Exploring the Benefits of Pneumatic Diaphragm Valves in Industrial Applications: A Comprehensive Guide

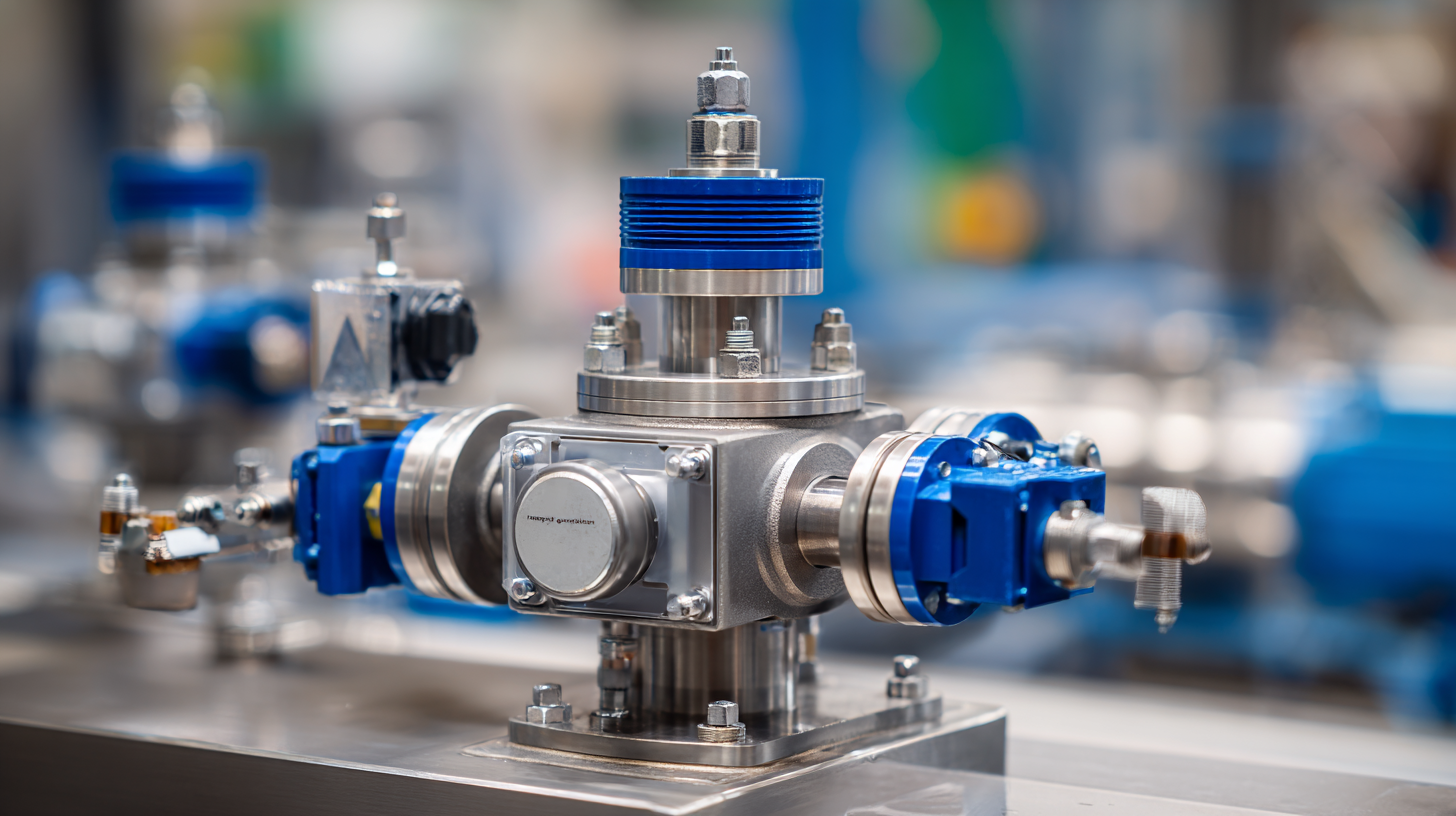

In the rapidly evolving landscape of industrial applications, the pneumatic diaphragm valve has emerged as a critical component, renowned for its reliability and efficiency in fluid control systems.

