What Are Straight Valves and How Do They Optimize Fluid Control?

In the realm of fluid control systems,

"straight valves" play a pivotal role in optimizing efficiency and performance.

These specialized valves are designed to manage the flow of liquids and gases with precision,

significantly reducing pressure drops and ensuring a smoother operation within various industrial applications.

Understanding how straight valves work, along with their design features and benefits,

is essential for engineers and operators tasked with maintaining system integrity and fluid dynamics.

This article delves into the mechanics of straight valves,

exploring their operational principles, types, and the advantages they bring

to fluid control. By optimizing the pathway for fluids,

straight valves not only enhance system reliability but also contribute to overall energy conservation,

making them an indispensable component in modern fluid management strategies.

Understanding Straight Valves and Their Functionality in Fluid Systems

Straight valves are essential components in fluid systems, designed to regulate the flow of liquids or gases efficiently. Unlike other valve types, straight valves provide a direct path for fluid movement, minimizing pressure drops and turbulence. This streamlined design ensures that the fluid experiences fewer disruptions during its passage, which is crucial for maintaining system integrity and enhancing overall performance.

In operational contexts, straight valves are often utilized in applications where precise flow control is necessary, such as in pipelines, HVAC systems, and process industries. Their straightforward mechanism allows for easy adjustments and reliable sealing, making them a popular choice among engineers and technicians. Furthermore, their simplistic design not only facilitates easier maintenance but also significantly reduces the risk of mechanical failure, contributing to more robust fluid management systems.

Benefits of Using Straight Valves for Enhanced Fluid Control

Straight valves are integral components in various fluid control systems, and they offer numerous advantages that can significantly enhance operational efficiency. One of the primary benefits of straight valves is their ability to provide a direct flow path, which minimizes turbulence and pressure drops within the system. This streamlined design not only optimizes fluid flow but also reduces energy consumption, making it an environmentally friendly choice for industries relying on fluid management.

In addition to improving fluid dynamics, straight valves are typically easier to maintain and operate. Their simple construction allows for quick inspections and replacements, which can lead to less downtime and lower maintenance costs over the valve's lifespan. Furthermore, straight valves can be precisely controlled, enabling operators to achieve exact flow rates and pressures. This accuracy is vital for processes that depend on stringent specifications, such as in chemical processing, water treatment, and HVAC systems. By leveraging the benefits of straight valves, industries can ensure a reliable and efficient fluid control system, critical for maintaining productivity and safety standards.

