2025 How to Choose the Right Industrial Diaphragm Valves for Your Needs

Choosing the right industrial diaphragm valves is crucial for the efficiency and reliability of various systems within the industrial sector. These valves play a vital role in controlling the flow of fluids, gases, and slurries, making them an essential component in many applications, including water treatment, chemical processing, and pharmaceuticals. Given their importance, selecting the appropriate diaphragm valves can significantly impact operational performance and safety.

With a multitude of options available on the market, understanding the key factors that influence the selection process is essential for optimizing functionality and ensuring compatibility with system requirements. Considerations such as material compatibility, pressure ratings, and the specific application requirements should guide your decision-making process. As industries continue to evolve, the demand for efficient and reliable fluid control mechanisms, such as industrial diaphragm valves, has never been more pronounced. This article will provide insights into the essential criteria for choosing the right diaphragm valves to meet your unique operational needs effectively.

Understanding the Functionality of Industrial Diaphragm Valves

Industrial diaphragm valves play a crucial role in various applications across different industries by providing precise control over the flow of fluids. The functionality of these valves is inherently tied to their design, which utilizes a flexible diaphragm to regulate the flow path. When the valve actuator is engaged, the diaphragm is distorted, either opening or closing the flow passage. This mechanism not only allows for effective throttling but also minimizes leakage since the diaphragm creates a seal that prevents fluids from escaping, making it ideal for handling corrosive or abrasive materials.

In addition to their sealing capabilities, industrial diaphragm valves offer advantages in terms of hygiene and ease of maintenance. The absence of moving parts in direct contact with the fluid stream reduces the risk of contamination, a feature that is particularly beneficial in industries like pharmaceuticals and food processing. Moreover, because the diaphragm can be replaced without removing the entire valve assembly from the piping system, maintenance becomes straightforward. Understanding these functionalities helps industries choose the right diaphragm valves tailored to their specific needs, ensuring reliability and efficiency in their operations.

Key Factors to Consider When Selecting Diaphragm Valves

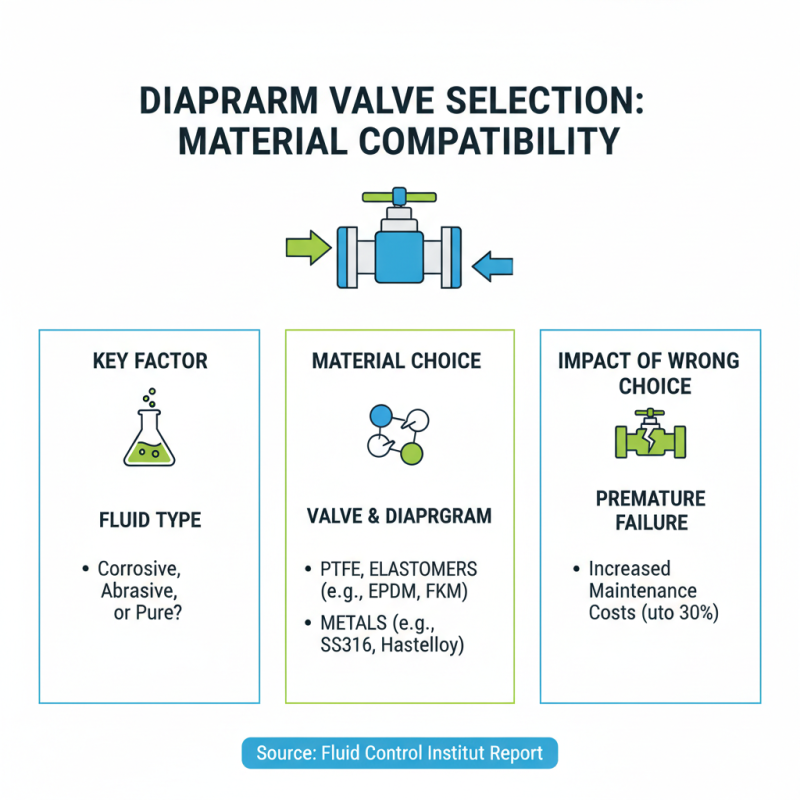

When selecting diaphragm valves for industrial applications, several key factors play a pivotal role in ensuring optimal performance and reliability. One essential factor is the valve's material compatibility. Different media can corrode or degrade materials differently; for instance, corrosive fluids require valves made from resilient materials like PTFE or elastomers. According to a report from the Fluid Control Institute, improper material choices can lead to premature valve failure, increasing maintenance costs by up to 30%.

