Exploring the Future of Valve Industries: Innovations Shaping Fluid Control Technology

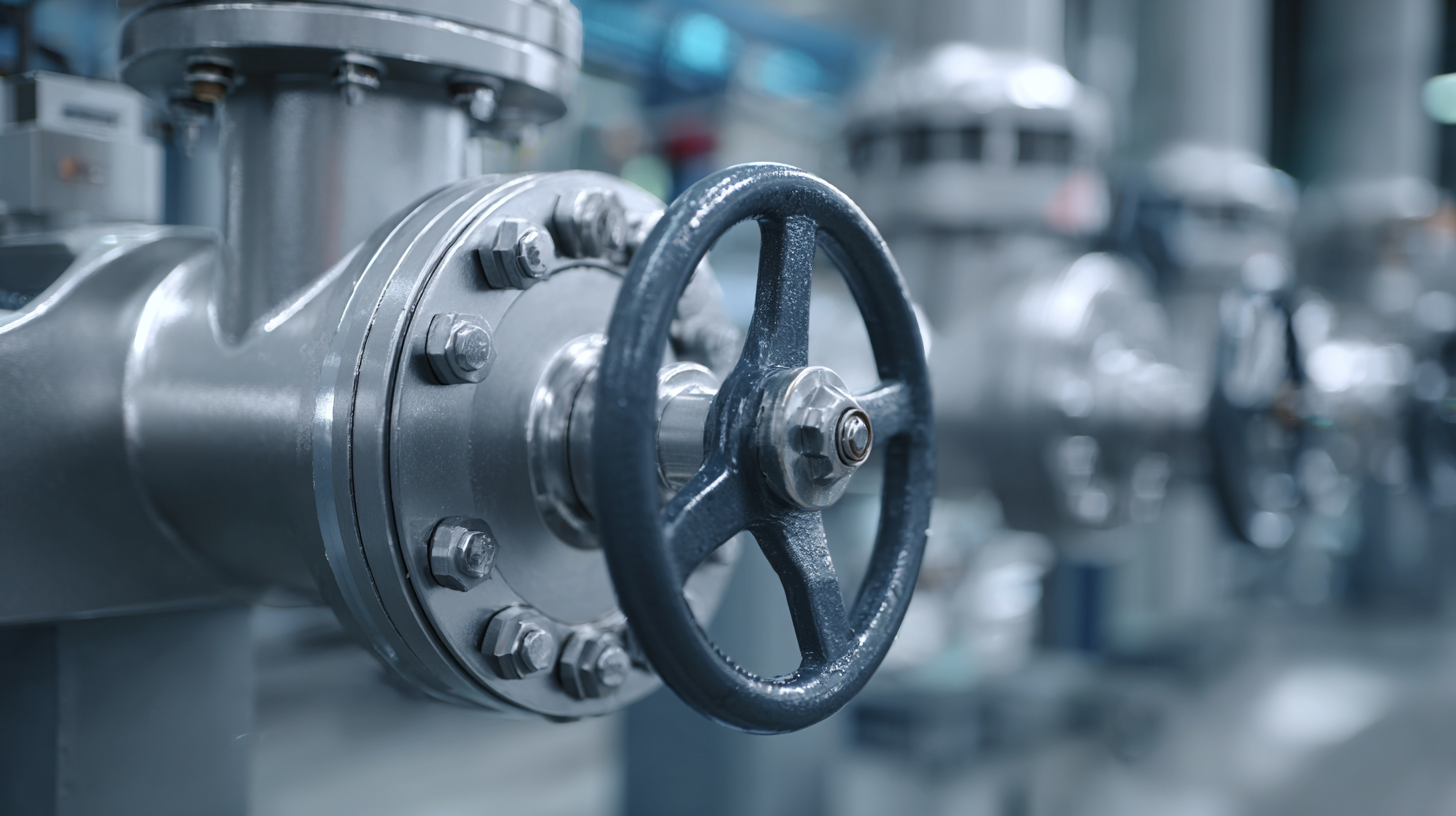

The valve industries are at the forefront of technological innovation, driving advancements that significantly enhance fluid control systems across various applications. As we explore the future of this dynamic sector, it becomes evident that emerging technologies are revolutionizing the way valves are designed, manufactured, and operated. Innovations such as smart valves equipped with IoT capabilities, eco-friendly materials, and advanced automation techniques are shaping a new landscape that emphasizes efficiency, sustainability, and reliability.

