Understanding Electric Valves and Their Applications?

Electric valves play a crucial role in numerous industries. These devices automate the flow of liquids and gases. Understanding their design and function is essential for effective application.

The electric valve operates by converting electrical energy into mechanical motion. This energy controls the opening and closing of the valve. In industrial settings, they ensure efficiency and safety in system management. However, improper installation can lead to issues. For instance, a misaligned electric valve may cause leaks or malfunctions.

These valves are present in applications like automation systems, irrigation, and HVAC. Their versatility and precision make them invaluable. Yet, users must consider potential challenges, such as power loss. Regular maintenance is vital to mitigate these risks. Recognizing both benefits and limitations aids in making informed decisions.

What Are Electric Valves?

Electric valves are essential components in various industries. They control the flow of liquids and gases. Using electrical signals, these valves open or close precisely. This automation brings efficiency and accuracy.

In different sectors, electric valves find various applications. They are crucial in water treatment plants, chemical processing, and HVAC systems. Different environments require specific designs of electric valves. This diversity can lead to mistakes if not chosen wisely. Each application may demand unique considerations.

Understanding the specific needs of your system is vital. Electric valves must be compatible with the medium flowing through them. For instance, corrosive fluids may require special materials. This highlights the importance of thorough research. Users should weigh efficiency against maintenance needs. The balance is crucial for long-term performance.

Types of Electric Valves and Their Mechanisms

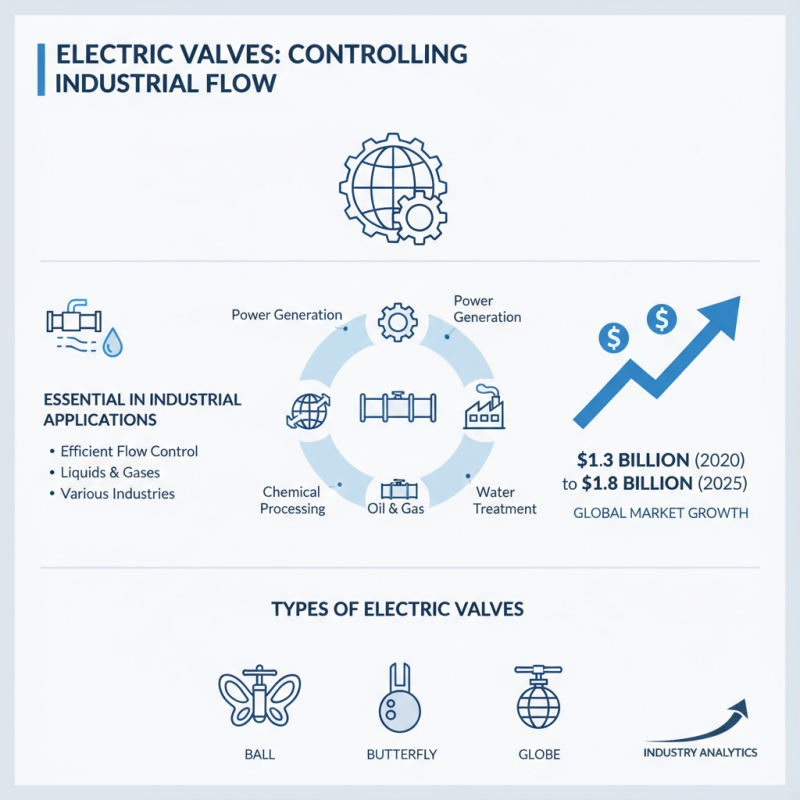

Electric valves are essential in various industrial applications. They control the flow of liquids and gases efficiently. Understanding the different types of electric valves helps in selecting the right one for specific needs. According to a report by MarketsandMarkets, the global electric valve market is expected to grow from $1.3 billion in 2020 to $1.8 billion by 2025, highlighting their increasing importance.

The primary types of electric valves include globe, ball, and butterfly valves. Globe valves are suitable for precise flow control. They manage flow through an angled seat. Ball valves offer quick shut-off capabilities, allowing full flow or none at all. Their design ensures minimal pressure drop. Butterfly valves are lightweight and cost-effective. They are ideal for large volume flows, but may not always provide the best sealing.

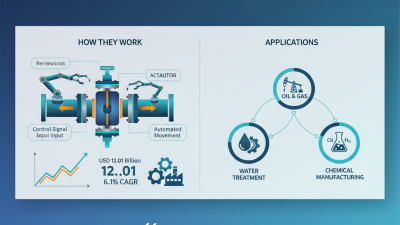

Each valve has its mechanism. The actuator drives the valve open or closed. Electric actuators use motorized control, providing precise positioning. However, these systems can be complex. The challenge lies in maintaining reliability and efficiency. Factors like environment and fluid type influence performance. Regular maintenance is crucial for optimal functionality. Proper selection and sustainability considerations can lead to better outcomes.

Key Applications of Electric Valves in Various Industries

Electric valves play a crucial role in various industries. They control fluid flow, making processes more efficient. For example, in water management, they regulate irrigation systems. This ensures proper water distribution, conserving resources.

In the chemical industry, electric valves handle hazardous materials safely. They prevent leaks and ensure compliance with safety standards. The precision in flow control helps maintain product quality. However, improper installation or maintenance can lead to costly failures. It's essential to address these issues proactively.

In the food and beverage sector, electric valves maintain hygiene. They minimize contamination risks during production. Yet, if not regularly inspected, they can malfunction. This could impact food safety and lead to waste. Therefore, routine checks are vital for optimal performance.

Electric Valves Usage in Industries

Advantages and Limitations of Using Electric Valves

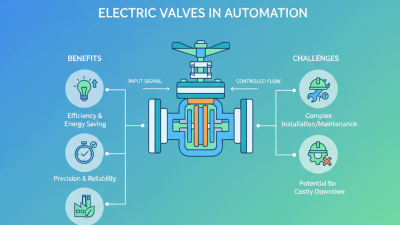

Electric valves are widely used in various automation systems. Their benefits are notable. However, they also come with some limitations.

One significant advantage is precision control. Electric valves can regulate fluid flow accurately. This makes them ideal for applications requiring tight control. Additionally, they can be operated remotely. This adds convenience in hard-to-reach locations.

Yet, electric valves are not without drawbacks. They often require more maintenance than manual valves. This could lead to unexpected downtime. Also, they can be sensitive to electrical issues. A power failure may render them inoperable.

Tip: Regularly inspect electrical connections. It prevents potential malfunctions.

Another point to consider is cost. Electric valves tend to be more expensive than their manual counterparts. This can strain budgets, especially for smaller projects.

Tip: Evaluate the long-term benefits before making a choice. Sometimes, the investment pays off.

In conclusion, while electric valves offer many advantages, their limitations should be weighed carefully. Understanding these factors helps in making informed decisions.

Maintenance and Troubleshooting of Electric Valves

Electric valves require regular maintenance to ensure optimal performance. According to industry reports, nearly 30% of valve failures result from insufficient maintenance. Routine checks can identify issues before they escalate. Common problems include electrical failures and physical blockages. Monitoring these aspects can reduce downtime significantly.

Troubleshooting electric valves is essential for effective operation. When facing a malfunction, start by checking the power supply. Voltage irregularities can cause erratic valve behavior. A study showed that 15% of valve failures stem from electrical supply issues. Inspecting wiring and connectors is crucial too. Corroded connections often lead to poor performance.

Operators must be aware of wear and tear. Components can degrade over time, impacting functionality. A recent survey reported that 40% of maintenance teams overlook minor wear signs. Regular visual inspections can catch these early. This proactive approach can extend the life of electric valves and improve reliability.