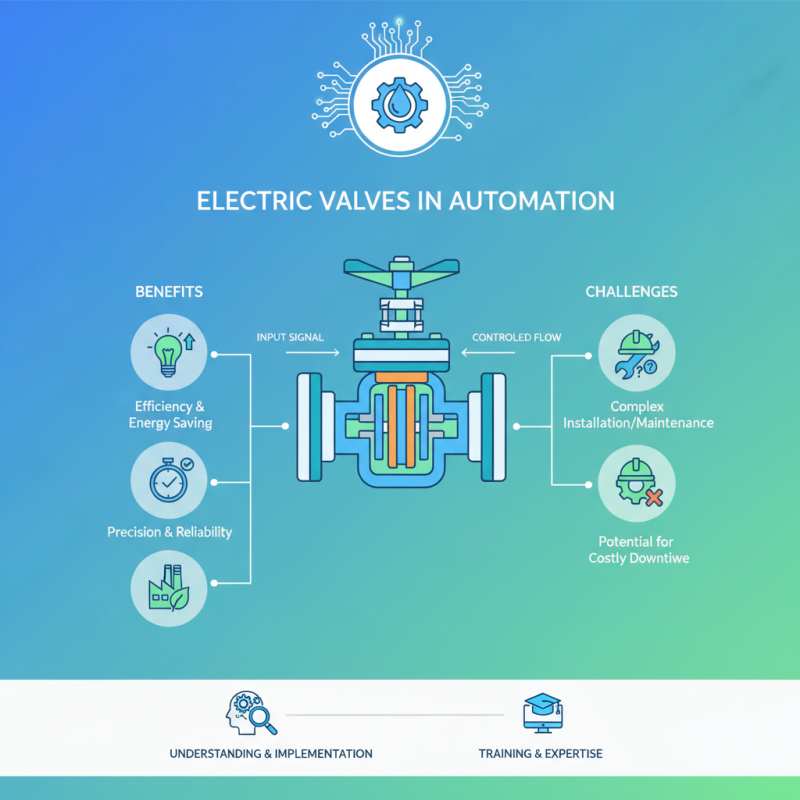

Why Electric Valves are Essential for Modern Automation Systems?

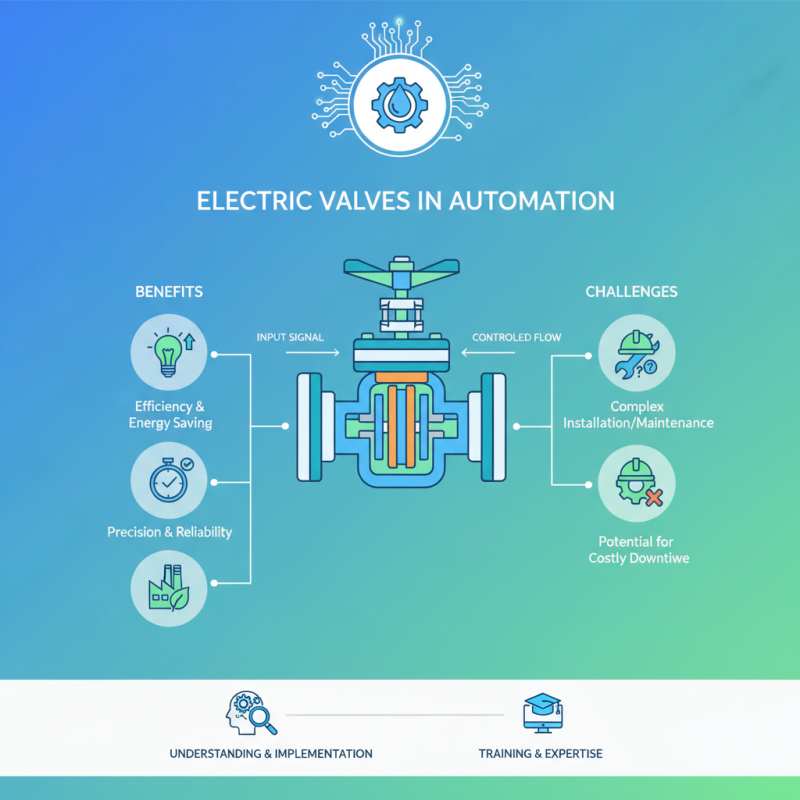

In the realm of modern automation, electric valves play a pivotal role. They act as the essential components that control fluid flow in various systems. From manufacturing plants to water treatment facilities, these valves are everywhere. Their precision ensures efficiency and reliability in operations.

Electric valves respond quickly to signals and manage processes seamlessly. This efficiency reduces energy consumption and waste. However, there can be challenges. Installation and maintenance require careful planning and specialized knowledge. A poorly installed electric valve can lead to operational failures, resulting in costly downtime.

Understanding the importance of electric valves is crucial for enhancing automation systems. As industries continue to evolve, the demand for effective control solutions grows. Embracing this technology is not just an option; it's a necessity for future success. Yet, we must reflect on implementation and training to avoid potential pitfalls.