This exploration delves into the transformative changes poised to redefine the valve industries, highlighting key developments that promise to enhance performance and address the evolving demands of industries ranging from oil and gas to water management. By examining these innovations, we aim to provide insights into the trajectory of fluid control technology and its implications for the global market, ensuring that we remain at the cutting edge of this critical field.

The Role of Smart Technologies in Advancing Valve Industry Innovations

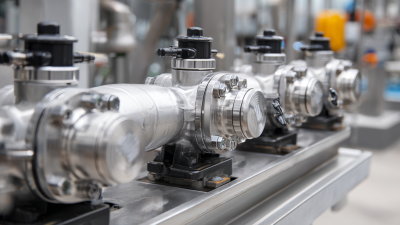

The integration of smart technologies in the valve industry is revolutionizing the way fluid control systems operate. Advanced sensors and IoT devices enable real-time monitoring and data collection, allowing operators to gain insights into valve performance and process efficiency. This shift towards automation not only enhances decision-making but also reduces operational risks by providing timely alerts for maintenance and potential failures. As a result, industries are seeing improved reliability and reduced downtime, which are critical for maintaining competitive advantage.

Moreover, smart technologies facilitate predictive maintenance by utilizing data analytics and machine learning algorithms. These innovations help to foresee issues before they escalate, allowing for maintenance to be scheduled at optimal times, thereby minimizing disruptions. Additionally, the ability to remotely manage and adjust valve operations increases flexibility and responsiveness in dynamic industrial environments. As these technologies continue to evolve, they will play a crucial role in driving the future of the valve industry, fostering innovations that enhance sustainability and operational efficiency across various sectors.

Integrating AI and Machine Learning for Enhanced Fluid Control Solutions

The integration of AI and machine learning in valve industries is revolutionizing fluid control technology. According to a recent report by MarketsandMarkets, the AI in the IoT market is expected to grow from $1.5 billion in 2020 to $5.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 28.3%. This surge in adoption is driven by the need for more efficient and precise fluid control systems that can adapt in real-time to changing conditions. With AI-driven predictive maintenance, operators can significantly reduce downtime and maintenance costs, enhancing operational efficiency.

Moreover, machine learning algorithms enable predictive analytics that significantly optimize valve operation. A report from the International Society of Automation (ISA) indicates that industries utilizing machine learning for fluid control have reported an average efficiency improvement of 15-25%. By analyzing vast amounts of operational data, these AI systems can identify patterns and anomalies, allowing for quicker and more informed decision-making. As the industry continues to embrace these technologies, the future of fluid control systems looks promising, characterized by greater automation and intelligence in operations.

Exploring the Future of Valve Industries: Innovations Shaping Fluid Control Technology

| Innovation Type |

Description |

Impact on Fluid Control |

Implementation Status |

| AI-Driven Predictive Maintenance |

Utilizing AI algorithms to predict failures and optimize maintenance schedules. |