According to a recent report by MarketsandMarkets, the global market for diaphragm valves is projected to grow from USD 4.0 billion in 2021 to USD 5.5 billion by 2026, highlighting the increasing adoption of advanced valve technologies across various sectors, including pharmaceuticals and chemical processing.

The advantages of pneumatic diaphragm valves, such as their exceptional sealing capabilities and responsiveness to changes in pressure, make them particularly suitable for handling corrosive and viscous fluids.

This comprehensive guide will delve into the multifaceted benefits of pneumatic diaphragm valves, providing industry professionals with essential insights and practical tips for optimizing their industrial applications.

As the demand for higher performance and safety standards continues to rise, understanding the role of these valves becomes imperative for maintaining operational excellence and efficiency.

Benefits of Pneumatic Diaphragm Valves for Process Control Efficiency in Industries

Pneumatic diaphragm valves have become essential in various industrial applications due to their efficiency in process control. These valves offer unparalleled precision and reliability in regulating flow, making them a preferred choice for industries such as pharmaceuticals, food processing, and chemicals. By utilizing compressed air, they provide rapid response times and enhanced control over the flow rate, which is crucial for maintaining product quality and safety.

Tips: When selecting pneumatic diaphragm valves for your processes, consider factors such as the fluid type, pressure requirements, and the valve materials to ensure compatibility and optimal performance. Proper sizing is also vital; a valve that is too small may restrict flow, while an oversized valve can lead to efficiency losses and increased costs.

Furthermore, pneumatic diaphragm valves are designed for easy maintenance and operation. Their simple construction allows for quick diagnostics and repairs, reducing downtime in production. This reliability translates into higher process efficiency and lowers operational risks, ultimately contributing to enhanced productivity across various sectors.

Exploring the Benefits of Pneumatic Diaphragm Valves in Industrial Applications

| Feature |

Description |

Benefits |

| Material Compatibility |

Can handle a wide range of fluids including corrosive and viscous materials. |

Reduces the risk of leaks and extends the lifespan of the valve. |

| Corrosion Resistance |

Constructed with materials that resist chemical corrosion. |

Minimizes maintenance costs and downtime. |

| Precision Control |

Allows for accurate flow and pressure control in processes. |

Improves overall process efficiency and product quality. |

| Quick Operation |

Utilizes pneumatic actuation for rapid opening and closing. |

Enhances responsiveness to changing process conditions. |

| Low Maintenance |

Fewer moving parts lead to reduced wear and tear. |

Lowers total cost of ownership over time. |

Cost Savings Through Reduced Maintenance Needs for Pneumatic Diaphragm Valves

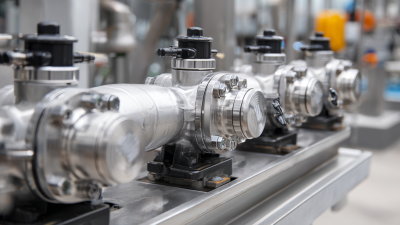

Pneumatic diaphragm valves have gained significant attention in various industrial applications due to their reliable performance and efficiency. One of the most compelling benefits highlighted by recent studies is their potential for cost savings through reduced maintenance needs. According to a report by the International Society of Automation, improper maintenance can lead to downtime costs averaging $20,000 per hour in a manufacturing environment. Pneumatic diaphragm valves, designed with fewer moving parts, minimize wear and tear, resulting in a 30% reduction in maintenance requirements compared to traditional valve systems.

Additionally, the reduced maintenance needs of pneumatic diaphragm valves contribute to longer lifespans and lower operational costs. A 2022 research survey conducted by the American Society of Mechanical Engineers (ASME) found that facilities utilizing these valves reported a 25% decrease in parts replacement frequency, significantly decreasing overall maintenance budgets. The use of these valves allows industries to not only enhance reliability but also redirect funds that would typically be allocated for maintenance towards more productive areas, such as innovation and expansion. As industries continue to seek ways to optimize operational efficiency, pneumatic diaphragm valves stand out as a strategic investment.