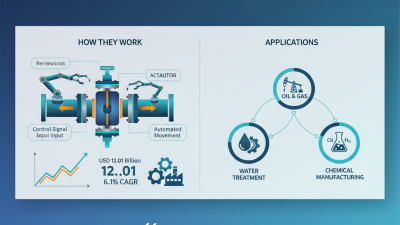

Definition and Functionality of Electric Valves in Automation

Electric valves play a crucial role in modern automation systems. They control the flow of fluids, ensuring efficient operation. By receiving signals from control systems, electric valves can open or close as needed. This precise control allows for improved efficiency and reliability in various applications.

These valves function through electric actuators that convert electrical energy into mechanical movement. They can handle diverse media, from water to chemicals. This versatility makes them an integral component in industries like manufacturing, energy, and water treatment.

However, selecting the right type of electric valve can be challenging. One must consider factors such as pressure, temperature, and the nature of the fluid. An improper choice can lead to failures or decreased performance. Regular maintenance is also essential to ensure longevity.

While electric valves offer many benefits, their dependency on electric power should not be overlooked. This can lead to risks in power outages. Hence, understanding their functionality is vital for any automation system's success.

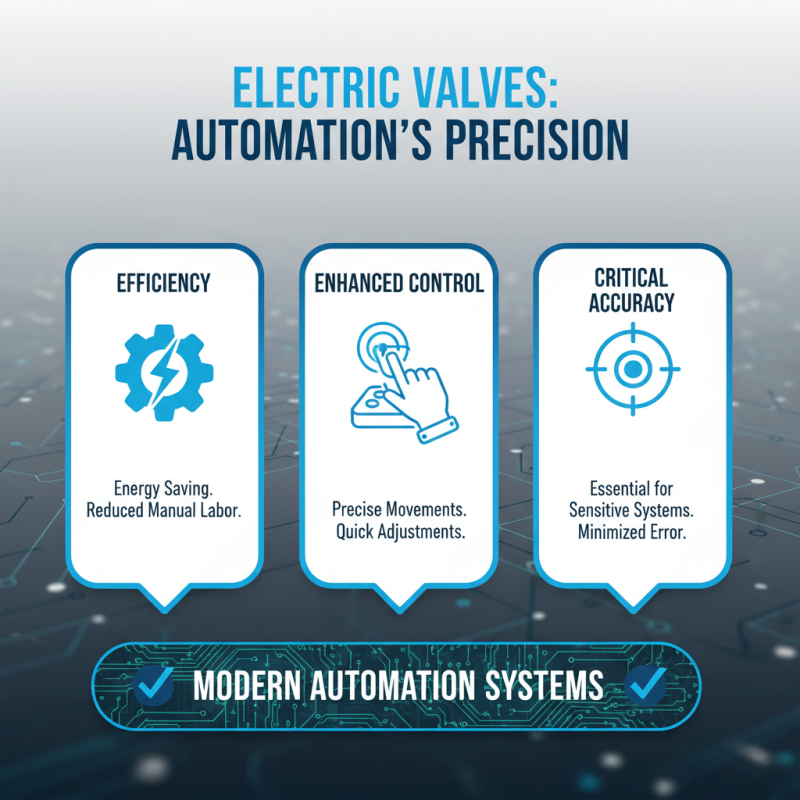

Advantages of Electric Valves Compared to Traditional Valve Systems

Electric valves play a crucial role in modern automation systems. They are more efficient and easier to control than traditional valve systems. With electric valves, operators can execute precise movements and adjustments quickly. This level of control is essential in environments where accuracy is key.

One significant advantage is their ability to integrate with smart technologies. They can monitor status in real time, allowing for immediate responses to changes. Traditional valves often lack this capability, making troubleshooting tedious. Electric valves also consume less energy over time, promoting sustainable practices within industries. Yet, initial costs can be higher, which raises questions about short-term versus long-term investment.

Installation and maintenance present challenges too. While typically easier to set up, electric valves can require specialized training. This complexity can confuse some users, especially in smaller operations. Operators must understand the technology to avoid potential mishaps. Electric valves also face issues like power outages, leading to potential system failures if not backed up properly. Balancing these factors is essential for effective decision-making in automation systems.

