The Critical Role of Process Valves in Enhancing Industrial Efficiency and Safety

Process valves play an indispensable role in enhancing industrial efficiency and safety across various sectors, including oil and gas, pharmaceuticals, and food processing. According to a report by Research and Markets, the global market for industrial valves is projected to reach $105 billion by 2025, driven by increasing infrastructure investments and the need for efficient fluid control systems.

Process valves, specifically designed to regulate, control, and direct the flow of liquids and gases, contribute significantly to operational reliability and safety measures. Recent data from the International Society of Automation highlights that improper valve management can lead to equipment failures, resulting in costly downtime, estimated at up to $30 billion annually in the U.S. alone.

Thus, emphasizing the critical importance of process valves is essential not only for meeting production demands but also for ensuring compliance with stringent safety regulations, ultimately fostering a more sustainable industrial environment.

Understanding Process Valves: Types and Functions in Industry

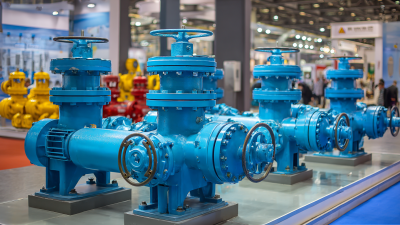

Process valves are integral components in various industrial applications, playing a pivotal role in controlling the flow of fluids and gases. These valves come in several types, each designed to perform specific functions, such as isolation, regulation, and safety. According to a report by MarketsandMarkets, the global industrial valves market is expected to reach $80.36 billion by 2025, reflecting the growing emphasis on efficient fluid management. Gate valves, globe valves, and ball valves are among the most common types used across different sectors, including oil and gas, water treatment, and chemical processing.

Process valves are integral components in various industrial applications, playing a pivotal role in controlling the flow of fluids and gases. These valves come in several types, each designed to perform specific functions, such as isolation, regulation, and safety. According to a report by MarketsandMarkets, the global industrial valves market is expected to reach $80.36 billion by 2025, reflecting the growing emphasis on efficient fluid management. Gate valves, globe valves, and ball valves are among the most common types used across different sectors, including oil and gas, water treatment, and chemical processing.

The functionality of process valves extends beyond mere flow control; they also enhance operational safety and efficiency. For instance, the American National Standards Institute (ANSI) estimates that employing the right valve can reduce fluid leakage by up to 20%, significantly lowering the risk of environmental hazards and product loss. Additionally, advancements in actuator and control technologies have enabled more precise valve operation, contributing to a more streamlined manufacturing process. As industries strive to optimize performance and comply with stringent regulations, understanding the various types of process valves and their specific functions becomes essential for enhancing productivity and safety.

Key Considerations for Selecting Process Valves for Efficiency

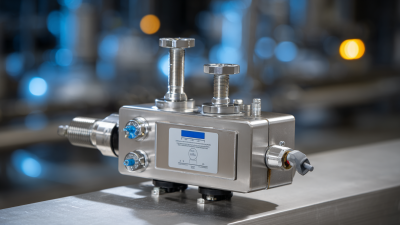

When selecting process valves for industrial applications, efficiency and safety should be prioritized. The pharmaceutical industry, in particular, requires valves that not only meet stringent regulatory standards but also enhance workflow performance. Recent forecasts indicate that the market for diaphragm valves in pharmaceutical processes will see substantial growth, expected to reach a value of $284.6 million by 2032, with a compound annual growth rate of 11.02% through 2024. This underscores the importance of choosing the right valves to ensure process integrity and operational efficiency.

Key considerations in selecting process valves include material compatibility, pressure ratings, and the valve's ability to maintain hygiene and prevent contamination. Valves made from materials that withstand aggressive chemicals are crucial in ensuring reliability and prolonging service life. Furthermore, features such as automated controls and feedback systems can significantly enhance operational efficiency while maintaining safety standards. As industrial sectors evolve, the importance of integrating advanced valve technologies cannot be overstated, as they play a vital role in enhancing overall performance and safety in manufacturing processes.

