2026 How to Choose the Right Flow Valve for Your Needs?

Choosing the right flow valve can be challenging. “Understanding your specific needs is crucial,” says Dr. Emily Carter, an expert in fluid dynamics. Flow valves are essential in various industries, controlling fluid movement efficiently.

Selecting the appropriate valve involves assessing flow rates, pressure, and application type. Many overlook critical factors like temperature and material compatibility. However, these elements can greatly impact performance. Each application may require a different valve type, adding complexity to the decision-making process.

Take time to evaluate your system's requirements. Rushing into a choice could lead to inefficiencies or failures. Dr. Carter advises, “Always consult with a professional when in doubt.” Let this guide you in making an informed decision about flow valves.

Understanding the Basics of Flow Valves and Their Applications

When selecting a flow valve, understanding its basics and applications is essential. Flow valves control the flow of liquids or gases in various systems. They come in different types, including ball, gate, and globe valves. Each type serves specific purposes and operates under different conditions.

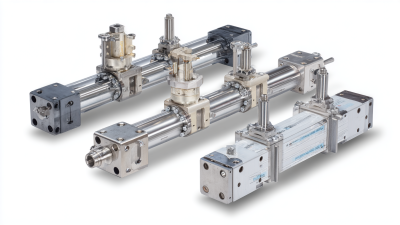

Consider the material of the valve. Different environments may require valves made from stainless steel, brass, or plastic. For instance, corrosive liquids need corrosion-resistant valves. Pay attention to the valve's pressure rating. Ensure it matches the system's requirements to avoid failures.

Tips: Always check compatibility. Wrong materials can lead to leaks or failures. Size is also crucial. An oversized valve may waste energy, while an undersized one can restrict flow. Lastly, think about future maintenance. Some valves are easier to repair than others. Choosing wisely can save time and resources later on.

Identifying Key Factors in Selecting a Flow Valve

Choosing the right flow valve can be daunting. There are many factors to consider. Size is critical. A valve too large or small won’t perform well. Assess the pipe system carefully. Too much pressure can damage components. A mismatch in size is an easy mistake to make.

Next, consider the material of the valve. Different materials handle various fluids differently. For example, corrosive substances require specific materials. Stainless steel may work better than plastic in certain situations. Always check compatibility.

Flow rate is another essential factor. It dictates how much fluid passes through the valve. Accurately determine the required flow rate. Too high or too low can lead to inefficiencies. Calculate this based on system needs. Don’t forget to think about future requirements. Adjustments may be needed later.

Evaluating Different Types of Flow Valves for Specific Needs

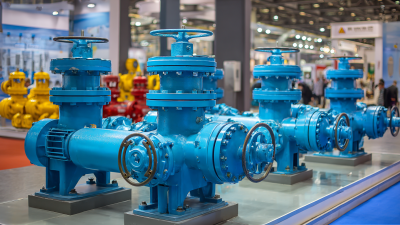

When selecting a flow valve, understanding your specific needs is crucial. Different applications require different types of valves. You might need a ball valve for quick shut-off. Alternatively, a gate valve could suit high-flow situations. Think carefully about the environment. Is it high-pressure or low-pressure? This factors in significantly.

Material matters too. Stainless steel works well for corrosive fluids. Plastic valves may be lighter and cheaper. You may find yourself drawn to one option initially, but consider long-term effects. Sometimes, the cheaper choice leads to more frequent replacements. Also, evaluate the flow rate you need. Not every valve handles the same volume effortlessly.

Size cannot be overlooked. A valve too small can restrict flow, causing inefficiency. Conversely, a valve that’s too large may lead to wasted energy. It’s worth taking the time to get these details right. Don’t let excitement cloud your judgment. It’s okay to revisit your choices and questions. Reflection on what best meets your operational needs is key for success.