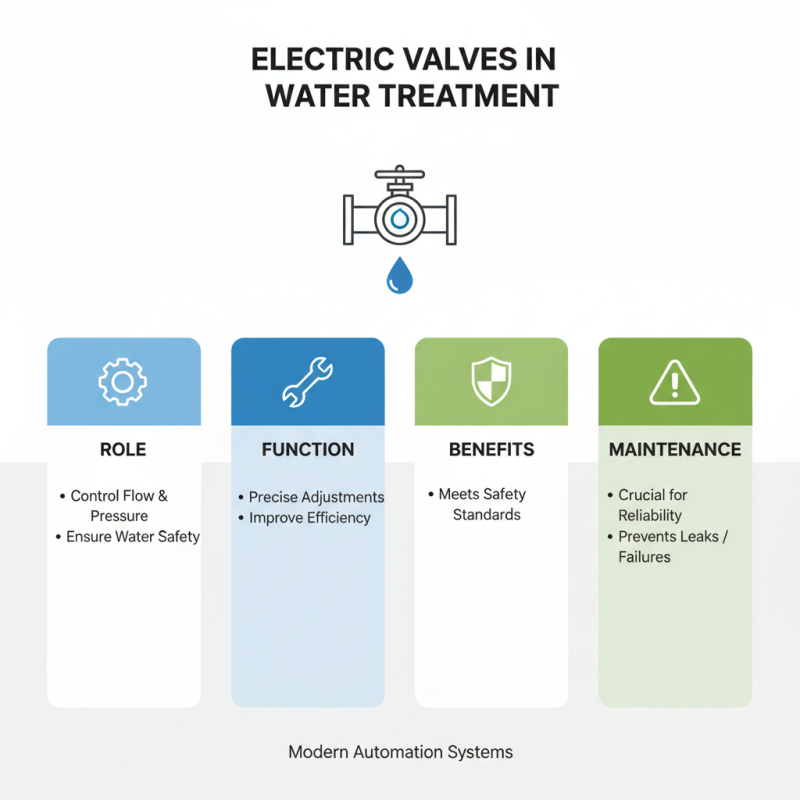

Applications of Electric Valves in Various Industries

Electric valves play a pivotal role in modern automation systems across various industries. They are commonly used in water treatment facilities. In these settings, electric valves help control the flow and pressure of water. This ensures that the water meets safety standards before distribution. They allow for precise adjustments, improving operational efficiency. However, maintenance is crucial; neglect can lead to leaks or system failures.

In the pharmaceutical sector, electric valves assist in maintaining sterile environments. They regulate the flow of liquids used in drug manufacturing. A malfunction could result in contamination or production delays, impacting safety. Moreover, in chemical plants, these valves control hazardous materials. Operators must ensure they function correctly to prevent dangerous spills. Regular inspections are often overlooked but are essential for long-term reliability.

Electric valves are also vital in food and beverage industries. They maintain precise temperatures during processing. However, their installation can be complicated. Misalignment or improper wiring can lead to costly errors. Despite these challenges, as automation trends grow, the importance of electric valves cannot be overstated.

Impact of Electric Valves on System Efficiency and Control

Electric valves play a critical role in modern automation systems.

They enhance system efficiency through precise control over fluid flow.

When integrated into a system, these valves can respond to real-time data.

They adjust flow rates or pressure effortlessly. This leads to better energy management and reduced wastage.

However, the impact of electric valves is not always straightforward.

Inconsistent performance can arise from inadequate calibration or maintenance.

Regular inspections are necessary to ensure optimal operation.

If left unmonitored, these valves may introduce inefficiencies. This could hamper overall system performance.

In modern automation, the control of processes is pivotal.

Electric valves provide accurate control that boosts reliability.

Yet, as technology evolves, they also demand attention.

Understanding their limitations is essential for continuous improvement.

A well-managed system ensures that electric valves contribute effectively to operational goals.

Future Trends and Innovations in Electric Valve Technology

Electric valve technology continues to evolve, playing a crucial role in modern automation systems. One notable trend is the integration of smart technologies into electric valves. These valves now often feature sensors and connectivity options. This development allows for real-time monitoring and data collection. Operators can make informed decisions more quickly. However, implementing these technologies can be challenging. Not all facilities have the infrastructure to support such advancements.

Another notable innovation is the move towards energy efficiency. Manufacturers are focusing on reducing energy consumption in electric valves. Use of advanced materials and designs achieves this goal. In addition, many new electric valves offer faster response times. This enhances overall system performance. However, some older systems may struggle to adapt. Companies may need to invest in upgrades to stay current.

The future of electric valve technology is also focused on enhanced durability. New materials promise improved resistance to corrosion and wear. These innovations aim to extend the lifespan of electric valves. Yet, as technology advances, the complexity of maintenance may increase. Proper training for personnel will become essential. As the industry progresses, continuous evaluation will be necessary. Companies must be willing to adapt to ensure they benefit from these innovations.

Why Electric Valves are Essential for Modern Automation Systems? - Future Trends and Innovations in Electric Valve Technology

| Feature |

Advantages |

Application Areas |

Future Innovations |

| Automation |

Increases efficiency and reduces manual errors |

Manufacturing, Chemical Processing |

AI integration for predictive maintenance |

| Precision Control |

Allows for exact fluid management |

Pharmaceuticals, Food Industry |

Smart technology for real-time monitoring |

| Remote Operation |

Enables control from a distance, enhancing safety |

Oil and Gas, Water Treatment |

Internet of Things (IoT) applications |

| Energy Efficiency |

Reduces power consumption compared to pneumatic systems |

HVAC, Renewable Energy |

Development of energy-harvesting technologies |

| Durability |

Long service life with minimized maintenance needs |

Mining, Heavy Industry |

Advanced materials for increased lifespan |