In the fast-evolving landscape of modern manufacturing, the adoption of advanced technologies is crucial for optimizing production efficiency and reducing operational costs. Among these innovations, the Grooving Machine has emerged as a pivotal tool, enhancing precision in various machining processes. According to a recent report by Markets and Markets, the global CNC machine market is projected to grow from $76.1 billion in 2021 to $117.9 billion by 2026, underscoring the increasing demand for sophisticated machining solutions, including grooving technology. These machines facilitate intricate cut designs and improve material usage, leading to significant time and cost savings. As manufacturers seek to maintain competitive edges, understanding the transformative applications of the best Grooving Machine becomes imperative for capitalizing on industry advancements and achieving sustainable growth.

The evolution of grooving machines has been a pivotal aspect of advancements in manufacturing technology. With the introduction of innovative cutting tools, the dynamics of grooving processes are continually enhanced, leading to improved precision and efficiency. Recent studies highlight a new microgroove cutting tool specifically designed for machining Inconel 718, demonstrating a significant impact on cutting performance. The geometry of these microgrooves directly influences both tool wear and the overall quality of the machined part, emphasizing the critical role that design plays in current and future manufacturing applications.

Tip: When selecting a grooving machine, consider the material you will be working with and the specific geometry of the grooving tools. These factors can significantly affect the efficiency and efficacy of your machining processes.

Furthermore, the introduction of universal symmetric breakdown grooves enables faster process modeling and simulation, allowing for quicker adjustments and optimizations in the manufacturing cycle. This adaptability is crucial, as manufacturers face increasingly complex production demands. The ongoing research into innovative grooving techniques not only reveals the evolving landscape of machining technologies but also underscores the necessity for manufacturers to stay abreast of technological advancements.

Tip: Incorporate real-time monitoring systems that leverage in-process current signals. These tools can provide immediate feedback on passivation changes, optimizing tool performance and extending tool life in demanding applications.

