the growing significance of choosing the right components that integrate seamlessly within current infrastructures. Compatibility considerations include evaluating the existing control systems, power supply voltages, and communication protocols to ensure the actuator valve can be effectively integrated without the need for extensive modifications.

Moreover, it's essential to analyze the specific operational requirements of the application, such as pressure ratings and flow characteristics. The Hydraulic Institute's data reveals that around 30% of operational failures in industrial settings can be attributed to poor system compatibility. This statistic underscores the importance of selecting actuator valves that match the specifications of the existing piping systems and machinery, thereby enhancing performance reliability. Conducting a thorough compatibility assessment will not only improve operational efficiency but also extend the lifespan of the overall system, ultimately leading to reduced maintenance costs and downtime in industrial environments.

Actuator Valve Types and Their Compatibility Assessment

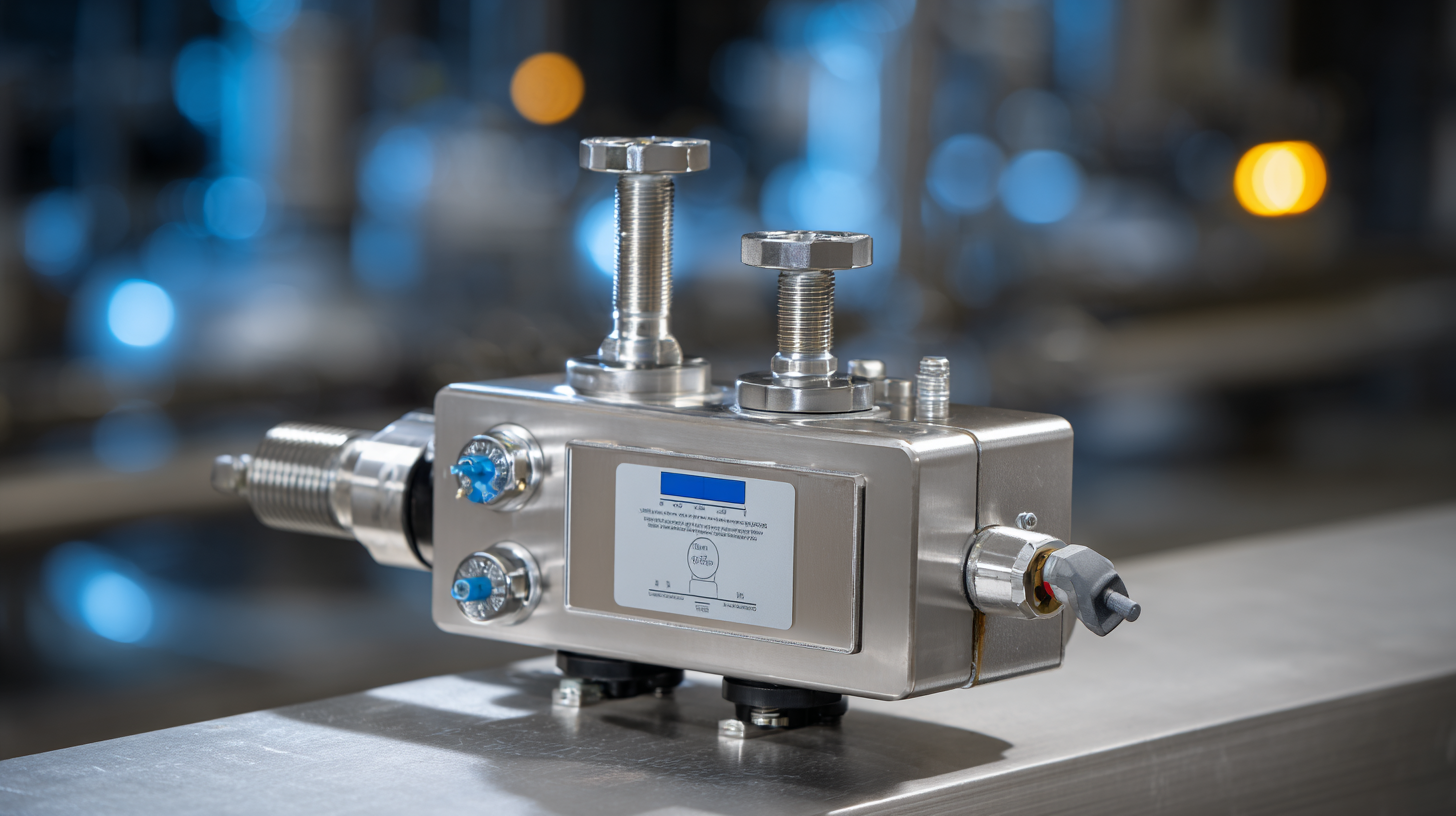

Maintenance and Durability: Choosing the Right Actuator Valve for Longevity

When selecting an actuator valve for industrial applications, maintenance and durability play pivotal roles in ensuring long-term performance. Studies have shown that well-maintained actuator systems can reduce operational costs by up to 30% due to minimized downtime and repair needs. For instance, a recent report highlighted that companies implementing preventive maintenance measures on their actuator systems saw a significant increase in lifespan, often exceeding manufacturer specifications by 20%.

When selecting an actuator valve for industrial applications, maintenance and durability play pivotal roles in ensuring long-term performance. Studies have shown that well-maintained actuator systems can reduce operational costs by up to 30% due to minimized downtime and repair needs. For instance, a recent report highlighted that companies implementing preventive maintenance measures on their actuator systems saw a significant increase in lifespan, often exceeding manufacturer specifications by 20%.

Moreover, the shift from hydraulic to electric actuators is gaining traction due to their enhanced reliability and reduced maintenance requirements. Electric actuators tend to have fewer moving parts, leading to less wear and tear over time. Key steps in this conversion include accurately determining the required load and evaluating the existing infrastructure for compatibility. By investing in durable electric actuators, companies not only enhance their maintenance practices but also contribute to a more sustainable operation, with the potential to lower energy consumption by approximately 15% compared to traditional hydraulic systems.

When selecting an actuator valve for industrial applications,

When selecting an actuator valve for industrial applications,