Selecting the right Grooving Machine for your shop is a critical decision that can impact both productivity and output quality. According to the latest industry reports, the global grooving machine market is projected to grow at a CAGR of 5.6% over the next five years, highlighting the increasing demand for specialized machining solutions in various sectors, including automotive and aerospace. With diverse types of grooving machines available—each designed for specific applications and materials—shop owners must carefully assess their unique needs to avoid common pitfalls and maximize efficiency. Understanding the features, capabilities, and limitations of different models can mean the difference between a successful operation and costly production delays. This blog aims to guide you through the key considerations to ensure you choose the best Grooving Machine tailored to your shop requirements.

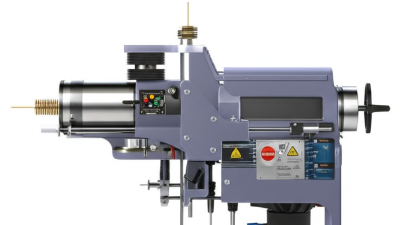

When it comes to selecting the right grooving machine for your shop, understanding the different types available is crucial. These machines typically fall into categories such as vertical, horizontal, and CNC grooving machines. Vertical grooving machines are ideal for creating grooves in thick materials, while horizontal models excel in high-precision work for thinner materials. CNC grooving machines offer enhanced versatility, allowing for intricate designs and automated processes, making them perfect for large production runs.

To ensure you choose the best machine for your needs, consider your specific applications. For instance, if your projects often involve various materials and intricate patterns, a CNC grooving machine may be your best option. On the other hand, if you primarily work with thicker materials, a vertical grooving machine might be more suitable.

Tip: Always evaluate the material types you work with and the size of grooves you need to create. This analysis will guide you in selecting a machine that meets both your operational capabilities and production goals. Additionally, factor in the available space in your workshop and the machine's ease of use, as these aspects can significantly influence your daily operations.

| Type of Grooving Machine | Applications | Material Compatibility | Typical Features |

|---|---|---|---|

| Manual Grooving Machine | Small-scale production, hobbyist projects | Wood, plastics | Compact design, manual load/unload |

| Semi-Automatic Grooving Machine | Medium-scale production, furniture manufacturing | Wood, laminated surfaces | Automatic feed, adjustable cutting depth |

| Fully Automatic Grooving Machine | High-volume production, industrial applications | Wood, MDF, particleboard | CNC controlled, high precision, multi-tool capability |

| Portable Grooving Machine | On-site work, repairs | Wood, light metals | Lightweight, battery-operated |

| Vertical Grooving Machine | Cabinet making, decorative woodwork | Wood, veneer | Vertical cutting, tilting table |

When selecting a grooving machine for your shop, several key features should be considered to ensure it meets your specific needs. One of the most crucial aspects is the machine’s versatility. Look for a model that can handle various materials and thicknesses. This flexibility will allow you to accommodate different projects without needing multiple machines, saving both space and money.

Another essential feature is the machine's precision. High-quality grooving machines should have adjustable settings that facilitate accurate cuts. Consider models equipped with digital controls or laser guides, as they can significantly enhance your cutting precision, resulting in cleaner grooves and reduced waste.

Tip: Always assess the machine's ease of use. A user-friendly interface can streamline operations, reduce training time for new employees, and increase overall productivity. Additionally, check for the availability of customer support and replacement parts; this can make a significant difference in maintenance and longevity. By keeping these features in mind, you can select the right grooving machine that aligns with your shop's requirements.

When considering the ideal grooving machine for your workshop, understanding the differences between manual and automatic models is crucial. According to a report from the Machinery Research Institute, manual grooving machines can be a cost-effective solution for small-scale operations. They generally have lower initial costs, with prices varying from $1,000 to $5,000. However, operators can typically only produce 60-70 grooves per hour, making them less efficient for larger projects.

In contrast, automatic grooving machines have seen a significant rise in popularity due to their efficiency and precision. The Automated Manufacturing Association reports that these machines can produce an impressive 150-300 grooves per hour, depending on the model. Although their upfront cost ranges from $10,000 to $50,000, the long-term savings in labor costs and enhanced productivity often justify this investment for larger shops. Furthermore, with advancements in technology, automatic machines now often come equipped with features such as programmable settings and real-time monitoring, allowing for improved accuracy and reduced waste. As businesses aim to maximize output while minimizing operational costs, the choice between manual and automatic grooving machines becomes a pivotal decision in optimizing workshop performance.

When selecting a grooving machine for your shop, it’s crucial to consider the long-term cost-effectiveness of your investment. A comprehensive review of cost-benefit analyses highlights that businesses often underestimate the operational expenses associated with their tools.

According to industry reports, a well-selected grooving machine can lead to a cost reduction of up to 30% over its lifecycle by enhancing productivity and reducing waste.

Additionally, sustainable machining practices have been gaining traction, with evidence showing that implementing energy-efficient equipment can result in significant savings on energy costs—up to 40%, as noted in recent studies.

By investing in machines designed with sustainability in mind, shops can not only cut operational costs but also make strides towards environmental responsibility, aligning with broader industry goals for reducing the carbon footprint.

In essence, the right grooving machine isn't just an expense; it's a strategic investment that can lead to substantial long-term financial benefits and a more sustainable operation.

Maintaining your grooving machine is essential to ensure its longevity and optimal performance. One of the first steps in maintenance is regular cleaning. Dust, debris, and metal shavings can accumulate and hinder the machine's function. After each use, take the time to wipe down surfaces and ensure that the inner mechanisms are free from contaminants. Additionally, lubricating moving parts regularly will minimize friction and wear, allowing your machine to operate smoothly.

Another crucial aspect of maintenance is conducting routine inspections. Check for wear and tear on components such as blades and belts, as well as any signs of rust or corrosion. Addressing minor issues before they escalate can save you significant time and money in repairs. Furthermore, following the manufacturer's guidelines for maintenance intervals will help you stay on track and maintain warranty coverage. By integrating these practices into your shop routine, you'll maximize the lifespan of your grooving machine and enhance overall productivity.