Understanding the Role of Tech Valves in Modern Industrial Automation

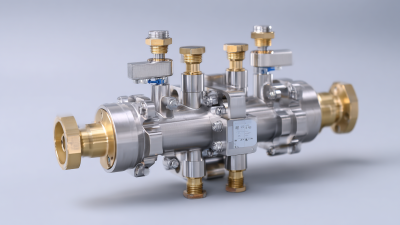

In the rapidly evolving landscape of industrial automation, the integration of advanced technologies is paramount for achieving operational excellence. One of the critical components driving this transformation is the tech valve, a sophisticated device that enhances process control and efficiency across various sectors. Tech valves not only facilitate precise flow regulation but also incorporate smart features that align with Industry 4.0 principles, enabling seamless data exchange and predictive maintenance. As industries increasingly rely on automation to optimize production, understanding the role of tech valves becomes essential. This article will explore the various functionalities of tech valves, their applications in modern industrial settings, and their impact on enhancing automation processes. By delving into these aspects, we aim to highlight how tech valves serve as indispensable tools in achieving a more efficient and intelligent manufacturing environment.

The Evolution of Tech Valves in Industrial Automation: Key Historical Milestones

The evolution of tech valves in industrial automation has been marked by several key historical milestones that have significantly influenced the efficiency and functionality of modern processes. Initially, valves were simple mechanical devices used primarily for regulating fluid flow in various systems. However, with the advancement of materials and manufacturing techniques during the Industrial Revolution, the design and functionality of valves began to evolve, paving the way for more complex applications in automation.

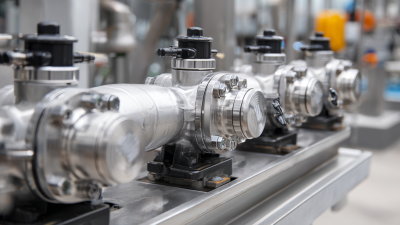

In the late 20th century, the introduction of electronic control systems revolutionized tech valves. The integration of sensors and actuators allowed for precise control over fluid dynamics, enabling industries such as petrochemicals, pharmaceuticals, and food processing to enhance their operational efficiency. The development of smart valves, equipped with real-time data monitoring capabilities, further transformed industrial automation. These innovations not only improved process reliability but also minimized downtime and maintenance costs, demonstrating the pivotal role that tech valves play in the modernization of industrial operations.

Understanding the Role of Tech Valves in Modern Industrial Automation

| Historical Milestone |

Description |

Year |

Impact on Industrial Automation |

| Introduction of Pneumatic Valves |

Development of valves operated by compressed air. |

1950s |

Increased efficiency in material handling. |

| Electromechanical Actuators |

Evolving technology for precise control in automation processes. |

1970s |

Enhanced accuracy and reduced human intervention. |

| Introduction of Smart Valves |

Integration of sensors and analytics into valve systems. |

1990s |

Real-time monitoring and predictive maintenance. |

| Wireless Valve Control Systems |

Advent of wireless communication technologies in automation. |

2000s |

Increased flexibility and reduced installation costs. |

| Artificial Intelligence Integration |

Use of AI for predictive analytics in valve operation. |

2020s |

Transforming operational efficiencies and decision-making. |

Comparative Analysis of Smart Tech Valves vs. Traditional Valves in Industrial Settings

In the current landscape of industrial automation, the comparative analysis between

smart tech valves and traditional valves reveals

significant benefits that technology brings to the manufacturing processes.

Smart tech valves, equipped with IoT capabilities,

enhance operational efficiency by providing real-time data and predictive maintenance alerts.

According to a report by MarketsandMarkets, the global smart valve market is projected to grow at a

CAGR of 15.3% from 2021 to 2026, indicating a robust shift towards automation in industries like

oil and gas, water treatment, and pharmaceuticals.

Traditional valves, while reliable, often lack the advanced features that

smart valves offer. For instance, a survey conducted

by the Industrial Internet Consortium found that companies utilizing smart valves reported a

20% reduction in downtime and a 25% increase in energy efficiency.

