In recent years, the cutting machine industry has witnessed remarkable advancements, particularly in China, which has emerged as a key player in the global market. According to a recent report by MarketsandMarkets, the cutting machine market is projected to reach USD 6.8 billion by 2025, growing at a CAGR of 5.1% from 2020 to 2025. This growth is largely driven by the rising demand for precision and efficiency in manufacturing processes across various sectors, including automotive, aerospace, and textiles. As manufacturers increasingly adopt automation and smart technologies, China's commitment to precision engineering ensures that its cutting machines are not only high in quality but also competitively priced. This blog will explore the meticulous craftsmanship involved in producing cutting machines in China, highlighting their significance in meeting the demands of a rapidly evolving global landscape.

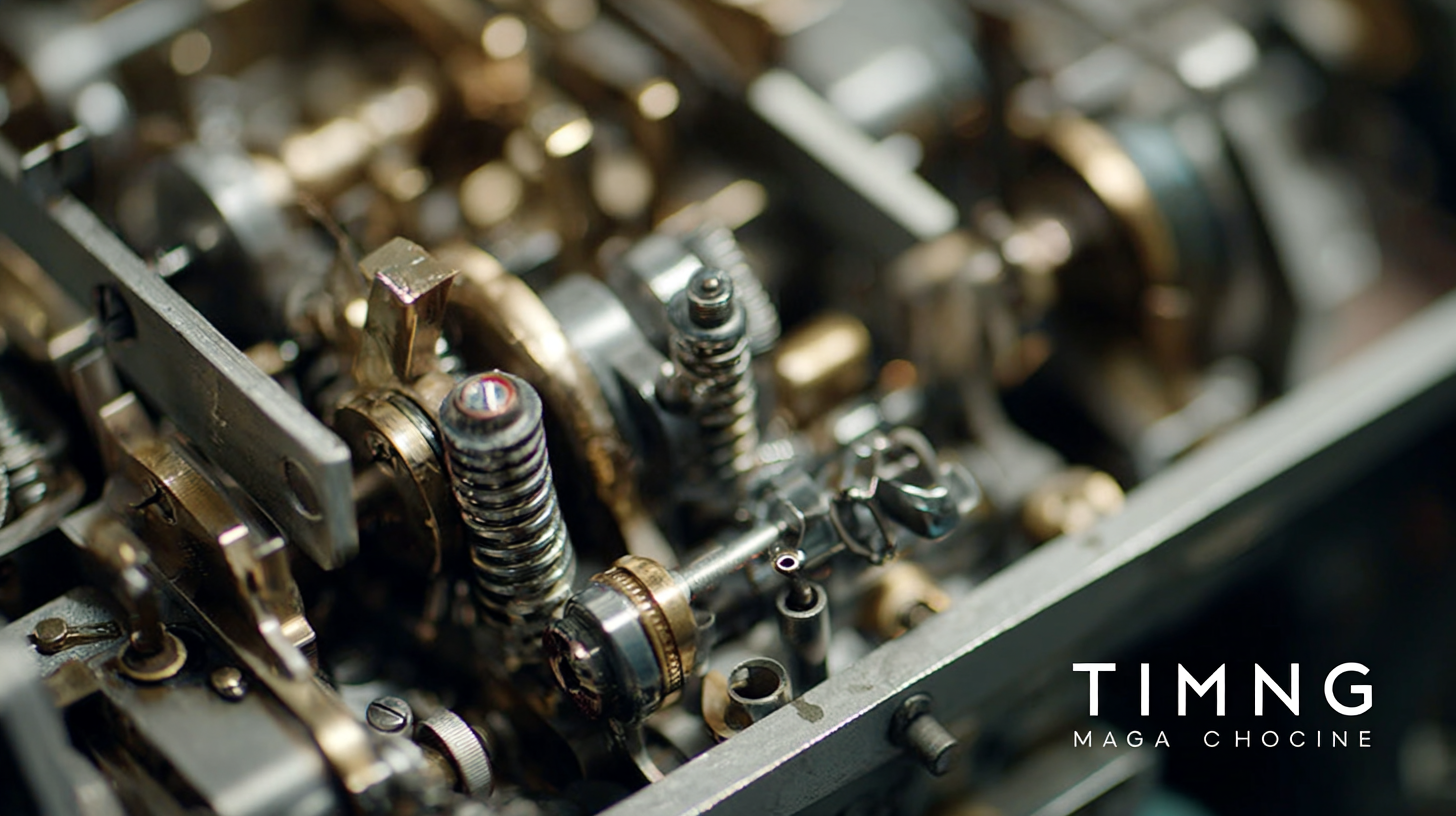

The evolution of precision engineering in China has been marked by significant advancements that reflect a rich historical context. From its early days, when craftsmanship relied on manual precision, to today’s automated and digitally controlled processes, China's journey in this field mirrors the global evolution of mechanical engineering. Notably, innovations in precision engineering have allowed Chinese manufacturers to enhance their competitiveness in the global market, shifting from mere imitation to original design and innovation.