Reduces downtime and maintenance costs, improves reliability. |

In Progress |

| Smart Valve Technology |

Integration of IoT devices for real-time monitoring and control. |

Enhanced operational efficiency and reduced energy consumption. |

Pilot Testing |

| Data Analytics for Fluid Dynamics |

Using machine learning to analyze fluid behavior and optimize system design. |

Improves design accuracy and system performance. |

Research Phase |

| Automated Control Systems |

Advanced algorithms for automated fluid control processes. |

Increases precision and reduces human error in fluid management. |

Deployed |

| Blockchain for Supply Chain Transparency |

Utilization of blockchain technology to enhance supply chain tracking. |

Improves tracking of materials and compliance with regulations. |

In Development |

Sustainable Practices in Valve Manufacturing: Innovations and Challenges

The valve manufacturing industry is experiencing a transformative shift toward sustainable practices, driven by the increasing emphasis on environmental responsibility. As per the Global Valve Market Report, the global valve market is projected to reach USD 80 billion by 2025, growing at a CAGR of 4.3%. This growth is largely influenced by innovations aimed at reducing the carbon footprint of production processes. Implementing eco-friendly materials, such as recycled metals and biodegradable polymers, not only minimizes environmental impact but also caters to the growing demand for sustainable engineering solutions from industries like oil and gas, water treatment, and HVAC.

Challenges remain, however, as manufacturers must navigate the complexity of transitioning to sustainable practices while maintaining cost efficiency. According to the Valve Manufacturers Association, 60% of manufacturers cite the high initial investment in sustainable technology as a significant barrier to implementation. Furthermore, ensuring consistent quality and performance while using alternative materials presents an additional hurdle. Yet, the long-term benefits of sustainability—such as enhanced brand reputation and compliance with increasingly stringent environmental regulations—are compelling enough for industry leaders to invest in research and development focused on green innovations. These efforts will redefine fluid control technology and potentially reshape market dynamics in the years to come.