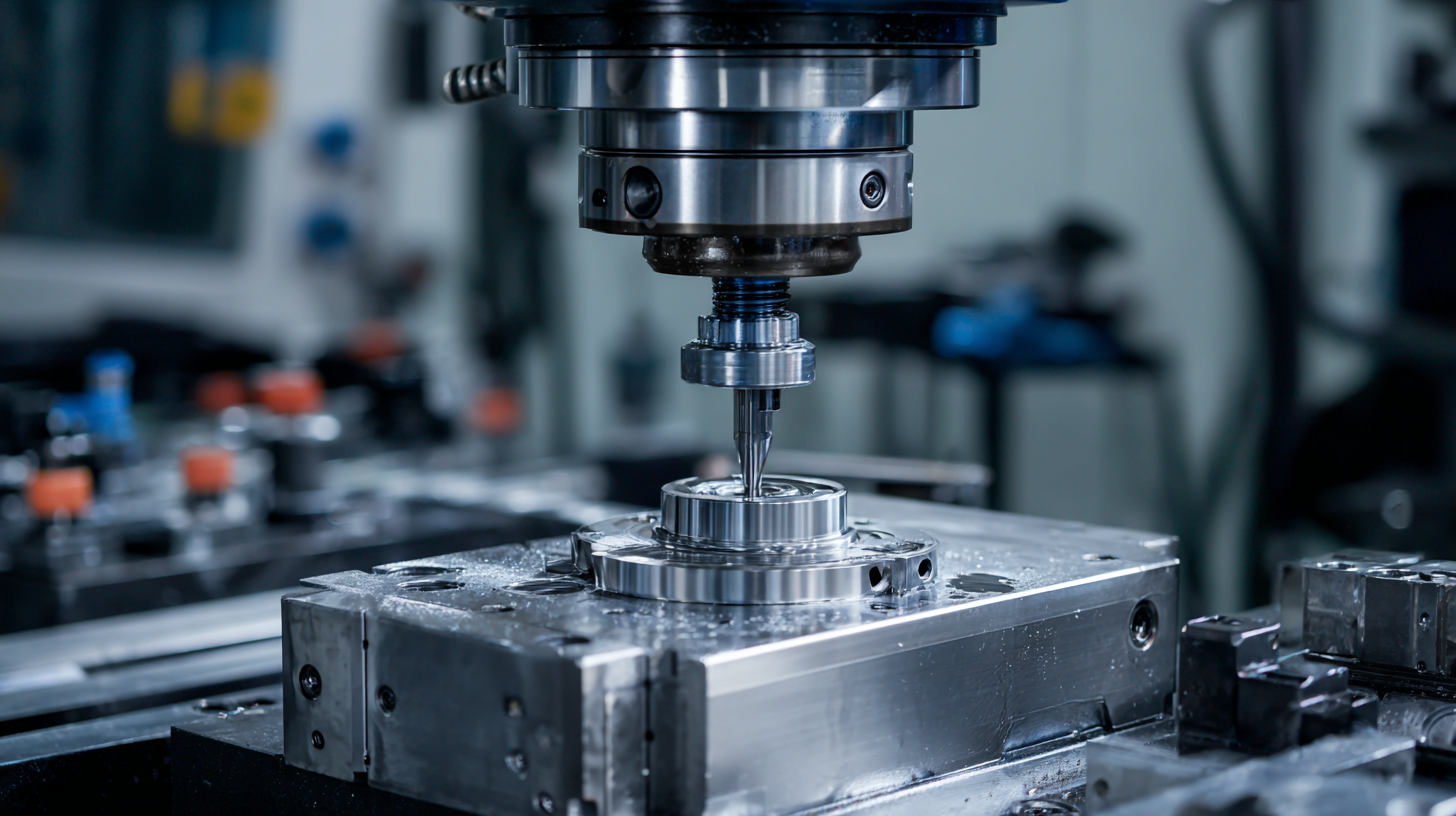

In today's competitive manufacturing landscape, the best grooving machines stand out due to their advanced technology and precision engineering. One of the key features that distinguish these machines is their adaptability to various materials and thicknesses, allowing manufacturers to achieve intricate designs and adjustments quickly. This flexibility means that users can streamline production processes, reducing lead times for a variety of applications ranging from automotive components to precision tooling.

Another essential feature is the integration of automation and smart technology. Many modern grooving machines come equipped with advanced CNC systems that enhance accuracy and repeatability while minimizing human error. This innovation not only improves overall productivity but also allows manufacturers to implement more complex geometries in their designs. Enhanced user interfaces and programmable settings enable operators to easily customize the grooving process, ensuring that they meet the specific requirements of each project efficiently.

| Feature | Description | Benefits |

|---|---|---|

| Automated Control Systems | Advanced software for precise machining and minimal intervention. | Increases accuracy and reduces labor costs. |

| High-Speed Operation | Designed for faster grooving without loss of quality. | Enhances productivity and throughput rate. |

| Versatile Tooling Options | Supports a variety of grooving tools for different materials. | Allows for adaptation to various manufacturing needs. |

| Energy Efficiency | Utilizes energy-saving technologies to reduce consumption. | Lower operational costs and environmental impact. |

| User-Friendly Interface | Intuitive controls and monitoring systems. | Reduces training time and operational errors. |

