Understanding the Role of Straight Valves in Modern Industrial Applications

In modern industrial applications, the significance of straight valves cannot be overstated, as they play a crucial role in fluid control and system regulation. According to a report by MarketsandMarkets, the global valve market is expected to grow from $72.7 billion in 2021 to $90.2 billion by 2026, with straight valves being a vital component due to their ability to minimize fluid turbulence and pressure loss. These valves are essential in various sectors, including oil and gas, water treatment, and chemical processing, where efficiency and reliability are paramount. As industries face increasing demands for performance optimization and energy conservation, the use of straight valves is becoming increasingly prominent.

This guide aims to provide a comprehensive understanding of the types, advantages, and applications of straight valves in contemporary industrial settings, ensuring that operators can leverage their capabilities effectively.

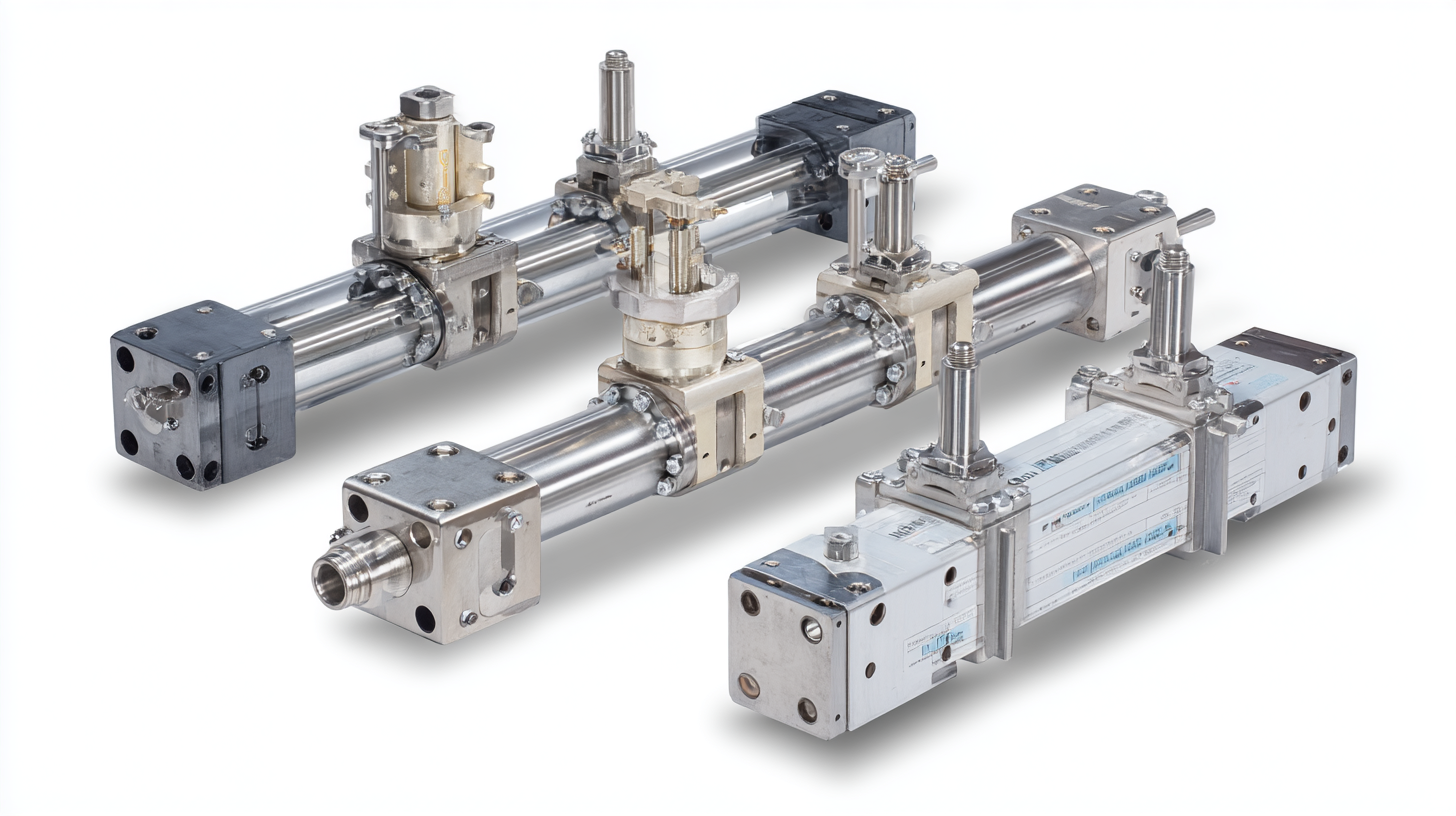

The Functionality of Straight Valves in Various Industrial Processes

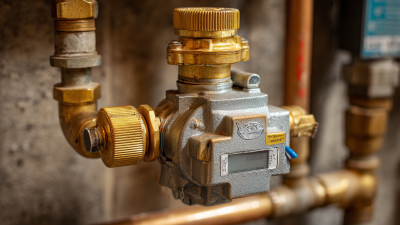

Straight valves play a pivotal role in numerous industrial processes, facilitating the smooth flow of liquids and gases. These valves are engineered to allow fluid to pass through a straight path, minimizing pressure loss and optimizing flow efficiency. According to the "Global Valve Market" report by ResearchAndMarkets, the straight valve segment is projected to grow at a CAGR of 5.1% from 2023 to 2028, underlining the increasing demand for reliable and efficient flow control in industries such as oil and gas, water treatment, and power generation.

In the chemical processing industry, straight valves are crucial for maintaining process integrity and safety. Their design reduces turbulence, which is essential for chemical reactions that require precise conditions. As indicated in a 2022 study by Market Research Future, the enhanced performance of straight valves can lead to a reduction in operational costs by as much as 25%, as facilities can ensure optimal flow rates without excessive energy expenditure. Furthermore, straight valves are typically easier to maintain and install, making them an attractive choice for facilities looking to optimize their operational efficiency.