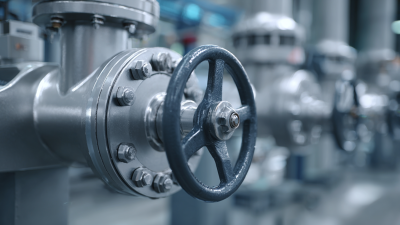

Improved Safety Features of Pneumatic Diaphragm Valves in Hazardous Environments

Pneumatic diaphragm valves are increasingly recognized for their improved safety features, making them a preferred choice in hazardous industrial environments. According to a report by MarketsandMarkets, the global demand for pneumatic valves is projected to grow significantly, driven by the need for enhanced safety measures in industries dealing with corrosive or high-pressure fluids. The unique design of diaphragm valves minimizes leakage, reducing the risk of exposure to hazardous materials, which aligns with OSHA standards for workplace safety.

In environments where fluid containment is critical, pneumatic diaphragm valves provide additional benefits through their robust construction and ease of maintenance. A study published in the Journal of Materials Processing Technology highlights that the use of elastomeric diaphragms can sustain extreme temperatures and pressures, further preventing catastrophic failures. Additionally, the Actuator Performance report by the International Society of Automation indicates that pneumatic actuators offer rapid response times, ensuring that valves can be shut off quickly in emergency situations, thereby protecting personnel and equipment alike. Overall, the integration of pneumatic diaphragm valves into industrial systems not only boosts operational efficiency but also plays a pivotal role in safeguarding against potential hazards.

Benefits of Pneumatic Diaphragm Valves in Industrial Applications

This chart illustrates the various benefits of pneumatic diaphragm valves in industrial applications, with emphasis on safety features, durability, maintenance, flow control, and cost efficiency. Each benefit is rated on a scale from 1 to 10, showcasing their significance in hazardous environments.

Enhanced Flow Control Precision: Statistical Insights on Pneumatic Diaphragm Valves