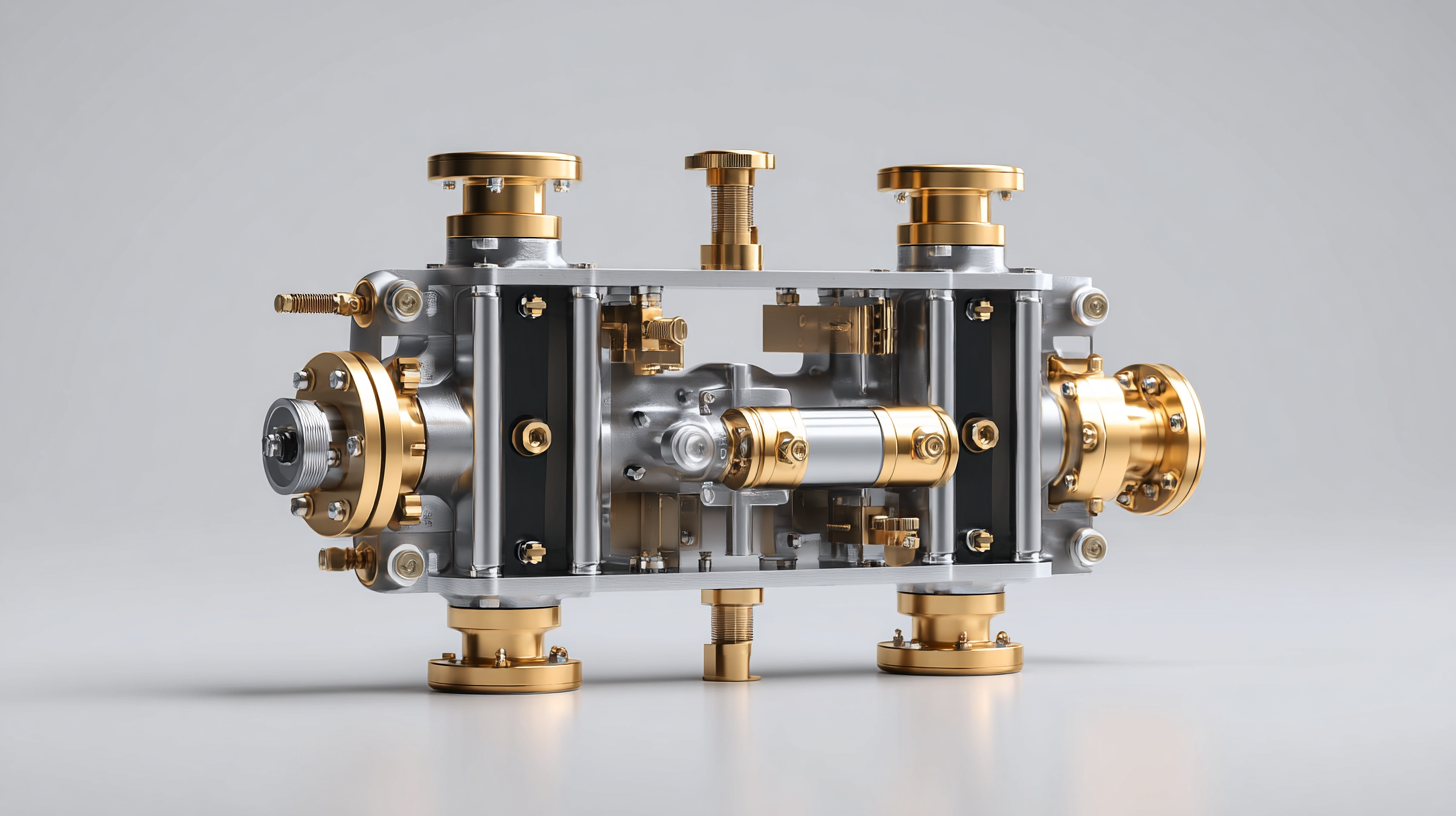

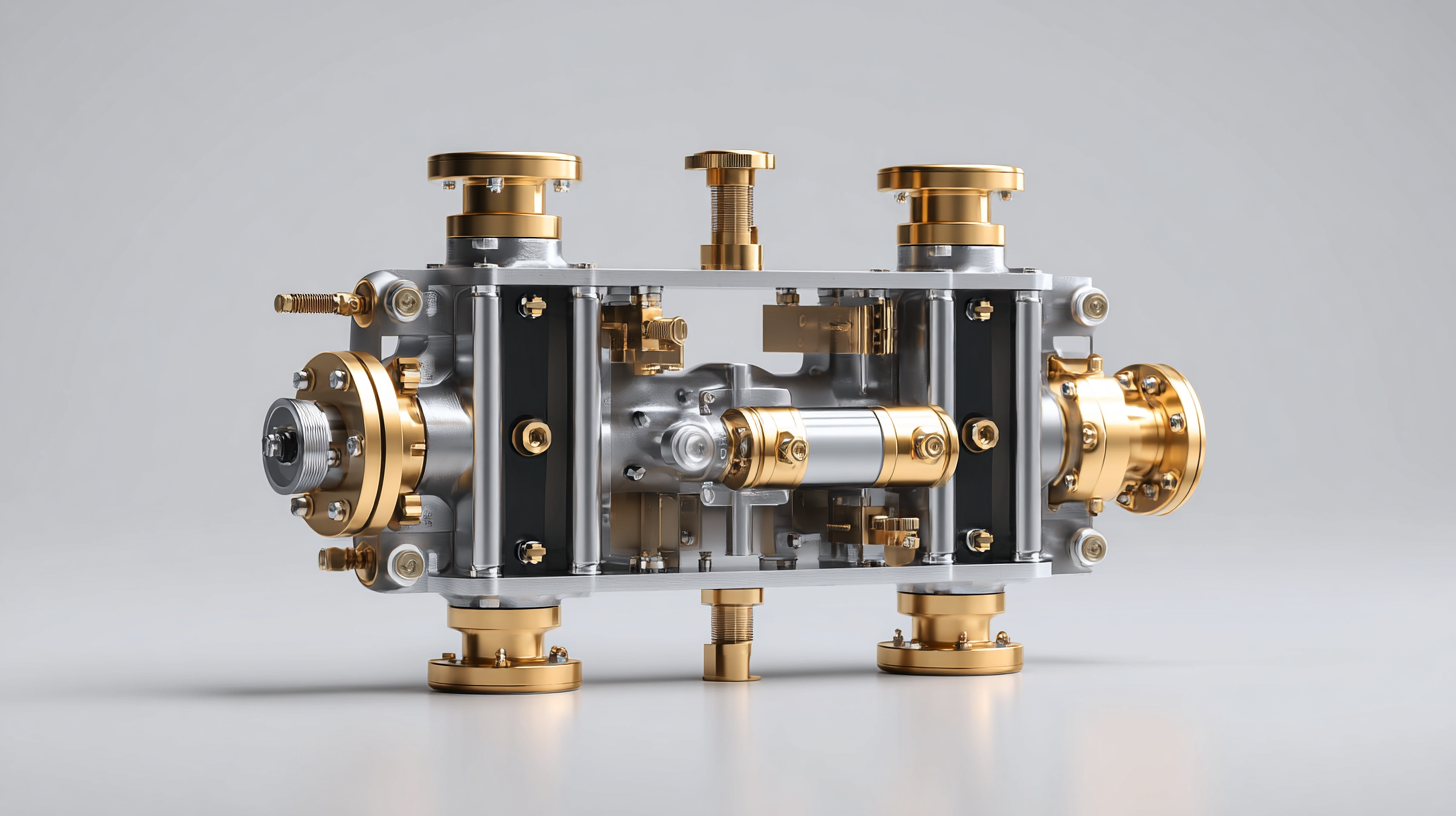

Future Trends in Valve Design: From Traditional to Smart Systems

As the automotive industry evolves, so does the valve sector, which is adapting to the demands of smarter and more efficient fluid control systems. The global automotive valve market is anticipated to reach a value of $1,117.2 million by 2025, with a steady compound annual growth rate of 1.8% projected until 2033, signaling a transformative phase. This growth reflects a shift from traditional valve designs to intelligent, software-driven solutions.

In the era of software-defined vehicles, innovations in valve design are paramount. The integration of smart systems into fluid control technology not only enhances vehicle performance but also contributes to the overall efficiency of electric and autonomous driving systems. As manufacturers embrace these advancements, the competitive landscape will favor those who prioritize adaptability and technological integration.

**Tips:** When considering valve advancements, pay attention to the materials used in construction for durability and performance. Additionally, keeping informed about the latest automation technologies will be crucial for understanding industry shifts. Emphasizing sustainable practices in the design and manufacturing of valves will also be essential as regulations evolve.

The Impact of IoT on Valve Performance and Operational Efficiency