Key Industries Utilizing Straight Valves: A Market Overview

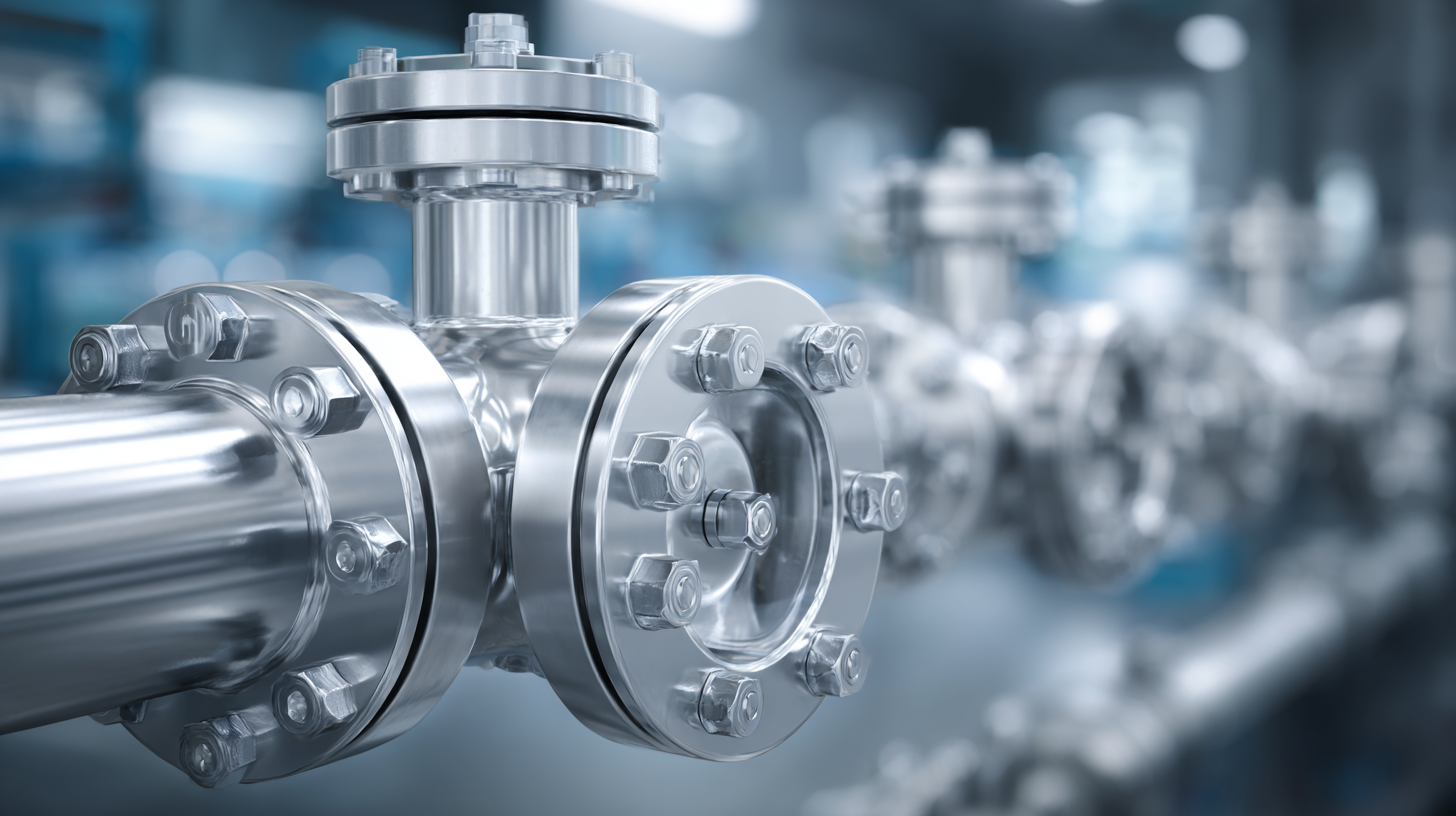

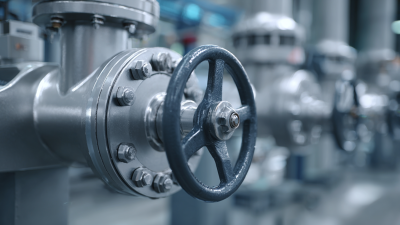

Straight valves play a crucial role in various industrial applications, serving as essential components in fluid control systems. Key industries utilizing straight valves include oil and gas, water treatment, and chemical manufacturing. In the oil and gas sector, these valves are vital for regulating flow in pipelines and ensuring the safe transport of hydrocarbons. Their ability to maintain consistent flow rates while minimizing pressure drops makes them indispensable for both upstream and downstream operations.

Straight valves play a crucial role in various industrial applications, serving as essential components in fluid control systems. Key industries utilizing straight valves include oil and gas, water treatment, and chemical manufacturing. In the oil and gas sector, these valves are vital for regulating flow in pipelines and ensuring the safe transport of hydrocarbons. Their ability to maintain consistent flow rates while minimizing pressure drops makes them indispensable for both upstream and downstream operations.

In water treatment plants, straight valves facilitate the movement of water through treatment processes, ensuring efficient regulation of flow rates. They are also used in agricultural applications, where they help manage irrigation systems and optimize water distribution. The chemical manufacturing industry relies on straight valves to control complex reactions and fluid transfers safely. As industries continue to advance and innovate, the demand for reliable straight valves is expected to grow, highlighting their significance in modern industrial applications.

