Exploring Gas Valve Innovations at the 138th Canton Fair 2025: Insights and Industry Trends

As the 138th Canton Fair approaches in 2025, the focus on gas valve innovations has become increasingly significant in the global manufacturing landscape. This biennial event, renowned for showcasing the latest advancements in various industries, serves as a prime platform for manufacturers and suppliers to unveil their cutting-edge gas valve technologies. With the rise of automation and smart home systems, understanding the newest trends in gas valve design, functionality, and safety standards is essential for industry stakeholders. Attendees can expect to gain invaluable insights into how these innovations can enhance efficiency, reduce environmental impact, and meet the evolving demands of consumers. In this context, exploring the intersection of technology and regulatory requirements will be crucial, as the gas valve sector adapts to challenges and opportunities in an ever-changing market.

Innovative Gas Valve Technologies Showcased at the 138th Canton Fair 2025

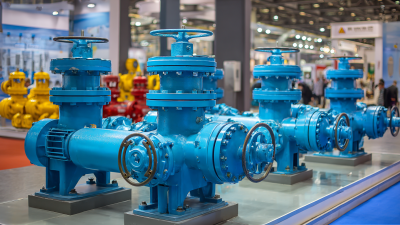

At the 138th Canton Fair 2025, the spotlight will be on innovative gas valve technologies that are transforming the industry. This year's exhibition is expected to attract a record number of exhibitors, with over 28,000 participants showcasing their latest advancements. Notably, the demand for smart gas valve solutions has surged, driven by the need for improved safety and efficiency in the energy sector. According to industry reports, the global gas valves market is projected to reach a value of USD 8.4 billion by 2026, growing at a CAGR of 5.7%. This growth is fueled by innovations that enhance operational reliability and support automation initiatives.

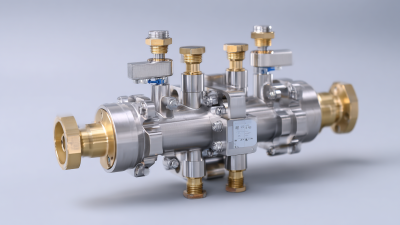

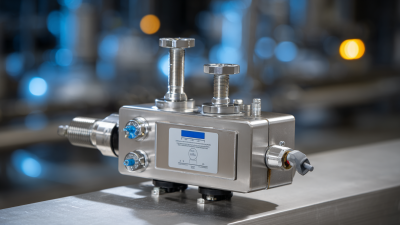

Highlighted innovations include the integration of intelligent manufacturing technologies in valve production. Similar to recent trends seen in filtration technology at the Canton Fair, gas valve manufacturers are aiming to improve performance metrics through advanced manufacturing processes. The introduction of electronic actuators and IoT capabilities in gas valves exemplifies the shift towards smarter, more responsive systems. This evolution not only meets stringent safety regulations but also caters to the growing emphasis on energy efficiency in industrial applications. As the industry marches forward, the Canton Fair will serve as a vital platform for unveiling these cutting-edge technologies and discussing future trends in gas valve applications and safety measures.

Market Demand Trends for Gas Valves in Asia-Pacific Region

The gas valve market within the Asia-Pacific region is undergoing significant transformation, driven by increasing industrial activities and a growing demand for efficient energy solutions. According to a recent report by Mordor Intelligence, the gas valve market in Asia-Pacific is expected to grow at a CAGR of 6.5% from 2023 to 2030, reflecting the rising reliance on natural gas as a cleaner alternative to coal. This shift is especially prominent in countries like China and India, where industrialization and urbanization are propelling the need for advanced gas management systems.

Moreover, the adoption of cutting-edge technologies such as smart valves is reshaping the industry landscape. A study by MarketsandMarkets highlights that the smart valve segment is projected to grow significantly, with a contribution of nearly 25% to the overall gas valve market by 2025. These innovations are facilitating enhanced automation, remote monitoring, and better safety protocols, responding to the stringent regulatory frameworks that govern energy consumption in the region. As the 138th Canton Fair in 2025 showcases these advancements, it will be a pivotal platform for stakeholders to explore novel strategies and forge partnerships that align with market demands.

Impact of Smart Technology on Gas Valve Performance and Reliability

The 138th Canton Fair in 2025 promises to be a landmark event for gas valve innovations, particularly as smart technology significantly impacts performance and reliability. As industries increasingly adopt automation and IoT capabilities, manufacturers are integrating advanced sensors and control systems into gas valves. This ensures real-time monitoring and precise management of gas flow, enhancing both safety and efficiency. With the implementation of predictive maintenance, issues can be detected and addressed before they escalate, reducing downtime and operational costs.

Moreover, smart technologies are redefining the standards for gas valve reliability. Enhanced data analytics allow for better decision-making, as users can assess performance metrics and operational trends. The ability to remotely manage and diagnose systems not only streamlines maintenance but also optimizes resource usage. This shift towards smart gas valves reflects a broader industry trend towards sustainability, where energy savings and improved safety protocols are becoming paramount. The innovations showcased at this year’s Canton Fair will likely set the stage for the future of gas control systems, where technology and reliability go hand in hand.

Sustainability Efforts in Gas Valve Manufacturing: A 2025 Perspective

The 2025 gas valve manufacturing sector is increasingly focusing on sustainability as a core component of innovation strategies. As industries worldwide shift towards greener practices, manufacturers are adopting new technologies that minimize waste and reduce environmental impact. Notably, the recent advancements in green hydrogen production technologies reflect a significant pivot within energy sectors, which are increasingly exploring hydrogen as a cleaner fuel alternative. According to a report by the International Energy Agency, global hydrogen demand could reach 500 million tons by 2050, driven largely by industrial applications, including gas valve solutions that align with hydrogen energy.

Additionally, the integration of Lean Six Sigma methodologies within manufacturing processes offers a pathway to enhance operational efficiency while advancing sustainability goals. Applying these principles can lead to waste reduction, which is crucial in the production lifecycle of gas valves. The Manufacturing Outlook report for 2025 highlights that manufacturers focusing on sustainable practices are likely to see a 25% increase in productivity compared to their counterparts who do not prioritize these initiatives. This not only supports environmental goals but can also enhance the overall competitiveness of manufacturers in the gas valve industry.

Emerging Competitors in the Global Gas Valve Industry and Market Share Analysis

The global gas valve industry is witnessing significant growth, driven by innovative technologies and increasing demand for efficient gas pipeline infrastructure. According to a market research study, the global valves market is projected to reach USD 137.90 billion by 2033, with a compound annual growth rate (CAGR) of 6.26% from 2025 to 2033. This upward trend highlights the critical role of gas valves in enhancing operational efficiency and safety within the expanding global gas infrastructure.

Emerging competitors are reshaping the landscape of the gas valve market. A competitive analysis of the Saudi Arabia industrial valves sector indicated that the market is expected to grow from USD 3.10 billion in 2023 to USD 4.31 billion by 2029, marking a CAGR of 5.50%. As key players look to innovate and maintain market share, they will increasingly focus on developing advanced gas valve technologies. This competitive atmosphere is likely to spur new entrants, pushing the industry toward enhanced performance and sustainability standards, which are crucial for meeting global energy demands.

Gas Valve Market Share Analysis (2025)

This bar chart illustrates the market share distribution of gas valves across different regions in 2025. As shown, the Asia-Pacific region leads the market with a 35% share, followed by Europe at 30%, and North America at 25%. Latin America and the Middle East & Africa hold smaller shares at 5% each.