The Role of Industrial Valves in Enhancing Energy Efficiency in Manufacturing

In the quest for improved energy efficiency within the manufacturing sector, industrial valves play a pivotal role that cannot be overlooked. According to a report by the International Energy Agency (IEA), industrial processes account for approximately 30% of global energy consumption, with a significant portion of this being associated with fluid control systems where industrial valves are critical. These valves not only regulate flow and pressure but also contribute to minimizing energy waste through optimized system performance and reduced leakage.

In the quest for improved energy efficiency within the manufacturing sector, industrial valves play a pivotal role that cannot be overlooked. According to a report by the International Energy Agency (IEA), industrial processes account for approximately 30% of global energy consumption, with a significant portion of this being associated with fluid control systems where industrial valves are critical. These valves not only regulate flow and pressure but also contribute to minimizing energy waste through optimized system performance and reduced leakage.

A recent study by MarketsandMarkets estimates that the global industrial valves market is projected to reach $87.94 billion by 2027, reflecting the growing recognition of their importance in achieving sustainable manufacturing practices. By understanding and implementing advanced valve technologies, manufacturers can enhance operational efficiency, reduce energy costs, and support environmental sustainability goals, highlighting the indispensable role of industrial valves in modern production settings.

How to Select the Right Industrial Valves for Energy Efficiency in Manufacturing

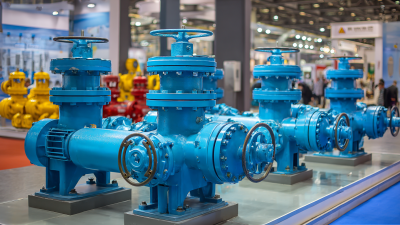

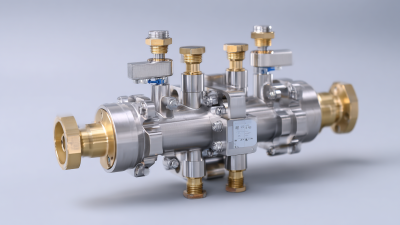

When selecting industrial valves to enhance energy efficiency in manufacturing, it is crucial to consider the specific needs of your operation and the type of fluids involved. Ball valves, for instance, have become increasingly important due to their ability to provide a tight seal and precise control over fluid flow. This precision is vital across various industries, such as oil and gas, pharmaceuticals, and renewable energy, where even minor discrepancies can lead to significant inefficiencies and operational costs.

In the current market, with numerous manufacturers producing a wide variety of valves, discerning the right provider becomes essential. The selection process should involve evaluating the valve's material compatibility, pressure rating, and operational parameters to ensure optimal performance and longevity. Additionally, understanding the trends in the valve market, including the expected growth in specialized sectors like semiconductor applications, can guide businesses in making informed decisions that align with both their immediate needs and future expansion strategies. Selecting the right industrial valves not only improves efficiency but also contributes to the overall sustainability of manufacturing operations.

How to Optimize Valve Placement to Minimize Energy Loss

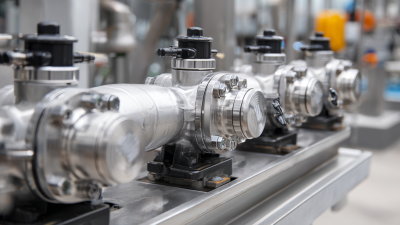

The strategic placement of industrial valves is crucial for optimizing energy efficiency in manufacturing processes. Properly positioned valves can significantly reduce energy loss by minimizing the distance that fluids must travel, thereby decreasing friction and resistance. Placing valves closer to pumps and equipment can help in achieving this efficiency, allowing for smoother transitions and reduced energy expenditure throughout the system. Moreover, utilizing automated control systems to adjust valve positions dynamically can further enhance the efficiency of fluid flow, responding in real-time to varying operational demands.

In addition to placement, regular maintenance and inspection of valves play a vital role in minimizing energy loss. Leaky valves not only waste energy but can also lead to higher operational costs. By implementing a routine maintenance schedule, manufacturers can ensure that valves are functioning optimally, reducing the likelihood of wastage. Moreover, integrating advanced technologies such as predictive analytics can aid in monitoring valve performance and anticipating issues before they escalate, ultimately leading to a more energy-efficient manufacturing environment.

The Role of Industrial Valves in Enhancing Energy Efficiency in Manufacturing

This chart illustrates the impact of optimized valve placement on energy consumption in a manufacturing setting. The data represents the percentage of energy savings achieved at various valve placements.