Key Design Features of Straight Valves That Impact Performance

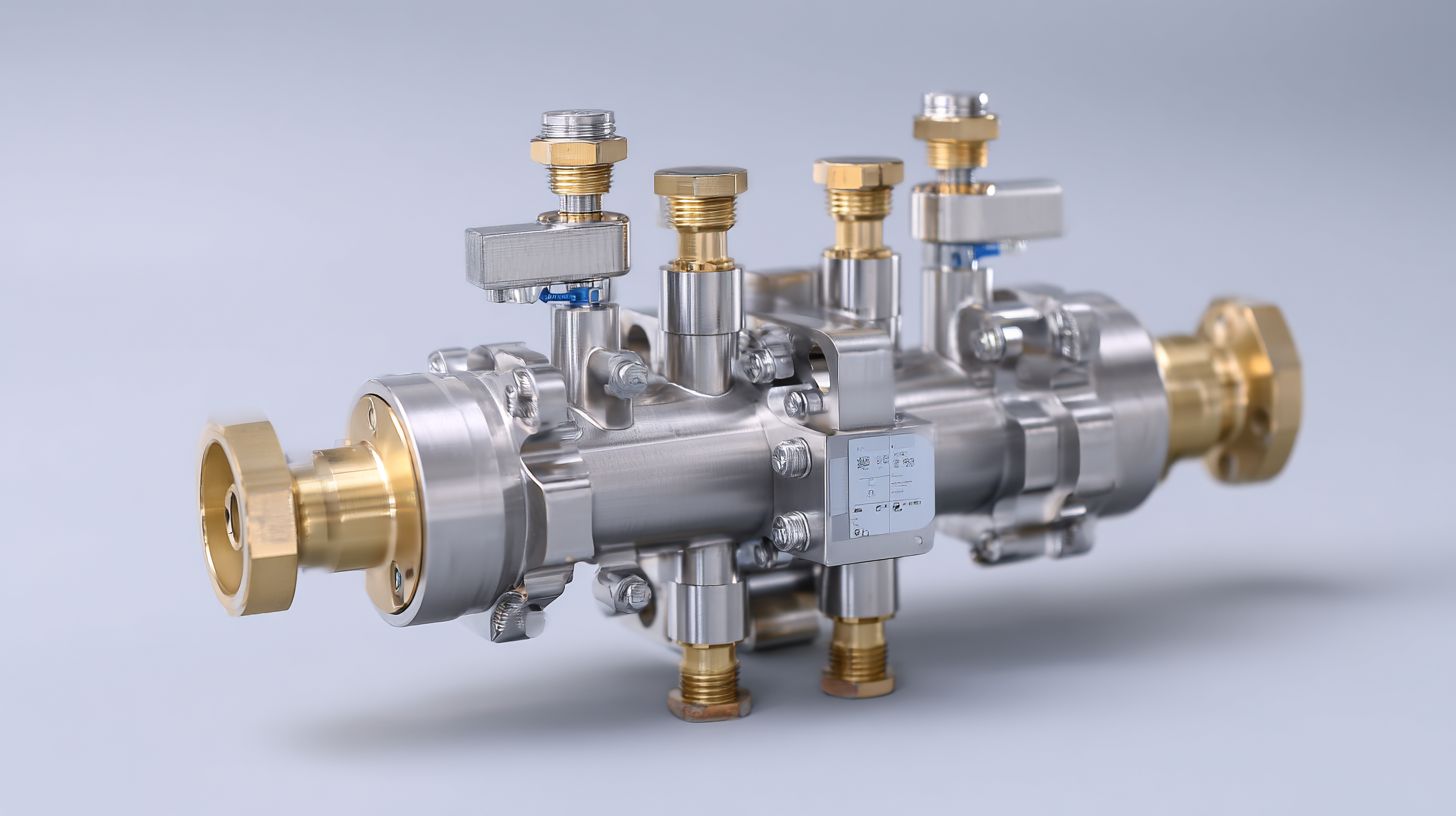

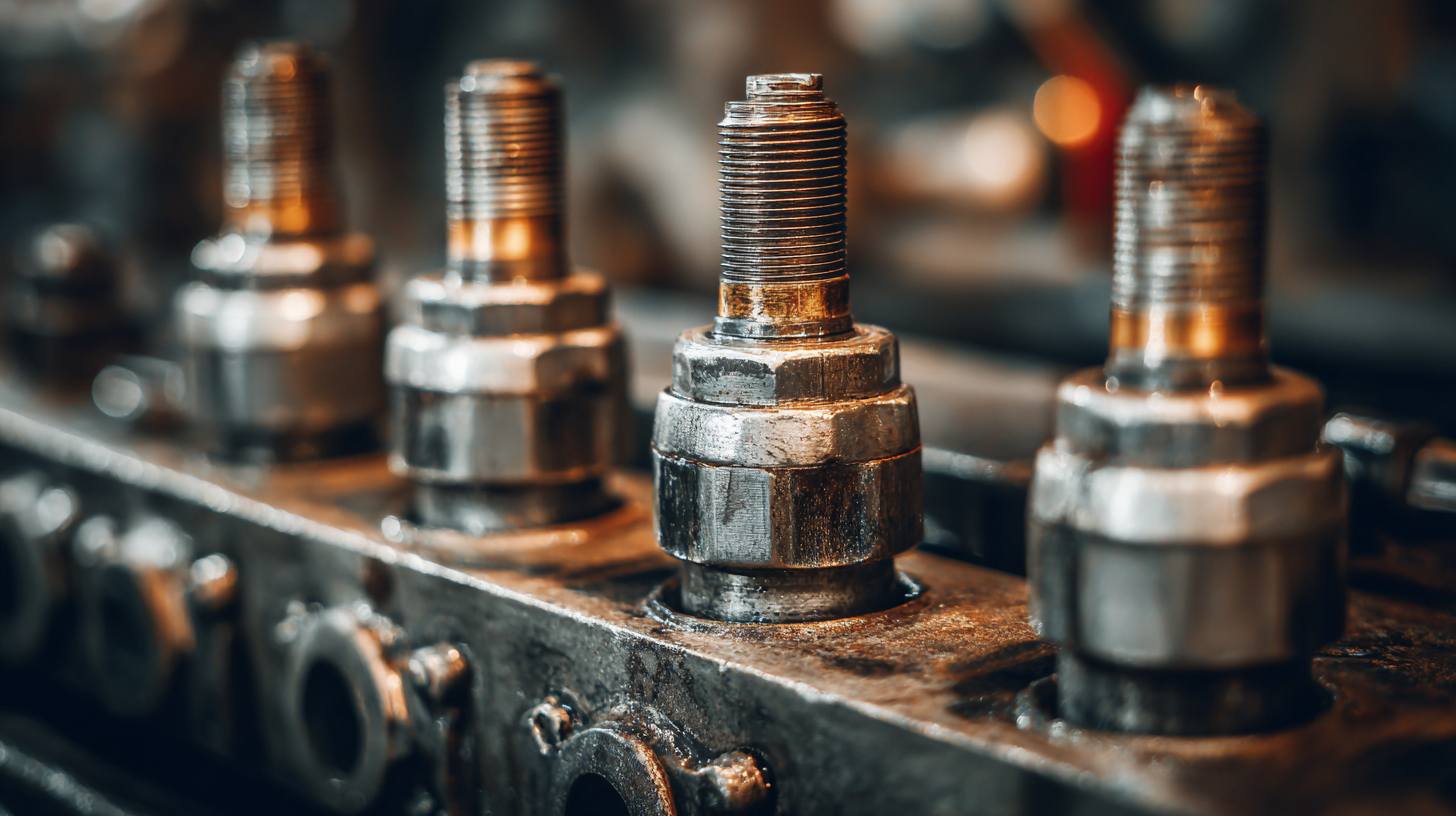

Straight valves play a crucial role in optimizing fluid control within various systems, and their design features significantly impact overall performance. One of the key characteristics of straight valves is their streamlined flow path, which minimizes turbulence and pressure drop. This efficient flow design enhances fluid velocity and ensures consistent control over the medium being transported. Additionally, the materials used in fabrication—often corrosion-resistant alloys—contribute to the longevity and reliability of the valves, making them suitable for a wide range of applications.

Another important design feature is the actuator mechanism employed in the straight valve. Electric, pneumatic, or hydraulic actuators can facilitate precise control over valve opening and closing, allowing for quick adjustments in fluid flow as needed. The ability to implement automation further improves efficiency and accuracy, particularly in complex systems where real-time monitoring and response are essential. Furthermore, the compact design of straight valves allows for easier integration into existing piping systems without requiring extensive modifications, enabling smoother operations and maintenance. These design elements collectively enhance the performance of straight valves, making them indispensable in fluid management.