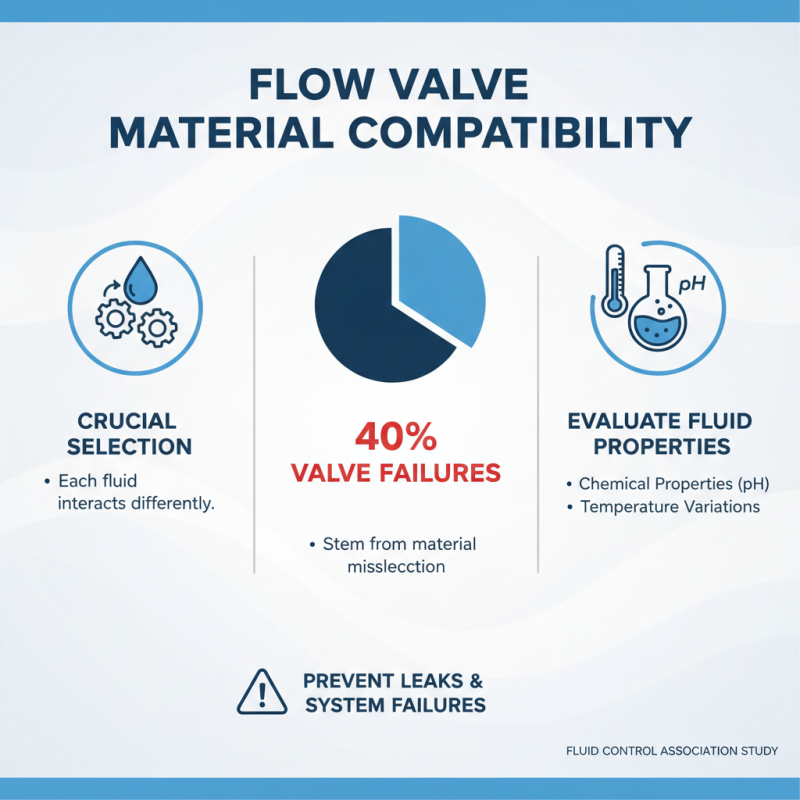

Assessing Material Compatibility and Environmental Considerations

When selecting a flow valve, material compatibility is crucial. Each fluid interacts differently with various materials. For instance, a study conducted by the Fluid Control Association revealed that 40% of valve failures stem from material misselection. Using inappropriate materials can lead to leaks and system failures. It's essential to evaluate the chemical properties of the fluid, including pH levels and temperature variations.

Environmental considerations also play a key role. Valves in harsh environments must resist corrosion and wear. According to industry reports, valves used in corrosive environments should be made from specialized alloys or coated materials. However, these options often face limitations, such as higher costs and complex maintenance needs. The impact of temperature changes on materials can also degrade performance over time.

It's worth noting that sustainability is now at the forefront of industrial decision-making. A recent survey indicated that 70% of professionals consider eco-friendly materials essential when choosing valves. Yet, balancing performance and environmental concerns is no easy task. Companies often grapple with the trade-offs between durability and environmental compliance. This reflects the need for careful evaluation and an informed approach in selecting the right flow valve.

Making Informed Decisions: Cost vs. Performance in Flow Valve Selection

Choosing the right flow valve requires careful consideration of both cost and performance. Industry reports suggest that the decision can significantly impact overall operational efficiency. According to a survey by the Flow Control Association, 40% of users prioritize performance over price. This can lead to higher upfront costs, but better reliability and longevity.

Performance metrics can vary widely. For example, valving materials and designs can affect flow rates and pressure drops. A study from the American Society of Mechanical Engineers shows that a 10% increase in efficiency can save up to 15% in operational costs. However, many buyers overlook these details in favor of a lower initial price. This often results in higher maintenance costs down the line.

Users sometimes struggle to balance budget constraints with performance goals. Selecting a low-cost valve may seem beneficial initially but can lead to frequent failures. Such decisions often come back to haunt users, as the need for replacements due to performance issues accumulates unplanned expenses. The key lies in understanding both sides holistically.

Performance vs. Cost of Different Flow Valve Types