Another crucial consideration is the valve's pressure and temperature ratings. Diaphragm valves are typically suited for specific pressure ranges; exceeding these limits can compromise the integrity of the valve. A detailed analysis from the American Society of Mechanical Engineers emphasizes that understanding the operational environment can significantly enhance the longevity of valve systems, potentially reducing replacement intervals by several years.

Tips: When selecting diaphragm valves, always evaluate the application requirements meticulously. Consult performance data and ensure that the diaphragm type aligns with both the media characteristics and the operational parameters. Additionally, prioritize suppliers that provide comprehensive testing certifications, as this translates to greater assurance regarding the product's reliability.

Furthermore, the flow characteristics of diaphragm valves should also align with the system's demands. While on-off control is a common application, many industries require flow regulation capabilities. Given that approximately 70% of industrial applications utilize some form of flow control, confirming that the valve can achieve the required flow coefficient (Cv) is vital to system efficiency.

Material Compatibility: Choosing the Right Valve for Your Application

Choosing the right industrial diaphragm valves requires a thorough understanding of material compatibility for optimal performance in specific applications. Each industrial process can expose valves to various chemicals and operational conditions, making it essential to select materials that can withstand these factors without compromising integrity. According to a recent industry report, more than 30% of valve failures are attributed to improper material selection, highlighting the critical nature of this decision.

When evaluating materials, one must consider factors such as corrosion resistance, temperature tolerance, and chemical compatibility. For instance, PTFE (polytetrafluoroethylene) is widely favored for its excellent chemical resistance across a broad pH range, making it suitable for both acidic and caustic environments. In contrast, elastomers like EPDM (ethylene propylene diene monomer) provide flexibility and durability in water applications but may not perform well in hydrocarbon environments. According to a study published in the Journal of Fluid Engineering, selecting the wrong material can lead to a significant decrease in operational efficiency and increase maintenance costs by up to 25% over the lifecycle of the equipment.

Moreover, the selection process is further complicated by varying industry standards that dictate material guidelines for specific applications, especially in sectors such as pharmaceuticals and food processing. Regulatory bodies often mandate compatibility with certain materials to ensure safety and efficacy, thus requiring professionals to stay informed about changing standards and advancements in material science. This diligence not only enhances the reliability of the diaphragm valves but also optimizes operational efficiency and cost-effectiveness in the long run.

Assessing Pressure and Temperature Ratings of Diaphragm Valves

When selecting the right industrial diaphragm valves, the pressure and temperature ratings are critical factors that need careful consideration. Diaphragm valves are designed to handle a range of pressures and temperatures, and understanding these ratings is essential for ensuring optimal performance and longevity. Typically, these valves are available in various materials and designs that can withstand specific conditions, making it important to match the valve’s specifications with your operational requirements.

**Tips:** Always check the manufacturer’s specifications for pressure and temperature ratings. Consider the maximum and minimum levels your application may reach over time, as exceeding these ratings could lead to premature failure. Additionally, ensure compatibility with the medium being controlled to maintain efficiency and avoid any potential issues.

Accurate assessment of the operating conditions will guide you in choosing the right diaphragm valve. For instance, high-pressure applications may require reinforced diaphragm materials, while media with extreme temperatures may necessitate special seals or body materials. Analyzing these aspects not only contributes to the longevity of the valve but also enhances the safety of the entire system.

**Tips:** It can be beneficial to consult with industry experts or guidelines for selecting membranes that can handle specific temperature extremes. Always conduct tests in your operational environment when feasible, to ensure that the valve performs as expected under actual conditions.

Maintenance and Longevity Considerations for Diaphragm Valves

When selecting industrial diaphragm valves, understanding the maintenance and longevity considerations is critical for ensuring optimal performance in various applications. Regular maintenance not only prolongs the lifespan of diaphragm valves but also minimizes the risk of operational failures. According to a recent industry report, improper maintenance can lead to a 30% increase in valve failure rates, resulting in costly downtime and repairs. Implementing a routine inspection schedule can help detect early signs of wear and facilitate timely interventions.

To enhance the longevity of diaphragm valves, it's essential to consider the materials used in their construction. High-quality elastomers, for example, can significantly improve resistance to corrosion and wear, extending the operational life of the valve. Additionally, proper installation and alignment play a pivotal role; misalignment can lead to uneven wear and increased maintenance requirements. A study by the American Society of Mechanical Engineers highlights that valves with proper alignment can last up to 50% longer than those that are not correctly installed.

Tips: Regularly clean and lubricate diaphragm valves to reduce friction and wear. Establish a preventive maintenance program that includes checking for leaks, ensuring proper actuator operation, and monitoring system pressures. This proactive approach can help ensure that diaphragm valves operate efficiently and safely throughout their intended lifespan.