As we look at the current landscape, it's evident that China's universities and domestic companies have become vital players in fostering innovation. This transition has been fueled by a robust focus on research and development, leading to a new wave of smart manufacturing practices. The integration of advanced technologies and artificial intelligence into precision engineering not only enhances operational efficiency but also sets the stage for groundbreaking advancements in various industries, positioning China as a leader in the global marketplace for cutting machines and beyond.

Precision engineering in China is transforming the cutting machine industry, positioning it as a dominant player in the global market. Key technologies such as artificial intelligence (AI), the Internet of Things (IoT), and machine learning are driving innovation in this sector. Reports suggest that as of 2023, Chinese firms are responsible for nearly two-thirds of global advancements in precision cutting equipment, emphasizing their vital role in meeting the increasing demand for high-precision manufacturing processes worldwide.

Advanced technologies are not merely enhancing machine capabilities but are fundamentally altering supply chain dynamics. For instance, the application of AI in manufacturing has resulted in a productivity increase of approximately 30%, showcasing how these innovative solutions optimize operational efficiencies. Moreover, China’s commitment to integrating blockchain and clean energy innovations into cutting processes is enabling companies to achieve greater transparency and sustainability, traits increasingly valued in today’s market. As a result, the landscape of cutting machine technologies is rapidly evolving, marking China's significant contribution to global manufacturing excellence.

| Category | Technology | Application | Advantages |

|---|---|---|---|

| CNC Machines | Digital Control Systems | Complex Geometric Machining | High Precision, Flexibility |

| Laser Cutting | Fiber Laser Technology | Metal Sheets Processing | Clean Cuts, Minimal Waste |

| Plasma Cutting | High-Frequency Arc Technology | Thick Metal Fabrication | Speed, Economical for Thick Cuts |

| Water Jet Cutting | Ultra-High Pressure Systems | Delicate Materials Cutting | No Heat Affected Zone, Versatility |

| EDM Machines | Sparking Technology | Complex Shapes in Hard Materials | Precision, Intricate Designs |

Quality control is a critical aspect in the manufacturing of cutting machines, especially as the global demand for precision engineering continues to rise. According to a report by Mordor Intelligence, the global cutting machine market is expected to grow at a CAGR of 6.8% from 2021 to 2026, driven by an increasing need for high-quality manufacturing processes. In this competitive landscape, manufacturers in China are implementing rigorous quality control measures to ensure their machines meet international standards.

One effective strategy employed by Chinese manufacturers is the adoption of advanced testing technologies. For instance, the use of laser interferometers and coordinate measuring machines (CMM) allows manufacturers to achieve tighter tolerances, significantly enhancing the accuracy and reliability of their cutting machines. A report from MarketsandMarkets indicates that quality assurance in manufacturing can reduce production costs by up to 20% while improving product lifespan. Additionally, integrating real-time data analytics into the production line has facilitated early detection of defects, further bolstering product quality.

Furthermore, certification from international standards organizations, such as ISO 9001, plays a crucial role in assuring customers of the quality of cutting machines. Manufacturers that prioritize compliance with these standards not only improve their operational efficiencies but also enhance their credibility in the global market. As the industry evolves, maintaining stringent quality control is paramount for Chinese manufacturers aiming to position themselves as leaders in precision engineering on the world stage.

The global market for precision cutting equipment is experiencing significant growth, driven by advancements in technology and increasing demands across various industries. In 2018, the global grinding machine market was valued at approximately $4.72 billion and is projected to reach $9.01 billion by 2032, reflecting a compound annual growth rate (CAGR) of 4.4%. This upward trend highlights the increasing reliance on precision machinery for manufacturing processes in sectors such as automotive, aerospace, and general engineering.

In parallel, the CNC machines market is set for remarkable expansion, with expectations to grow from $101.22 billion in 2025 to $195.59 billion by 2032, demonstrating a robust CAGR of 9.9%. The lathe machine market follows suit, projected to increase from $25.01 billion in 2018 to around $57.54 billion by 2032, with a steady growth rate of 5.6%. Additionally, the laser cutting machine segment is anticipated to see an impressive CAGR of 9.21% from 2023, indicating a growing preference for high-precision cutting techniques. This momentum underscores the critical role of precision engineering in meeting the global demands for cutting-edge manufacturing solutions.

The future of cutting machines in China lies at the intersection of sustainability and smart technology. As global markets strive for efficiency and eco-friendliness, manufacturers are increasingly focusing on creating machines that not only enhance precision but also reduce environmental impact. Innovations in materials and energy-efficient designs are becoming paramount, with a strong emphasis on minimizing waste during the cutting processes.

Tips for integrating sustainability into cutting machine design include exploring biodegradable materials and energy-efficient motors. Additionally, incorporating smart technology such as IoT-enabled sensors can optimize operation in real time, leading to significant energy savings and the ability to track performance metrics for continuous improvement. This approach not only aligns with global sustainability goals but also positions manufacturers to meet the evolving demands of international clients seeking greener solutions.

Embracing these future directions, China’s cutting machine manufacturers can leverage advancements in smart technologies—enhancing automation and predictive maintenance features, thereby elevating operational efficiency. As the industry evolves, it's essential to prioritize the integration of these innovative technologies to remain competitive in the global landscape while upholding environmental standards.