Performance Metrics: Efficiency and Reliability of Straight Valves

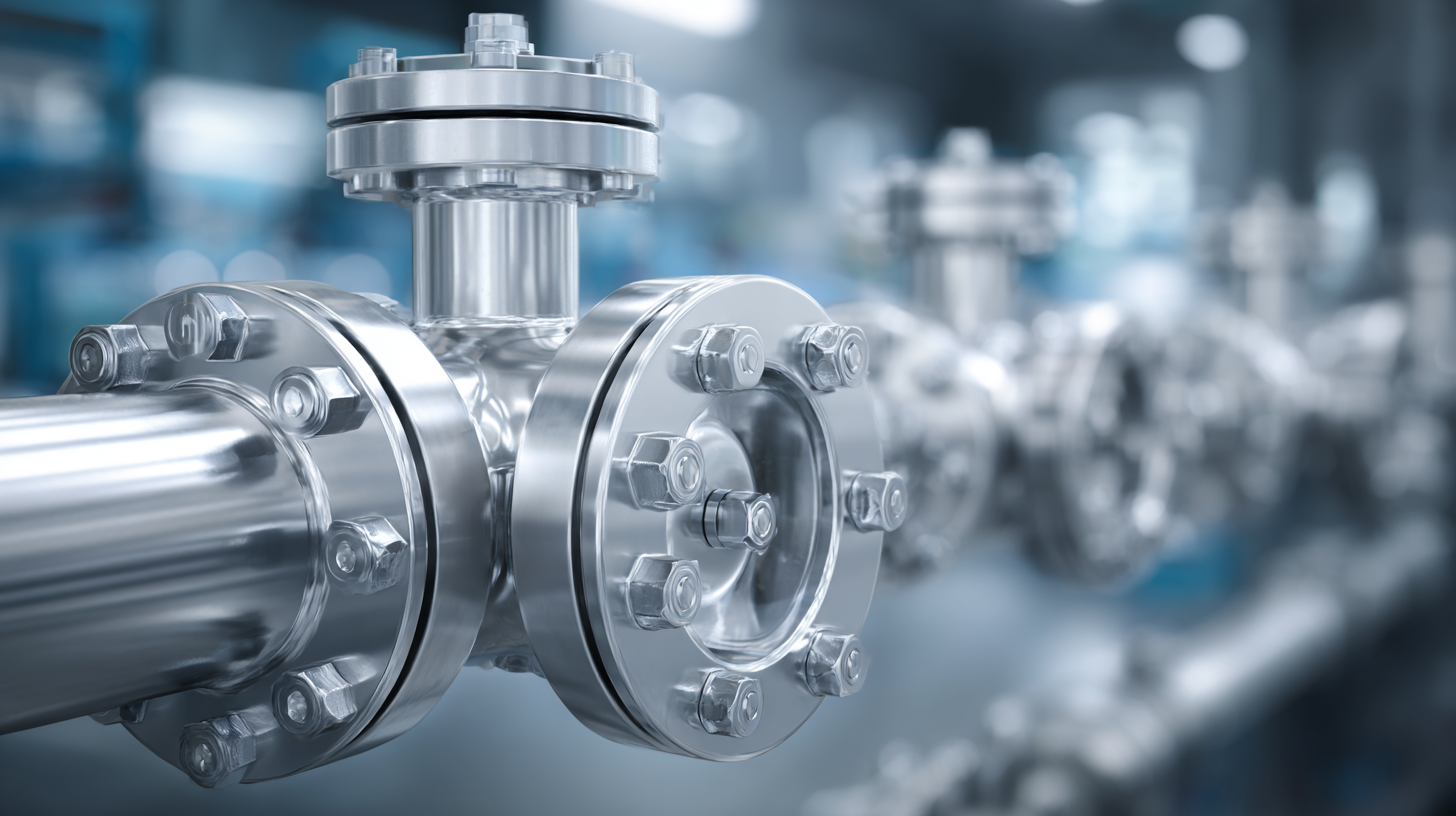

Straight valves play a crucial role in enhancing the performance of industrial systems, primarily focusing on efficiency and reliability. According to a report by the American Society of Mechanical Engineers (ASME), straight valves can reduce flow resistance by up to 30% compared to other valve types, leading to significant energy savings in fluid transport scenarios. The enhanced flow characteristics not only lower pumping costs but also minimize energy losses, making them an attractive option for industries looking to optimize their operations.

