Why Are Flow Valves Essential for Efficient Fluid Control?

Efficient fluid control is vital in various industries. A crucial component in this system is the flow valve. Flow valves regulate the flow rate and pressure of fluids. They allow for optimal performance in piping systems. Without these valves, fluid dynamics could suffer greatly.

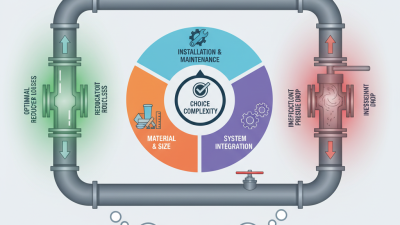

Different types of flow valves exist. Each type offers unique benefits and challenges. For instance, some are better for high-pressure applications, while others excel in low-flow scenarios. Understanding these differences is essential, yet many overlook this. There is a common assumption that any flow valve can work in all situations. This misconception can lead to inefficiencies and costly errors.

Incorporating the right flow valve can lead to energy savings and improved system reliability. However, failing to do so may result in leaks and maintenance issues. A closer examination of flow valve selection is necessary. Regular evaluations of valve performance can reveal hidden problems. This exploration into the significance of flow valves can enhance our understanding of fluid control systems.

The Role of Flow Valves in Fluid Dynamics

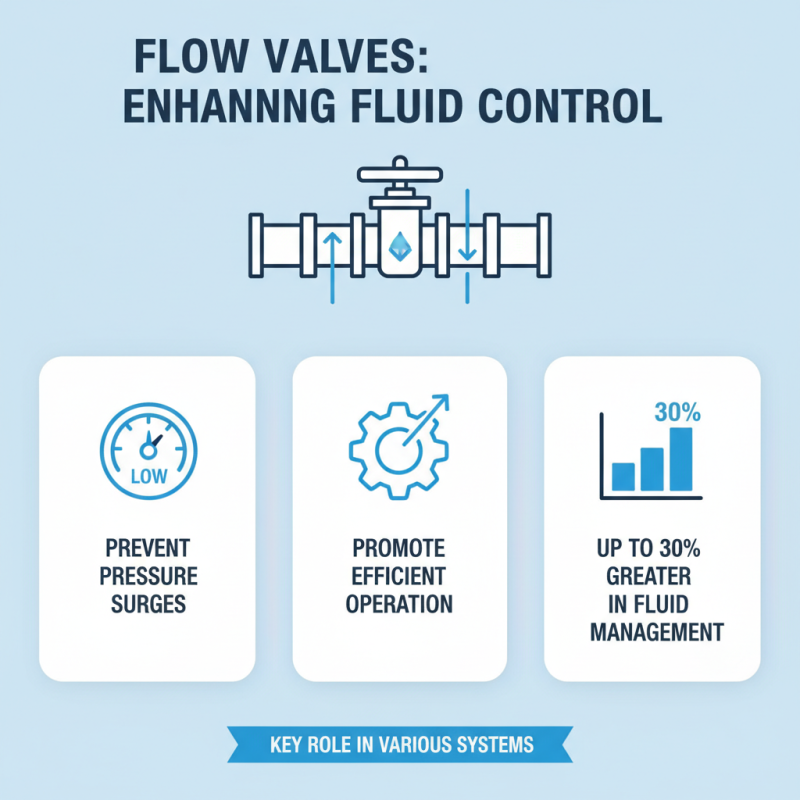

Flow valves play a critical role in fluid dynamics. They regulate the flow rate, pressure, and direction of fluids in various systems. According to a report from the Global Flow Control Market, the demand for efficient flow valves is increasing at a rate of 5.8% annually. This highlights their importance in industries like water treatment, oil and gas, and HVAC.

These devices ensure that systems operate smoothly and without waste. Accurate flow control can lead to energy savings of up to 30%. However, many systems still struggle with flow regulation. Issues such as wear and tear can compromise performance. Regular maintenance is essential to prevent failures that could disrupt operations and lead to costly downtime.

The complexity of fluid dynamics requires precise control. Adjusting a flow valve can significantly impact system efficiency. Yet, many operators lack the necessary training. Understanding how to optimize valve settings is crucial. Careful monitoring and adjustments can lead to better performance and lower operating costs over time.

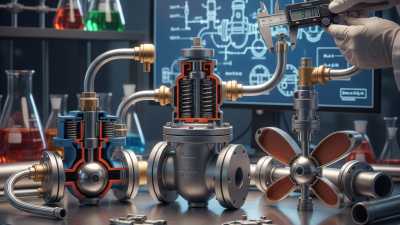

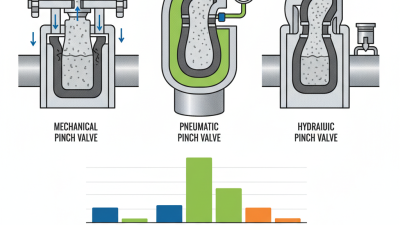

Types of Flow Valves and Their Applications

Flow valves play a crucial role in fluid control systems. They are designed to manage the direction, rate, and pressure of fluids. Each type has unique features that cater to specific applications.