How to Implement Automated Control Systems for Better Valve Management

Automated control systems play a crucial role in enhancing the management of industrial valves, directly impacting energy efficiency in manufacturing processes. According to a report by the International Energy Agency (IEA), implementing advanced control systems can reduce energy consumption in industrial applications by up to 20% through optimized valve operations. These automated systems enable real-time monitoring and control, allowing for precise adjustments based on dynamic process conditions rather than relying on manual intervention.

Furthermore, the use of predictive analytics in automated control systems enhances valve performance by anticipating maintenance needs and minimizing downtime. A study from the Manufacturing Technology Centre revealed that predictive maintenance can lead to a 10-15% reduction in operational costs. By integrating smart technologies, such as IoT sensors and machine learning algorithms, manufacturers can achieve greater insight into their valve operations. This not only ensures a more efficient use of energy but also extends the lifespan of the valves, contributing to overall operational efficiency and sustainability in the manufacturing sector.

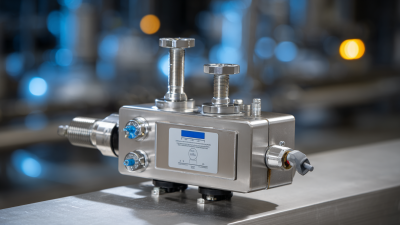

How to Perform Regular Maintenance to Ensure Valves Function Efficiently

Regular maintenance of industrial valves is critical for ensuring their efficiency and longevity, ultimately contributing to enhanced energy efficiency in manufacturing processes. According to industry reports, poorly maintained valves can lead to significant energy losses, with inefficiencies ranging up to 20%. This emphasizes the importance of performing routine checks on components such as actuators, seals, and valve bodies to prevent leaks and pressure drops.

Moreover, maintaining valves involves comprehensive inspections and the calibration of safety valves and instrumentation. For instance, regular maintenance activities can include more than 60 essential tasks, such as valve testing and alignment, which can greatly reduce operational downtime and improve overall system performance. The global industrial valve market is projected to reach USD 80 billion by 2032, driven by the increasing focus on energy efficiency measures and advancements in valve technology. This trend underscores the significance of effective maintenance strategies not just for maximizing valve functionality but also for achieving broader sustainability goals in manufacturing.

The Role of Industrial Valves in Enhancing Energy Efficiency in Manufacturing - How to Perform Regular Maintenance to Ensure Valves Function Efficiently

| Valve Type |

Energy Efficiency Impact (%) |

Maintenance Frequency (Monthly) |

Common Maintenance Tasks |

Expected Lifespan (Years) |

| Gate Valve |

15-20 |

1 |

Inspection, Lubrication |

25 |

| Globe Valve |

10-15 |

2 |

Cleaning, Seat Tightness Check |

20 |

| Ball Valve |

18-25 |

1 |

Visual Inspection, Operation Testing |

30 |

| Check Valve |

5-10 |

2 |

Flow Direction Check |

15 |

| Butterfly Valve |

12-18 |

1 |

Seal Inspection, Stem Packing Adjustment |

25 |

How to Train Employees on Best Practices for Valve Operation and Energy Conservation

Training employees on the best practices for valve operation is crucial for achieving energy efficiency in manufacturing processes.

Industrial valves significantly impact energy consumption, as they regulate flow and pressure in various systems.

According to a report by the U.S. Department of Energy, optimizing valve performance can lead to a reduction in energy wastage by as much as 20%. Therefore, a well-informed workforce can directly influence operational efficiency and energy conservation.

Industrial valves significantly impact energy consumption, as they regulate flow and pressure in various systems.

According to a report by the U.S. Department of Energy, optimizing valve performance can lead to a reduction in energy wastage by as much as 20%. Therefore, a well-informed workforce can directly influence operational efficiency and energy conservation.

To ensure effective training, companies should focus on hands-on experience alongside theoretical knowledge. Employees should be educated about the various types of valves, their functions, and the importance of proper maintenance. Regular workshops can reinforce these concepts.

For example, the training could include practical sessions demonstrating how to identify leaks or improper valve positioning, which can lead to energy loss.

Tips for Effective Training:

- Incorporate interactive simulations that mimic real-life scenarios to help employees practice troubleshooting and valve adjustments.

- Use visual aids, such as infographics, to illustrate the impact of valves on energy consumption, making the benefits of proper operation clear.

Implementing these strategies will empower employees and enhance energy conservation efforts within the manufacturing sector.

In the quest for

In the quest for

Industrial valves significantly impact energy consumption, as they regulate flow and pressure in various systems.

Industrial valves significantly impact energy consumption, as they regulate flow and pressure in various systems.