How to Choose the Right Straight Valves for Your Project?

Choosing the right straight valves for your project is crucial. Experts emphasize this importance in various industries. John Smith, a leading valve engineer, once remarked, "The correct valve choice can make or break your project."

Straight valves are essential in numerous applications. They control flow effectively, ensuring optimal performance. However, not all straight valves are the same. Each type serves a specific purpose and material choice matters significantly. Consider environments where the valves will be used. For instance, corrosive substances require special materials.

When selecting straight valves, pay attention to details. Pressure ratings, end connections, and operational temperature are key factors. Missteps in valve selection may lead to inefficiencies. This can result in increased costs and delayed projects. Before making a final decision, reflect on your project's specific needs. Each choice should align with your operational goals.

Understanding the Various Types of Straight Valves Available

When selecting straight valves, understanding the various types available is crucial. Straight valves come in several designs, including gate, globe, and ball valves. Each type serves specific purposes, impacting efficiency and cost. For example, a recent industry report shows that gate valves are preferred for on/off applications, while globe valves are often chosen for throttling services.

Gate valves account for approximately 40% of the market share in the valve industry, according to a 2021 study. This popularity arises from their ability to provide a straight flow path with minimal pressure drop. In contrast, ball valves, with a market share of around 25%, function well for quick shut-off services. However, they may not be suitable for flow regulation. A critical aspect to consider is that while globe valves excel at throttling, they incur higher pressure losses.

It's vital to assess the specific requirements of your project. Each valve type has unique characteristics, which can lead to mistakes if overlooked. For instance, using a globe valve for a high-capacity quick shut-off could result in inefficiency. Analyzing your system’s flow characteristics and temperature will guide you in selecting the right straight valve type, avoiding costly misunderstandings.

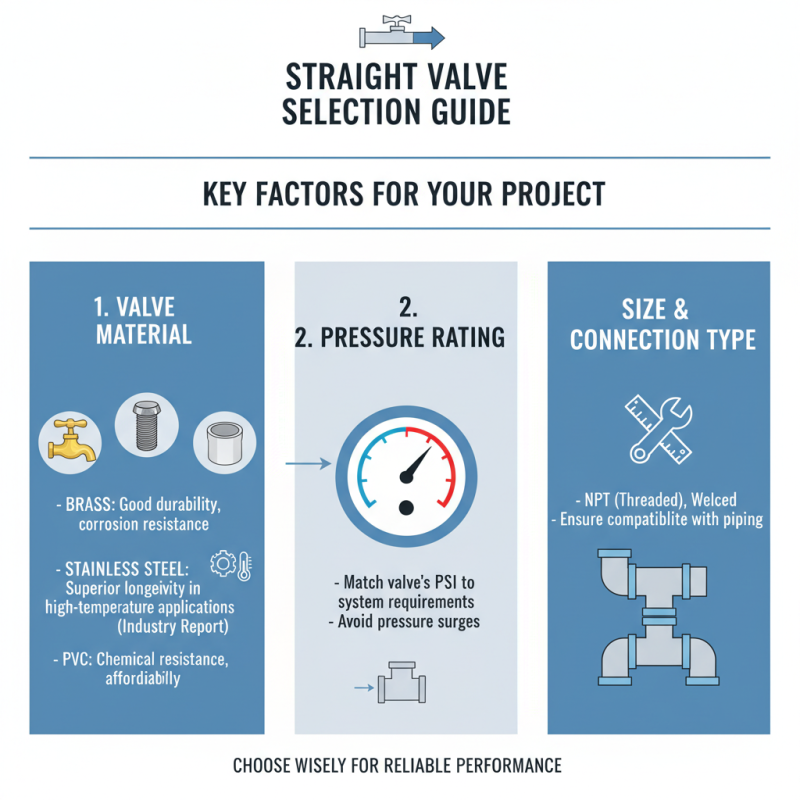

Key Factors to Consider When Selecting Straight Valves for Your Project

When selecting straight valves for your project, several key factors must be considered. The first factor is the valve’s material. Different materials, such as brass, stainless steel, and PVC, offer varying levels of durability and corrosion resistance. According to industry reports, stainless steel valves provide superior longevity in high-temperature applications, reducing the need for frequent replacements.

Another critical aspect is the valve’s pressure rating. The American Society of Mechanical Engineers (ASME) suggests that choosing a valve with a higher pressure rating than required is prudent. This provides a safety margin and ensures reliability during operation. On average, failing to assess the appropriate pressure rating can lead to costly failures, with potential downtime exceeding $50,000 a day.

Flow characteristics should not be overlooked either. Straight valves often have low resistance, allowing for better flow rates. However, the design must match the system requirements. Interestingly, studies reveal that mismatched valves can reduce overall system efficiency by up to 20%. Neglecting this can lead to increased operational costs and reduced performance. Thus, careful consideration in choosing straight valves is essential for project success.

