How to Choose the Right Body Valve for Your Needs?

Choosing the right body valve is crucial for any system. Each application has unique requirements. As industry expert John Smith once stated, "Selecting the right valve can make or break your system's efficiency." This insight highlights the importance of careful consideration in valve selection.

Body valves come in various types, sizes, and materials. You'll find options like ball valves, gate valves, and butterfly valves. Understanding their functions is vital. Each type offers distinct advantages. A ball valve might provide quick shut-off, while a gate valve is ideal for flow control. However, every choice has potential drawbacks. Consider maintenance issues or installation concerns.

For many, the decision process can be overwhelming. Not all valves will suit every scenario. It's essential to evaluate your specific needs. Pay attention to pressure ratings and flow requirements. Sometimes, the most popular choice may not be the best one. Reflecting on these factors will lead to a more informed selection of the right body valve.

Understanding Different Types of Body Valves

When selecting a body valve, understanding different types is crucial. Body valves come in various forms, each serving specific applications. You might encounter ball valves, gate valves, and butterfly valves. Each type has distinct advantages and disadvantages. For instance, ball valves provide excellent sealing, making them suitable for shut-off applications. Gate valves, on the other hand, are ideal for full flow but can be less effective for throttling.

Consider how your valve will be used. For high-pressure systems, reliability is paramount. You don’t want a valve that may fail under stress. Think about maintenance as well. Some valves require more frequent checks than others. This could be a hassle.

Tip: Always check the valve material. It should match the fluid type to prevent corrosion.

While researching, don’t overlook the sizing. A valve that's too small can lead to pressure drops. On the contrary, an oversized valve might not perform efficiently. It's about finding the right balance.

Tip: Consult experts if you're unsure. They can provide insights tailored to your needs. This can save you time and money in the long run. Remember, the right choice enhances system performance.

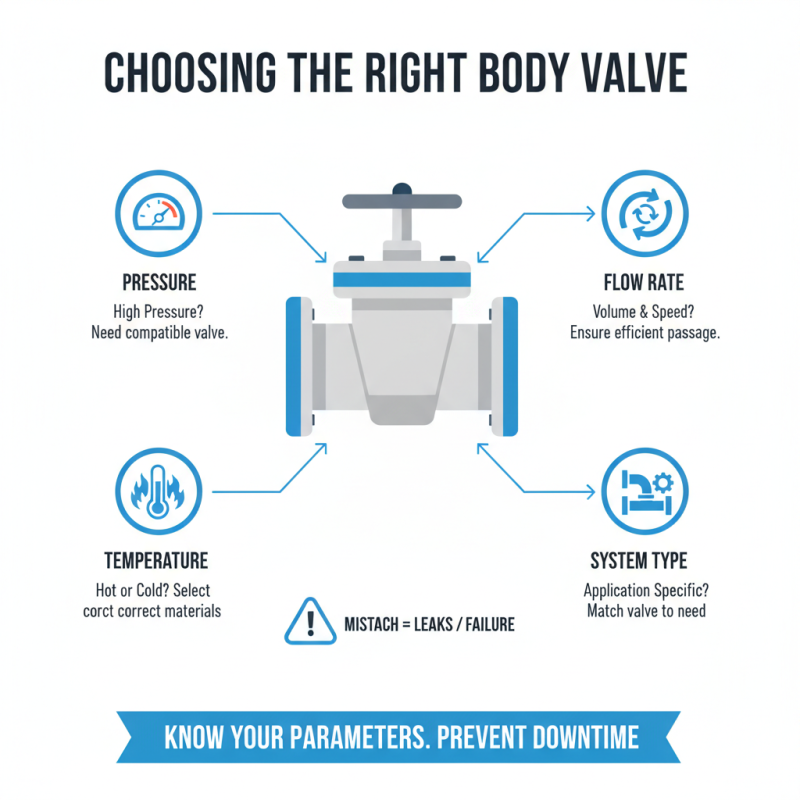

Assessing Your System Requirements and Specifications

Choosing the right body valve starts with understanding your specific system requirements. Different systems have various pressure levels, flow rates, and temperature ranges. Knowing these parameters is vital. For instance, if your system operates under high pressure, you need a valve that can handle it efficiently. A mismatch could lead to leaks or even system failure.