One common type is the globe valve. It allows for precise flow regulation, making it ideal for throttling. Another is the gate valve, known for its straightforward design. It provides minimal resistance when fully open, suitable for on/off applications. Ball valves are popular for their quick operation and robust sealing. They are widely used in pipelines. However, the selection of a valve can be challenging. Each application has varying requirements. A misunderstanding of these can lead to inefficient systems.

Butterfly valves are versatile and lightweight. They excel in controlling flow in large pipes. Yet, they may suffer from wear over time. Check valves, on the other hand, prevent backflow. Their function is crucial in many scenarios, but improper installation can cause failures. Each type highlights the importance of understanding the system’s needs. Careful consideration is necessary for optimal fluid control. Choosing the wrong valve can lead to inefficiencies or even costly repairs.

Factors Affecting Flow Valve Performance

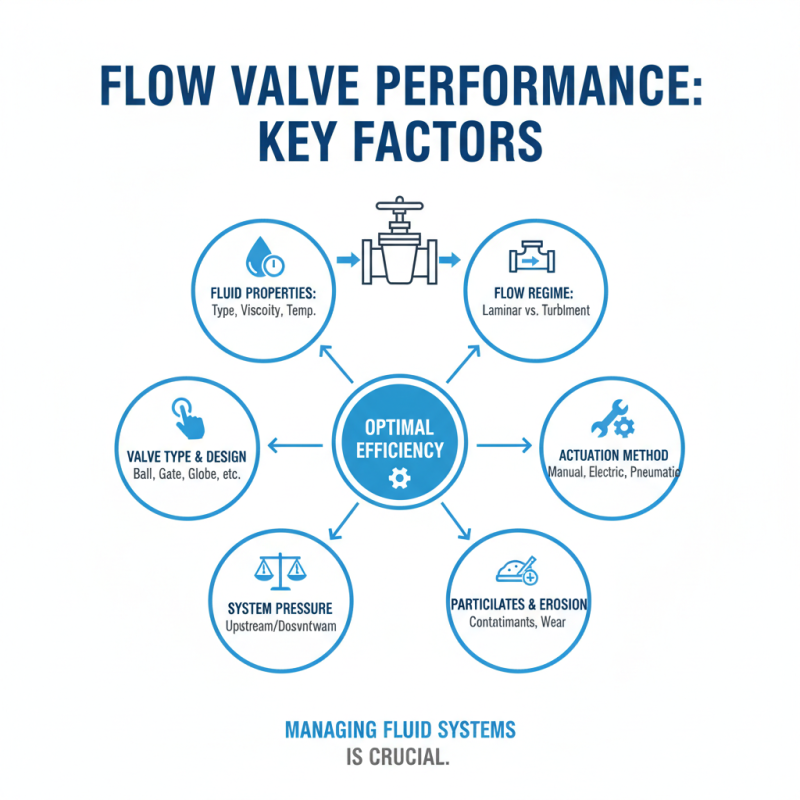

Flow valves play a crucial role in managing fluid systems. Their performance is influenced by various factors. Understanding these elements is key to optimizing their efficiency.

One major factor is pressure. High pressure can enhance flow, but it may also lead to valve wear. If not managed, this could cause leaks. Ensuring proper pressure settings is vital. Temperature also matters. It affects the viscosity of fluids, which, in turn, influences flow rates.

**Tip:** Regularly check the temperature and pressure settings. Small adjustments can lead to significant improvements.

Another important aspect is the type of fluid. Different fluids have varying properties. For example, corrosive fluids can damage valves if incompatible materials are used. Choosing the right materials is essential for longevity.

**Tip:** Evaluate your fluid before selecting a valve. It can save you time and costs later.

Finally, installation and maintenance cannot be overlooked. Poor installation can lead to inefficiencies. Make sure that valves are positioned correctly and regularly assessed. Small maintenance steps can prevent larger issues.

Maintenance Practices for Optimal Flow Valve Functioning

Flow valves play a crucial role in managing fluid dynamics across various industries. However, without proper maintenance, their efficacy declines significantly. Regular inspections can prevent serious operational issues. According to a report from the Society of Mechanical Engineers, about 30% of valve failures arise from inadequate maintenance practices.

Routine maintenance should encompass visual inspections and functional testing. Gaskets, seals, and actuator mechanisms require careful examination for wear. If neglected, even a small leak can disrupt an entire system. Data from the Fluid Control Association reveals that unmaintained valves can lead to a 20% increase in operational costs.

Unexpected failures can happen. Operators may overlook simple tasks like cleaning and lubrication. These small actions can greatly enhance the longevity of flow valves. Implementing a scheduled maintenance plan is essential. It helps in identifying issues early and ensuring fluid control remains efficient without unnecessary downtime.

Flow Valve Maintenance Impact on Efficiency

Regular maintenance practices significantly enhance the efficiency of flow valves. This chart illustrates the percentage improvement in flow efficiency attributed to different maintenance activities, highlighting the importance of consistent maintenance in achieving optimal fluid control.