This is largely attributed to the valves' ability to communicate with other automation systems

and optimize performance instantly. In contrast, traditional valve systems often require manual

intervention, leading to longer response times and potential operational inefficiencies.

Impact of IoT on Tech Valve Performance and Data Management in Automation

The integration of the Internet of Things (IoT) into industrial automation has significantly transformed the functionality and management of tech valves. IoT-enabled sensors and devices facilitate real-time monitoring and control of valve operations, allowing for enhanced precision and reliability. This connectivity enables seamless communication between different components of an automated system, ensuring that tech valves can respond dynamically to changing conditions. Consequently, the performance of these valves is optimized, leading to efficient resource management and reduced operational costs.

The integration of the Internet of Things (IoT) into industrial automation has significantly transformed the functionality and management of tech valves. IoT-enabled sensors and devices facilitate real-time monitoring and control of valve operations, allowing for enhanced precision and reliability. This connectivity enables seamless communication between different components of an automated system, ensuring that tech valves can respond dynamically to changing conditions. Consequently, the performance of these valves is optimized, leading to efficient resource management and reduced operational costs.

Moreover, IoT impacts data management by generating vast amounts of operational data that can be analyzed for better decision-making. Advanced data analytics tools can harness this information to predict potential failures, optimize maintenance schedules, and improve overall system performance. By leveraging this actionable data, industries can enhance their operational strategies, ensuring that tech valves are not only functional but also integral to a well-coordinated automation ecosystem. This shift towards data-driven management demonstrates the critical role tech valves play in adapting to the demands of modern industrial environments, driven by IoT advancements.

Emerging Trends: Integration of AI and Machine Learning in Tech Valve Operations

The integration of artificial intelligence (AI) and machine learning in the operation of tech valves is transforming the landscape of modern industrial automation. By employing advanced algorithms and data analytics, industries can enhance the precision and efficiency of valve operations.

AI enables predictive maintenance, allowing for timely interventions before any failure occurs. This proactive approach not only reduces downtime but also minimizes the costs associated with unexpected malfunctions.

Moreover, machine learning algorithms can analyze vast amounts of operational data to optimize valve performance continuously. They learn from historical data to identify patterns and make real-time adjustments to improve process efficiency. This adaptive capability leads to smarter automation systems that can respond dynamically to changing operational conditions.

As a result, businesses can achieve greater control over their processes, enhancing overall productivity and safety within industrial environments. The synergy between tech valves and AI/ML is undoubtedly setting the stage for a more streamlined and intelligent industrial future.

Case Studies: Successful Implementation of Tech Valves in Various Industries

In modern industrial automation, tech valves have proven to be vital components across various sectors. One notable case study comes from the oil and gas industry, where a leading company implemented smart tech valves to enhance process efficiency. By integrating these valves with predictive maintenance sensors, the company significantly reduced downtime, resulting in a 20% increase in productivity. The real-time data collected allowed for immediate responses to system anomalies, thereby improving safety and operational reliability.

Another compelling example is found in the food processing industry, where tech valves were adopted to streamline fluid handling systems. A prominent manufacturer upgraded their outdated valves to modern actuated ones that automated the flow control during production cycles. This transition not only ensured compliance with stringent hygiene standards but also improved the accuracy of ingredient dosing. As a result, the company reported a 15% reduction in waste and enhanced product quality, showcasing the transformative impact of tech valves in industrial applications.

The integration of the Internet of Things (IoT) into industrial automation has significantly transformed the functionality and management of tech valves. IoT-enabled sensors and devices facilitate real-time monitoring and control of valve operations, allowing for enhanced precision and reliability. This connectivity enables seamless communication between different components of an automated system, ensuring that tech valves can respond dynamically to changing conditions. Consequently, the performance of these valves is optimized, leading to

The integration of the Internet of Things (IoT) into industrial automation has significantly transformed the functionality and management of tech valves. IoT-enabled sensors and devices facilitate real-time monitoring and control of valve operations, allowing for enhanced precision and reliability. This connectivity enables seamless communication between different components of an automated system, ensuring that tech valves can respond dynamically to changing conditions. Consequently, the performance of these valves is optimized, leading to