The integration of the Internet of Things (IoT) in valve industries is revolutionizing fluid control technology, significantly enhancing valve performance and operational efficiency. According to a recent report by MarketsandMarkets, the IoT in the industrial sector is expected to grow from $64.6 billion in 2020 to $113.6 billion by 2025, demonstrating a compound annual growth rate (CAGR) of 11.3%. This rapid growth is driven by advancements in smart sensors and connectivity, enabling real-time monitoring and data analysis of valve operations.

As valves become smarter through IoT integration, they can communicate vital performance metrics and operating conditions back to centralized control systems. This capability not only allows for predictive maintenance—reducing downtime by up to 30% according to a study by McKinsey—but also improves energy efficiency by optimizing valve responsiveness based on real-time data. For instance, IoT-enabled valves can automatically adjust flow rates based on demand fluctuations, thus minimizing waste and ensuring resource conservation. Such innovations underscore the critical role of IoT in shaping the future of valve technologies, driving industries toward more efficient and sustainable operations.

Innovations in Valve Performance and Operational Efficiency

This chart illustrates the comparison of operational efficiency and performance metrics before and after the implementation of IoT technology in valve manufacturing. The data shows a significant improvement in both operational efficiency (from 65% to 85%) and a reduction in latency (from 200 ms to 90 ms) after integrating IoT solutions, highlighting the transformative impact of technology in fluid control systems.