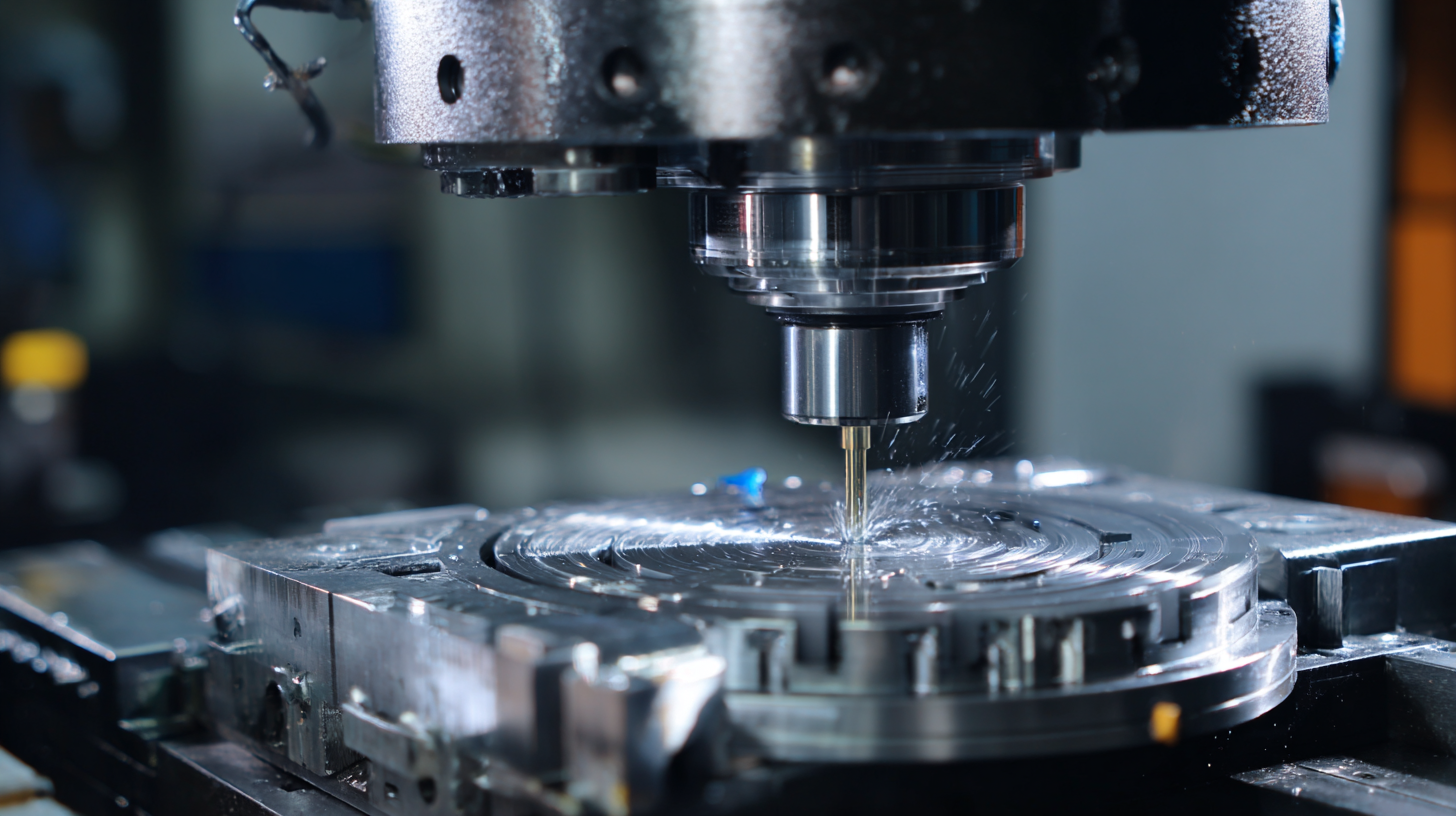

In the realm of modern manufacturing, the implementation of advanced grooving machines has revolutionized production efficiency. These machines utilize innovative techniques that streamline operations, reducing both time and material waste.

By employing CNC (Computer Numerical Control) technology, manufacturers can achieve precision grooving with minimal human intervention, ensuring consistent quality. This automation not only speeds up the grooving process but also enhances the accuracy of each cut, allowing for complex designs that were once labor-intensive to execute.

Moreover, the latest grooving machines are designed with versatility in mind. They accommodate a variety of materials, from metals to composites, enabling manufacturers to adapt quickly to changing demands. Techniques such as wet grooving and high-speed cutting not only improve the lifespan of the tooling but also optimize coolant usage, further contributing to sustainability goals.

By integrating smart technology, these machines can monitor performance in real-time, enabling predictive maintenance that reduces downtime and enhances overall productivity. As a result, grooving machines are not just tools; they are vital components of a modern, efficient manufacturing ecosystem.

In the rapidly evolving landscape of modern manufacturing, the innovative applications of grooving machines have become a game-changer for many Chinese manufacturers. A notable example is a leading automotive parts producer that integrated advanced grooving technology into its production line. By utilizing state-of-the-art grooving machines, the company significantly enhanced the precision of its components while improving productivity. This transformation not only reduced waste but also allowed for quicker turnarounds, enabling them to meet the high demands of the automotive industry.

Another impressive success story comes from a prominent electronics manufacturer that adopted grooving machines to streamline its assembly processes. By employing these machines to create intricate grooves in circuit boards, the company was able to achieve better connectivity and durability in its products. This enhancement resulted in a marked increase in the quality of their electronics, earning them recognition in a competitive market. The effective utilization of grooving machines in these real-world scenarios highlights their pivotal role in driving efficiency and innovation within China's manufacturing sector.

In the fiercely competitive landscape of modern manufacturing, the importance of quality and precision cannot be overstated. Grooving machines have emerged as vital tools that significantly enhance production efficiency and product quality. These machines enable manufacturers to create precise grooves in various materials, allowing for better assembly, reduced waste, and improved overall product performance. The meticulous design and advanced technology behind today's grooving machines ensure that they meet the exact specifications required in a myriad of industries, from aerospace to automotive.

As manufacturers continue to focus on global competitiveness, the strategic implementation of high-quality grooving machines represents a significant advantage. With their ability to execute complex designs with unwavering accuracy, these machines not only streamline production processes but also elevate the end product's quality. This precision leads to fewer defects, reduced rework, and ultimately, a stronger market position. By investing in state-of-the-art grooving technologies, manufacturers can enhance their overall offerings, fostering customer loyalty and driving innovation within the industry.