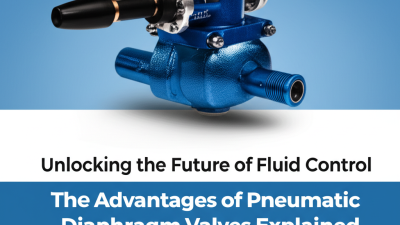

Unlocking the Future of Fluid Control: The Advantages of Pneumatic Diaphragm Valves Explained

In the dynamic landscape of fluid control systems, the pneumatic diaphragm valve has emerged as a pivotal component, offering unparalleled advantages in precision and reliability. According to the Flow Control Industry Report 2023, the market for diaphragm valves is projected to grow at a CAGR of 7.5% over the next five years, fueled by their increasing adoption across various sectors, including pharmaceuticals, food and beverage, and water treatment. The unique design of pneumatic diaphragm valves ensures optimal performance, minimizing leakage and providing efficient flow regulation. By effectively isolating the fluid from the actuating mechanism, these valves enhance safety and extend the lifespan of the system components. Furthermore, their ability to operate with minimal maintenance significantly reduces operational costs, making them a preferred choice for industries demanding high efficiency and compliance with stringent regulatory standards.

As we delve deeper into this topic, we will explore the specific advantages of pneumatic diaphragm valves and how they can revolutionize fluid control solutions for modern applications.

Advantages of Pneumatic Diaphragm Valves in Fluid Control Applications

Pneumatic diaphragm valves are increasingly recognized for their efficiency and reliability in fluid control applications. One of the primary advantages of these valves is their ability to provide precise flow control, making them ideal for industries such as

pharmaceuticals,

food and beverage, and

water treatment. Their design allows for minimal leakage and ensures a tight seal, which is essential when handling sensitive or corrosive fluids.

In addition to their operational efficiency, pneumatic diaphragm valves are relatively easy to maintain. With fewer moving parts compared to traditional valves, maintenance can be completed quickly and with less downtime. This simplicity reduces the likelihood of mechanical failure, ensuring consistent performance over time.

Tips: When selecting pneumatic diaphragm valves for your application, consider factors such as the material compatibility with the fluid being handled and the operating pressure requirements. It's also beneficial to establish a regular maintenance schedule to prolong the life of the valves and enhance their performance. By keeping these considerations in mind, you can optimize the advantages of pneumatic diaphragm valves in your fluid control systems.

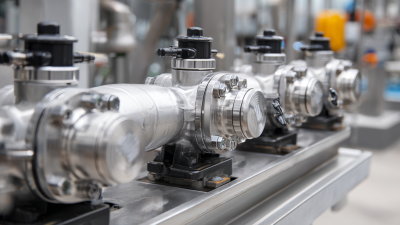

Key Performance Metrics: Flow Rate, Pressure, and Temperature Tolerance

Pneumatic diaphragm valves are increasingly recognized for their exceptional performance in fluid control applications, particularly when it comes to critical metrics such as flow rate, pressure, and temperature tolerance. The flow rate is essential in determining the efficiency of fluid transport; these valves are designed with high precision to ensure optimal flow control, minimizing turbulence and maximizing throughput. Their ability to maintain a consistent flow under varying operational conditions is a significant advantage, enabling industries to meet stringent production requirements without compromising quality.

In terms of pressure tolerance, pneumatic diaphragm valves excel as they can handle a wide range of pressures, which makes them suitable for diverse applications, from pharmaceuticals to petrochemicals. Their design minimizes the risk of leaks and ensures reliability even in high-pressure systems. Moreover, temperature tolerance is another critical metric, as these valves can function effectively in extreme temperature environments. This adaptability allows them to perform under various conditions without losing integrity, ensuring safe and efficient fluid control. With these key performance metrics, pneumatic diaphragm valves are poised to play a pivotal role in the future of fluid management systems.

Unlocking the Future of Fluid Control: Key Performance Metrics of Pneumatic Diaphragm Valves

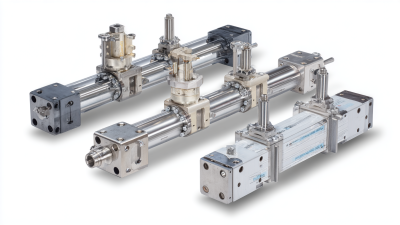

Market Growth Trends: The Rising Demand for Pneumatic Valves in Various Industries

The global market for pneumatic valves is witnessing significant growth across various industries, driven by the increasing demand for advanced fluid control solutions.

As industries expand and modernize, the adoption of pneumatic diaphragm valves is on the rise due to their efficiency and reliability. By 2026, the pneumatic components market is expected to exceed

$16.57 billion, with a compound annual growth rate (CAGR) of over 5.3% through the next decade. This trend indicates a robust interest in systems

that enhance automation and streamline operations.

Furthermore, the air suspension valve block market is anticipated to grow substantially, driven by innovations in vehicle design and performance enhancements. With applications ranging

from trucks to buses, the need for effective pneumatic controls is evident as manufacturers prioritize safety and comfort in their products. This trend towards pneumatic technologies reflects a broader shift towards more sophisticated

and efficient systems, positioning pneumatic valves as essential components in the future of industrial fluid control.

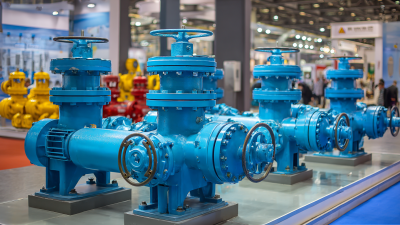

Cost-Effectiveness Analysis: Long-term Savings with Pneumatic vs. Traditional Valves

When considering the cost-effectiveness of fluid control systems,

pneumatic diaphragm valves present a compelling case compared to traditional valve options.

The initial investment for pneumatic valves may be slightly higher, but their longevity and reduced maintenance requirements lead to significant long-term savings.

Pneumatic diaphragm valves are designed to minimize wear and tear, thanks to their simple and effective construction,

which reduces the frequency of replacements.

Moreover, the operational efficiency of pneumatic diaphragm valves leads to lower energy consumption.

These valves can respond more quickly and accurately to control signals, enhancing system performance.

The reduced downtime due to failures or maintenance interruptions also contributes to overall savings.

In industries where uptime is crucial, the reliability of pneumatic diaphragm valves can translate to increased productivity and profitability,

making them a wise choice for companies looking to optimize their fluid control solutions.

Environmental Impact: Benefits of Pneumatic Diaphragm Valves for Sustainable Operations

Pneumatic diaphragm valves are increasingly being recognized for their role in promoting sustainable operations across various industries. These valves are designed to control the flow of fluids with precision while minimizing environmental impact. By utilizing compressed air for actuation, they significantly reduce energy consumption compared to electric alternatives, making them a more eco-friendly choice. Additionally, their robust design tends to result in longer service lives, which translates to less waste and fewer replacements over time.

**Tips:** When selecting pneumatic diaphragm valves, consider those with adjustable flow rates and pressure settings to optimize efficiency. Regular maintenance can further enhance their lifespan and performance, contributing to a sustainable operation.

The use of pneumatic diaphragm valves also aids in preventing leaks and reducing emissions. Their unique construction minimizes potential fallout from fluid handling, protecting both the environment and plant personnel. By integrating these valves into your fluid control systems, you're not just investing in advanced technology—you're also taking a significant step toward greener, more responsible operations.

**Tips:** Always evaluate the materials used in the valves to ensure they are compatible with your specific applications, which helps prevent chemical reactions and extends valve integrity, thus supporting sustainability efforts.