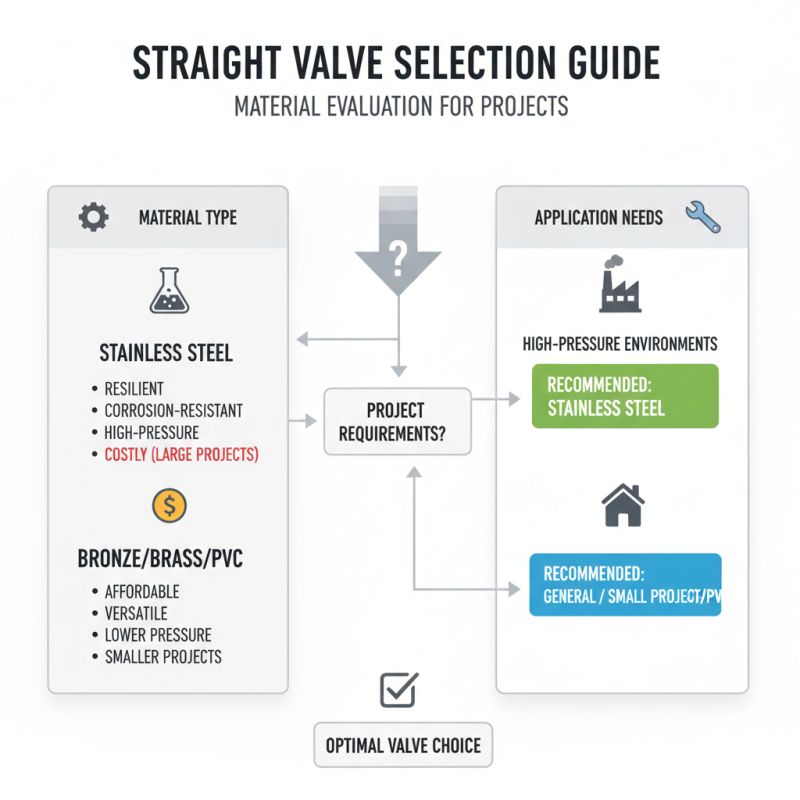

Evaluating Valve Materials and Their Suitability for Different Applications

Selecting the right straight valve for your project involves careful evaluation of materials. Different applications demand various characteristics. For instance, stainless steel is resilient and resistant to corrosion. It suits high-pressure environments. However, it can be cost-prohibitive for small projects.

In contrast, PVC valves are lightweight and affordable. They work well in chemical applications but may not withstand high temperatures. If your project involves water supply, brass could be a better choice. It provides excellent strength but can corrode in certain conditions. This choice requires careful consideration of the environment where the valve will be used.

It's also crucial to consider the seal and gasket materials. EPDM or Viton can affect the valve's lifetime. Sometimes, standard options may not fit perfectly. You might find you need something customized. Understanding these details can save time and resources in the long run. Always weigh the trade-offs when making a choice.

Important Specifications and Standards for Straight Valves

When selecting straight valves, understanding key specifications is essential. These specifications dictate how effectively the valve will perform in your project. One crucial aspect is the valve's material. The choice of material affects durability and compatibility with fluids. Common materials include stainless steel, brass, and plastics. Each has its pros and cons. Consider the operating temperature and pressure too. Many overlook this aspect, but it significantly impacts valve selection.

Another vital standard is the valve's size. It's important to ensure that the valve matches your piping system. A mismatch can lead to leaks or inefficient flow. Pay attention to the flow rate specifications. This information helps determine if the valve can handle the required volume. Additionally, check for an appropriate pressure rating. Some valves may not withstand high-pressure conditions.

Always review the standards governing the valves. Industry standards ensure safety and reliability. Compliance with these standards may vary between regions, which adds complexity. Do not ignore certification marks and compliance documents. Missing these can lead to costly mistakes. Choosing the right straight valves requires careful thought and review.

Common Mistakes to Avoid When Choosing Straight Valves

Choosing the right straight valves for your project can be challenging. One common mistake is overlooking the pressure rating. According to industry standards, valves should match the system's operating pressure. Using valves with inadequate pressure ratings can lead to leaks or failures.

Another frequent error is ignoring the material compatibility. Different fluids react differently with materials. For instance, using a valve made of brass in a corrosive environment can quickly deteriorate. A report from the Fluid Control Association noted that material failure accounts for 30% of valve-related issues.

Additionally, many people underestimate the importance of size. A valve that is too small will restrict flow, causing inefficiencies. Conversely, an oversized valve can lead to turbulence and increased wear. Take time to analyze flow rates and system requirements before making a choice. Remember, what seems easier might complicate your project down the line.

How to Choose the Right Straight Valves for Your Project? - Common Mistakes to Avoid When Choosing Straight Valves

| Dimension |

Material |

Pressure Rating |

Temperature Range |

Common Applications |

| 1/2 inch |

Brass |

150 PSI |

-20°C to 80°C |

Water, Air |

| 3/4 inch |

Stainless Steel |

300 PSI |

-50°C to 150°C |

Oil, Gas |

| 1 inch |

PVC |

100 PSI |

0°C to 60°C |

Chemicals, Water |

| 2 inch |

Ductile Iron |

250 PSI |

-10°C to 90°C |

Fire Protection, Water |

| 3 inch |

Aluminum |

200 PSI |

-40°C to 120°C |

Air, Water |