The Critical Role of Process Valves in Enhancing Industrial Efficiency and Safety

| Valve Type |

Application Area |

Efficiency Benefits |

Safety Features |

Key Considerations |

| Gate Valve |

Water Supply |

Low-pressure drop |

Manual operation locks |

Size and pressure rating |

| Ball Valve |

Oil and Gas |

Quick operation, tight seal |

Emergency shut-off |

Material compatibility |

| Butterfly Valve |

HVAC systems |

Space-saving, lightweight |

Position indication |

Operating torque |

| Check Valve |

Pipelines |

Prevents backflow |

Fail-safe design |

Flow direction |

| Globe Valve |

Steam lines |

Good throttling capability |

Built-in pressure relief |

Flow capacity |

Best Practices for Maintaining Process Valves to Enhance Safety

Maintaining process valves is crucial for optimizing both safety and efficiency in industrial operations. Regular inspection and preventive maintenance are essential practices that help identify potential issues before they escalate. This includes checking for wear, leaks, and proper operation under varying pressure and temperature conditions. Implementing a routine maintenance schedule ensures that valves perform at peak efficiency, thereby reducing the likelihood of unexpected failures that can lead to costly downtimes and safety hazards.

Another best practice is the use of proper lubrication and sealing techniques. Over time, the internal components of process valves can wear out or become contaminated, which can impair their functionality. By employing the correct lubricants and regularly replacing seals, industries can extend the lifespan of their valves. Additionally, training personnel on the importance of valve maintenance and providing them with the necessary tools increases awareness and responsibility, leading to safer and more efficient operations. Regular audits and documentation of maintenance activities also play a vital role in fostering a culture of safety and continuous improvement.

Integrating Process Valves into Automated Systems for Optimal Performance

Integrating process valves into automated systems is essential for achieving optimal performance in industrial operations. These valves serve as the critical control points within a process, allowing for precise regulation of flow, pressure, and temperature. When automated, these valves enhance operational efficiency by minimizing manual intervention and the potential for human error. Advanced control systems can seamlessly adjust the valve positions in real-time, responding to fluctuating process conditions, which leads to improved consistency and superior product quality.

Moreover, the integration of smart process valves into automated frameworks not only raises productivity but also bolsters safety in industrial environments. Automated systems can incorporate various sensors that monitor the status and performance of valves, providing instant feedback and alerts for any anomalies. This capability allows for proactive maintenance and reduces the risk of failures that could lead to unsafe situations. By enhancing the responsiveness and reliability of process valves through automation, industries can significantly mitigate risks and ensure a safer working environment while optimizing their overall operations.

Evaluating the Impact of Process Valves on Overall Industrial Operations

Process valves play a pivotal role in optimizing industrial operations, influencing efficiency and safety across various sectors. According to a report by the International Society of Automation, approximately 35% of industrial downtime can be attributed to valve-related issues, highlighting the need for reliable valve performance. By ensuring that process valves operate seamlessly, industries can significantly reduce this downtime and enhance productivity. For instance, in chemical manufacturing, where precise flow control is critical, high-quality valves can lead to a 15% increase in operational efficiency, as noted in a study published in the Journal of Process Control.

Moreover, the adoption of advanced valve technologies, such as smart valves equipped with IoT capabilities, can further improve operational oversight. The Global Market Insights report indicates that the smart valve market is projected to surpass $3 billion by 2026, driven by the demand for increased automation and real-time data analytics. This transition not only streamlines manufacturing processes but also enhances safety by enabling predictive maintenance, which can lower incident rates by up to 20%. Such improvements in valve technology significantly contribute to the overall resilience and safety of industrial operations, marking a crucial step toward more efficient and secure manufacturing environments.

The Impact of Process Valves on Industrial Efficiency and Safety

This chart illustrates the key performance metrics influenced by the use of process valves in industrial operations. The data reflects how process valves enhance operational efficiency while minimizing safety incidents, maintenance costs, downtime, and energy consumption.

Process valves are integral components in various industrial applications, playing a pivotal role in controlling the flow of fluids and gases. These valves come in several types, each designed to perform specific functions, such as isolation, regulation, and safety. According to a report by MarketsandMarkets, the global industrial valves market is expected to reach $80.36 billion by 2025, reflecting the growing emphasis on efficient fluid management. Gate valves, globe valves, and ball valves are among the most common types used across different sectors, including oil and gas, water treatment, and chemical processing.

Process valves are integral components in various industrial applications, playing a pivotal role in controlling the flow of fluids and gases. These valves come in several types, each designed to perform specific functions, such as isolation, regulation, and safety. According to a report by MarketsandMarkets, the global industrial valves market is expected to reach $80.36 billion by 2025, reflecting the growing emphasis on efficient fluid management. Gate valves, globe valves, and ball valves are among the most common types used across different sectors, including oil and gas, water treatment, and chemical processing.