2025 How to Choose the Right Diaphragm Valve for Your System

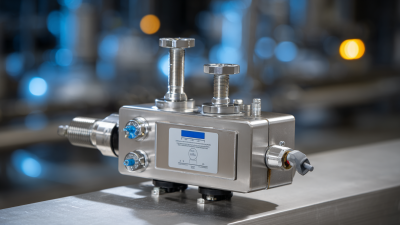

In the ever-evolving world of industrial process control, selecting the right diaphragm valve is crucial for optimizing system performance. According to industry expert Dr. Samuel W. Mitchell, "The right diaphragm valve can not only improve efficiency but also enhance the longevity of your entire system." As companies strive for greater reliability and precision in their operations, understanding the nuances of diaphragm valve selection has become more important than ever.

Diaphragm valves, known for their ability to handle corrosive fluids and maintain system integrity, come in various designs and materials, which can make the selection process daunting. With the right approach and knowledge, however, any operator can navigate this complexity effectively. In this article, we will explore essential factors to consider when choosing a diaphragm valve for your specific application, ensuring that your system operates at its best while aligning with industrial standards and safety regulations.

Understanding Diaphragm Valves: Types and Applications

Diaphragm valves are essential components in various industrial applications due to their ability to provide reliable control of fluid flow. Understanding the types of diaphragm valves and their specific applications is crucial for selecting the right valve for your system. Generally, diaphragm valves are categorized into several types, including

weir-type and

straight-through valves, each with distinct advantages depending on the nature of the fluid being handled. Weir-type valves are often preferred for slurries and viscous fluids due to their design, which minimizes stagnation areas, while straight-through valves are favored for clean, low-viscosity flows.

The diaphragm valve market itself is influenced by growing trends in industries such as pharmaceuticals, food and beverage, and wastewater treatment. According to recent data, the global diaphragm valve market is projected to expand significantly due to increasing automation in these sectors, coupled with a rising focus on sustainability. In particular, the basic chemicals industry, known for its high energy consumption, is seeking more efficient valve solutions that align with decarbonization strategies. This evolving landscape highlights the importance of understanding diaphragm valve types and applications to ensure optimal performance and compliance with industry standards.

Key Factors in Selecting Diaphragm Valves for Your System

When selecting diaphragm valves for your system, several key factors must be carefully considered to ensure optimal performance and compatibility. First and foremost, the application environment plays a critical role. Understanding the nature of the fluid being handled—its viscosity, corrosiveness, and temperature—is essential, as different diaphragm materials offer varying degrees of resistance to these factors. For instance, PTFE diaphragms may be ideal for aggressive chemicals, while rubber may suffice for less corrosive substances.

Another significant aspect to evaluate is the valve size and connection type. Proper sizing helps maintain system pressure and flow rate, preventing issues such as cavitation or excessive turbulence. Additionally, compatibility with existing piping systems is crucial; thus, valve connection types should match or easily adapt to your infrastructure. Lastly, consider the actuation method—manual, pneumatic, or electric—as this choice affects control precision and operational efficiency. By thoroughly assessing these elements, you can make an informed decision that ensures the diaphragm valve you select enhances the performance and reliability of your system.

Key Factors in Selecting Diaphragm Valves for Your System

This chart illustrates the importance of various factors in selecting diaphragm valves for different systems. The data points represent the percentage of users prioritizing each factor based on a survey conducted in the industry.

Material Considerations for Diaphragm Valve Selection

When selecting a diaphragm valve for your system, material considerations play a crucial role in ensuring optimal performance and longevity. The choice of material can significantly affect the valve’s compatibility with different fluids, temperature ranges, and pressure conditions. According to a report from the Fluid Control Institute, over 30% of valve failures can be attributed to improper material selection, underscoring the importance of doing thorough research.

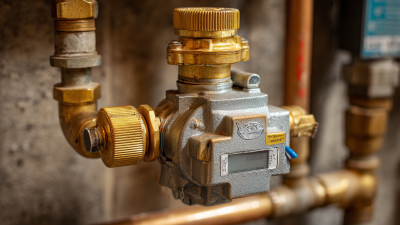

One key factor to consider is the chemical compatibility of the diaphragm material with the fluid being handled. For instance, EPDM and PTFE (Teflon) are popular choices for aggressive chemicals, while nitrile rubber may suffice for water or oil applications. Furthermore, the operating temperature and pressure should also influence your material choice. Materials like stainless steel and brass are recommended for high-pressure scenarios, whereas plastic options are more suitable for lower pressure and corrosive conditions.

Tips:

When in doubt, refer to the manufacturer’s material compatibility charts to avoid costly mistakes. Always consult an industry expert or a material specialist if your application involves unique chemicals or extreme conditions. Lastly, consider environmental factors, such as exposure to UV light or moisture, which can degrade certain materials over time.

Sizing and Pressure Ratings of Diaphragm Valves

When selecting a diaphragm valve for your system, understanding the sizing and pressure ratings is crucial to ensure optimal performance and reliability. The size of the diaphragm valve affects not only the flow rate but also the pressure drop within the system. Typically, diaphragm valves are available in various sizes, ranging from small units suitable for low flow applications to larger valves needed for significant flow demands. When sizing the valve, consider the connections to existing piping and the overall layout of the system to ensure a proper fit and efficient operation.

Pressure ratings are equally important when choosing a diaphragm valve. Each valve is rated to handle specific pressure limits, which can vary significantly based on the material of the valve body and diaphragm. For instance, thermoplastic diaphragm valves may have lower pressure ratings compared to those made from stainless steel or other metals. It is essential to consult the manufacturer’s specifications to ascertain that the selected valve meets or exceeds the pressure requirements of your application. Additionally, understanding the operating conditions, such as temperature and the kind of medium flowing through the valve, will guide you in selecting a valve that guarantees safety and performance over time.

2025 How to Choose the Right Diaphragm Valve for Your System - Sizing and Pressure Ratings of Diaphragm Valves

| Size (Inches) |

Pressure Rating (PSI) |

Body Material |

Diaphragm Material |

Application |

| 1 |

150 |

PVC |

EPDM |

Water Treatment |

| 1.5 |

200 |

PP |

NBR |

Chemical Processing |

| 2 |

300 |

Stainless Steel |

PTFE |

Pharmaceuticals |

| 3 |

150 |

Cast Iron |

EPDM |

Wastewater Management |

| 4 |

150 |

Aluminum |

Silicone |

Food Processing |

Maintenance Tips for Optimal Diaphragm Valve Performance

To ensure optimal performance of diaphragm valves, regular maintenance is essential. One of the first steps involves routine inspections to check for any signs of wear or damage. Look for cracks or deformations in the diaphragm, as these can lead to leaks or performance issues. It is advisable to establish a maintenance schedule that aligns with the valve's application conditions, as more demanding environments may require more frequent checks.

Another critical aspect of maintenance is the lubrication of moving parts. Proper lubrication helps in minimizing friction and wear between components, promoting smoother operation. It's important to use the appropriate lubricant recommended by manufacturers, as some valves operate in sensitive environments where the wrong lubricant could lead to complications. Additionally, always ensure that the valve is cleaned regularly to eliminate any buildup of debris or contaminants that could affect its functionality. By adhering to these maintenance tips, you can extend the lifespan of diaphragm valves and maintain their efficiency within your system.