Consider the material as well. Does your application involve corrosive fluids? If so, the valve’s material must resist degradation. The size of the valve is also crucial; it should match the piping system. Too small can restrict flow, while too large may cause turbulence.

Evaluating specifications can be daunting. Make a list of key features required for your setup. Consult with engineers or reference materials for insights. You might find that common choices don’t fit well in your scenario. Sometimes, you need a custom solution. Reflect on your findings. Skip past the popular choices and focus on what truly meets your needs.

Evaluating Material Compatibility for Body Valves

When selecting a body valve, material compatibility is crucial. Different materials react differently under various conditions. For instance, metals may corrode in acidic environments, while plastics can degrade under UV exposure. Identifying the materials that will be in contact with the valve helps ensure long-term performance.

Tips: Consider the fluid's temperature and pressure. Some materials withstand high temperatures better than others. Valves in high-pressure systems need robust materials to prevent failures.

Evaluating environmental factors is essential too. If the valve operates outdoors, weather resistance becomes a priority. Harsh chemicals might require specialized coatings. The right choice avoids leaks and malfunctions.

Tips: Always check for compatibility charts. Manufacturers often provide these for their products. Consult experts when uncertain—they can guide you through intricate selections. A small oversight can lead to costly repairs down the line.

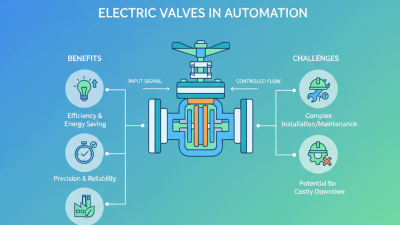

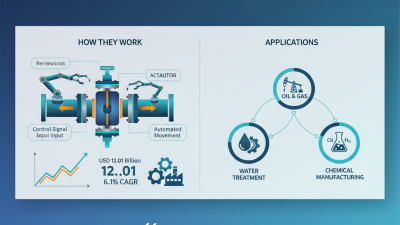

Considering Valve Actuation Methods and Control Options

Choosing the right valve for your application is crucial. One major factor is the actuation method. Actuators can be electric, pneumatic, or hydraulic. Each type has its benefits and drawbacks. Electric actuators are precise and easy to control but can struggle in harsh environments. Pneumatic actuators respond quickly and are often more reliable but can be noisy. Hydraulics offer strong force but require more maintenance and space.

Control options also play a vital role. Manual valves might suffice for simple applications. However, if automation is required, consider smart control systems. These systems offer enhanced monitoring and adjustments. Integration with existing infrastructure can be complex, requiring careful planning. It might not always be easy to switch actuators or control options later on.

It’s important to assess the specific needs of your application. Sometimes, the perfect valve is not the most expensive or complex one. Factors like fluid type, pressure, and temperature matter. Don’t overlook maintenance and installation costs either. The right choice requires thoughtful consideration and, sometimes, trial and error. Ensure you are making informed decisions through research and consultation with professionals.

Body Valve Types and Their Adoption Rates

This bar chart represents the adoption rates of different types of body valves used across various industries. Ball valves lead in popularity, followed by gate valves and globe valves, reflecting their utility and ease of use in multiple applications.

Analyzing Performance Factors: Pressure, Temperature, and Flow Rate

When selecting a body valve, performance factors are crucial. Pressure plays a significant role in valve choice. Different applications demand different pressure ratings. High-pressure systems require valves designed to handle extreme conditions. Look for valves that can withstand these pressures without leaking or failing.

Temperature is another vital consideration. Valves must operate effectively across various temperature ranges. Materials affect performance in extreme heat or cold. For instance, choosing the wrong material can lead to brittleness or deformation. Always check the temperature ratings before making a decision.

Flow rate is equally important. It determines how much fluid passes through the valve. Too high of a flow rate can cause erosion. Too low may impact the system's efficiency. Balancing flow rate with pressure and temperature ensures optimal performance. Remember, each application is unique. Take the time to analyze your needs thoroughly before making a choice. Your long-term success depends on it.