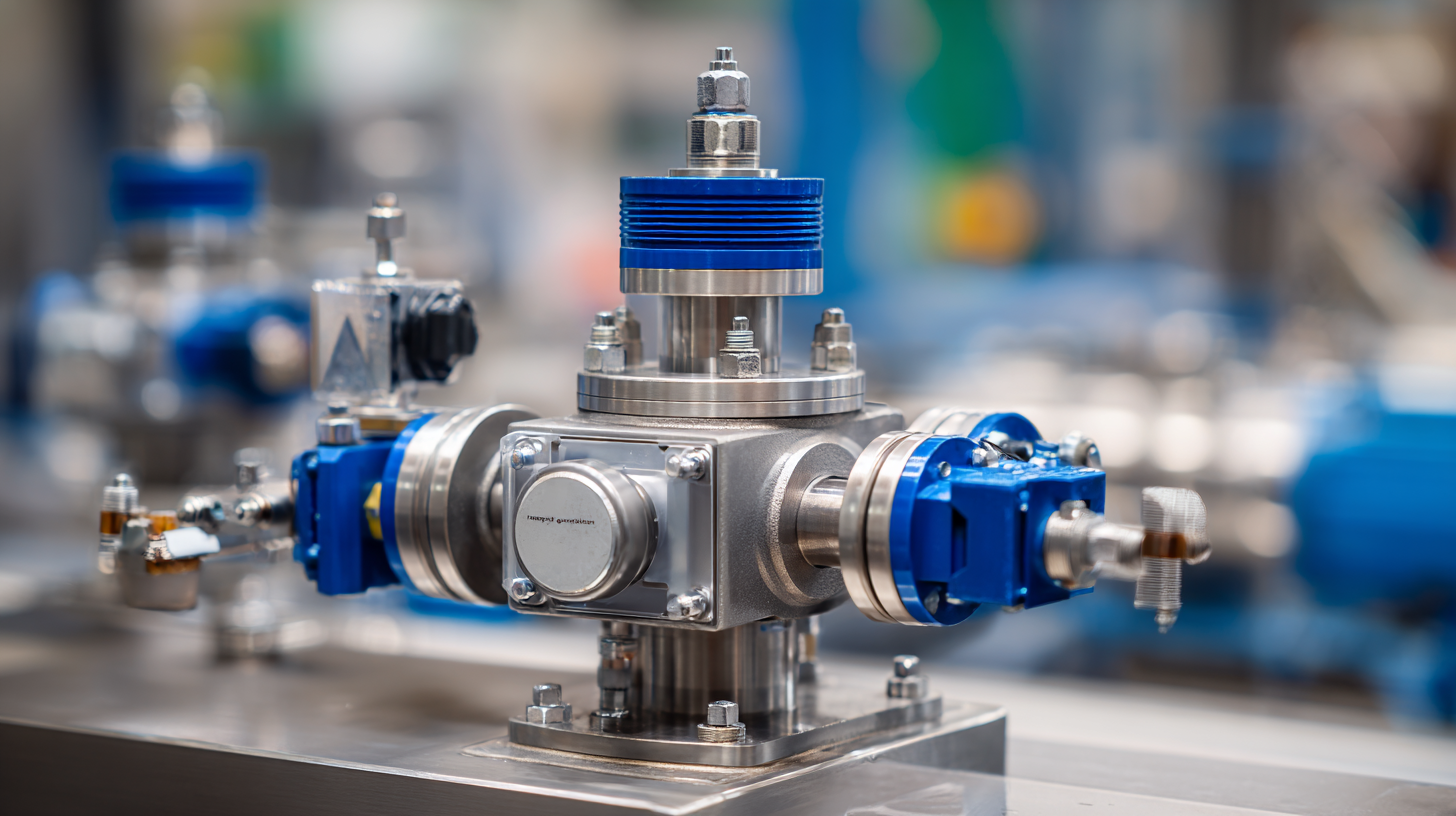

Pneumatic diaphragm valves have emerged as a pivotal component in various industrial sectors, offering enhanced flow control precision that is evidenced by statistical insights. These valves are particularly favored for their ability to regulate fluid flow with a high degree of accuracy, which is crucial in processes where even minor fluctuations can lead to suboptimal performance or safety hazards.

The diaphragm serves as a flexible barrier that adjusts to pressure changes, ensuring that flow rates are maintained within specified parameters.

Recent studies highlight that pneumatic diaphragm valves can achieve flow control accuracy levels exceeding 95%. This level of precision is beneficial in applications such as pharmaceutical manufacturing, food processing, and chemical production, where exact flow rates significantly impact product quality and regulatory compliance. Furthermore, the statistical data indicates that these valves experience lower wear and tear over time, resulting in reduced maintenance costs and increased reliability. This combination of durability and precision positions pneumatic diaphragm valves as an essential element in modern industrial systems, underscoring their value in optimizing operational efficiency.

Industry-Specific Applications of Pneumatic Diaphragm Valves: Case Studies and Data Analysis

Pneumatic diaphragm valves are essential components in various industrial applications, offering numerous advantages such as precise flow control, reliability, and ease of maintenance. In the pharmaceutical industry, for instance, these valves play a critical role in ensuring the sterile handling of liquids and gases. Case studies have shown that their design minimizes dead volume, reducing the risk of contamination. Data analysis from leading pharmaceutical manufacturers indicates that the implementation of pneumatic diaphragm valves has resulted in significant improvements in process efficiency and product safety.

In the food and beverage sector, pneumatic diaphragm valves contribute to both hygiene and operational effectiveness. These valves can be easily cleaned and sanitized, making them ideal for applications where strict sanitary standards are enforced. For example, a beverage manufacturer reported a 30% reduction in downtime related to valve maintenance after integrating these valves into their production lines. Furthermore, data collected from various processing plants demonstrates that pneumatic diaphragm valves can operate effectively across a wide range of temperatures and pressures, solidifying their position as a versatile solution for industry-specific challenges.