Furthermore, the reliability of straight valves is supported by data from the Valve Manufacturers Association (VMA), which indicates that properly maintained straight valves exhibit a failure rate of less than 2% over a typical lifespan. This reliability is critical in sectors such as oil and gas, where process uptime is paramount. The combination of high efficiency and exceptional reliability positions straight valves as essential components in modern industrial applications, enabling companies to meet stringent operational standards while reducing overall costs.

Understanding the Role of Straight Valves in Modern Industrial Applications

| Application |

Material |

Efficiency (%) |

Reliability (Mean Time Between Failures - MTBF in hours) |

Operating Pressure (bar) |

| Chemical Processing |

Stainless Steel |

95 |

5000 |

10 |

| Oil and Gas |

Carbon Steel |

90 |

3000 |

25 |

| Water Treatment |

PVC |

85 |

2000 |

6 |

| Food Processing |

Hygienic Stainless Steel |

92 |

4000 |

5 |

| Pharmaceutical |

316L Stainless Steel |

98 |

6000 |

7 |

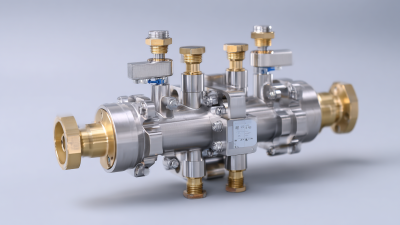

Comparative Analysis: Straight Valves Versus Other Valve Types

In the landscape of modern industrial applications, straight valves play a crucial role when compared to other valve types. According to recent market analysis, the global industrial valve market is projected to grow from $95.58 billion in revenue in 2024 to an expected $121.67 billion, underscoring the growing importance of valves in various sectors. Straight valves, known for their straightforward design and efficiency, are particularly favored in applications requiring minimal pressure drop and streamlined fluid flow.

When analyzing fluid dynamics, particularly in sophisticated systems like those outlined in various studies on cardiac dynamics, the principles apply similarly in industrial contexts. The efficiency of fluid movement in straight valves allows for optimal performance, analogous to how streamlined geometry benefits right ventricle functions in the human heart. Comparatively, while other valve types may offer specific advantages in more complex flow scenarios, straight valves consistently provide reliability and effectiveness in high-demand environments, making them a staple in today’s industrial toolkit.

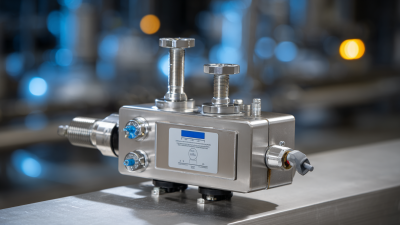

Trends in Straight Valve Technology and Future Developments

The landscape of straight valve technology is evolving rapidly, driven by advancements that enhance efficiency, reliability, and sustainability in industrial applications. According to a recent report by MarketsandMarkets, the global valve market is expected to reach $96.67 billion by 2025, growing at a CAGR of 5.9%. This growth is heavily influenced by the rising demand for automation in process industries, where straight valves play a critical role in fluid control and management.

One of the notable trends in straight valve technology is the integration of smart features, including IoT capabilities that allow for real-time monitoring and data collection. This shift is quantified in the 2022 Global Industrial Automation report, which states that 55% of manufacturers are increasingly adopting smart valve technology to improve operational efficiency and predictive maintenance strategies. Furthermore, the emphasis on eco-friendly operations is pushing for the development of materials and designs that promote reduced energy consumption and longer product lifespans, aligning with sustainability goals and regulatory demands. As industries continue to prioritize these advancements, the future of straight valves appears poised for significant innovation and relevance.