Common Applications of Straight Valves in Various Industries

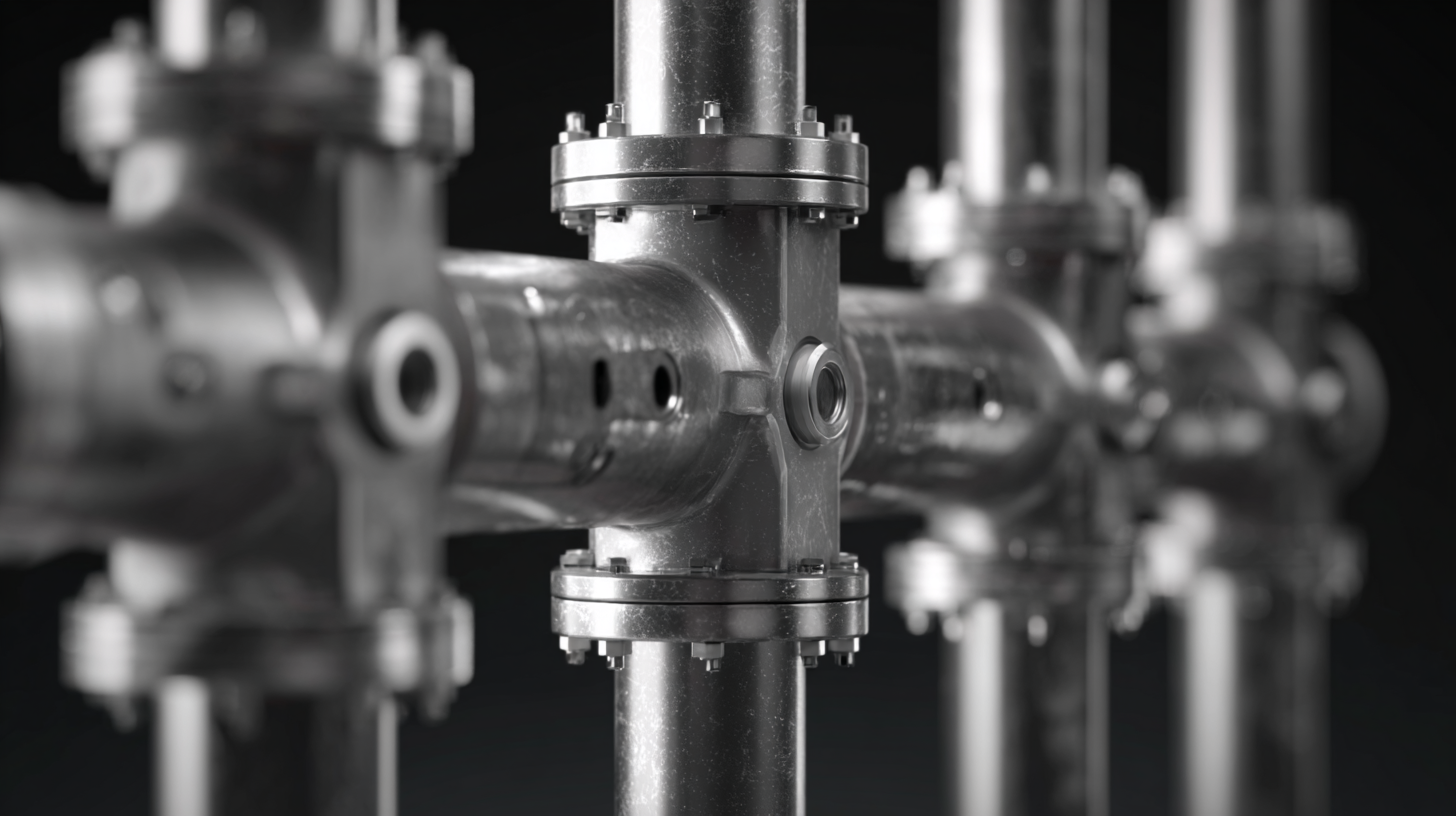

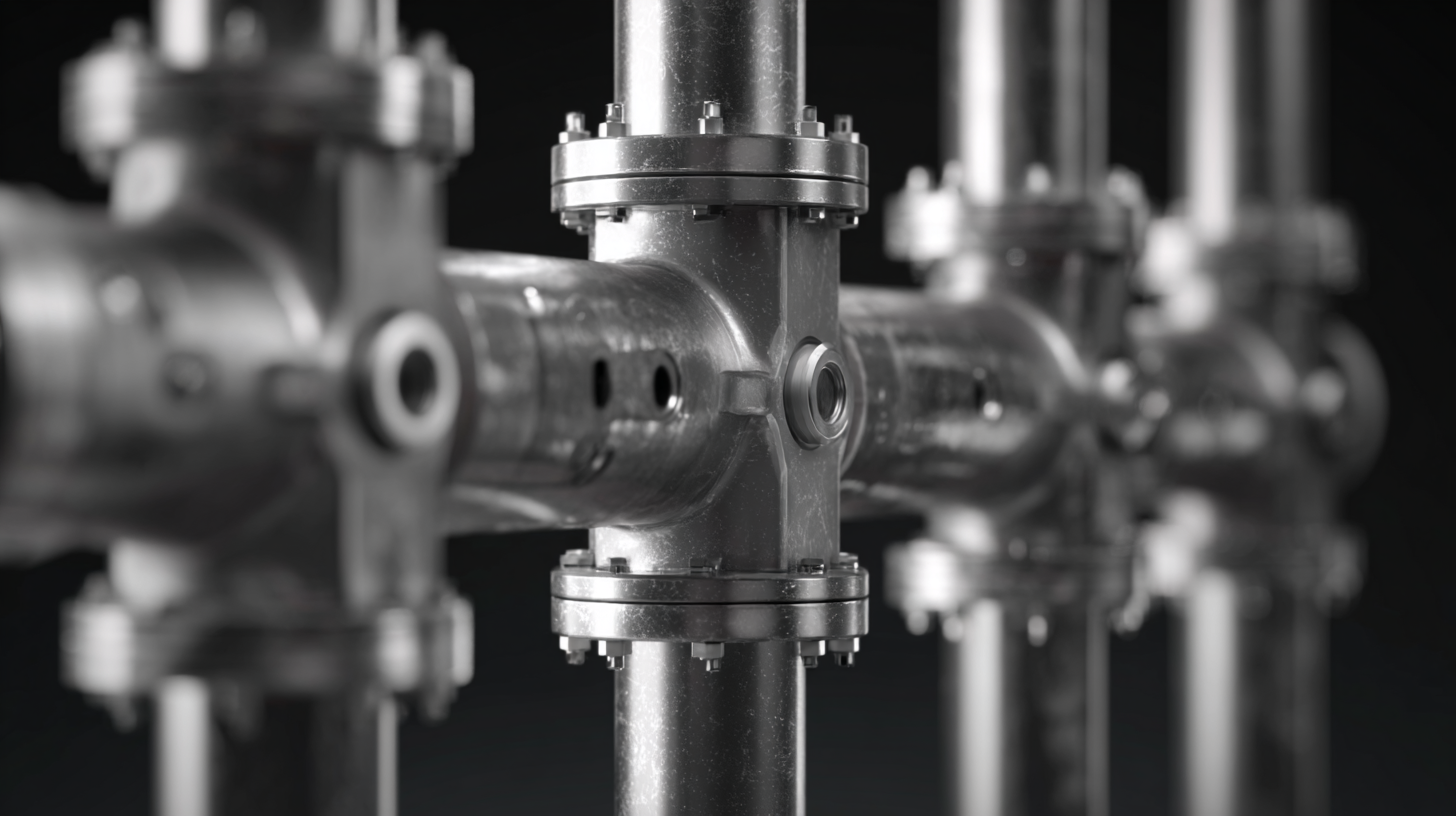

Straight valves play a crucial role in various industries due to their efficient design and functionality. Commonly found in sectors such as water treatment plants, chemical processing, and oil and gas, these valves facilitate optimal fluid control by allowing straight, unimpeded flow paths. This design minimizes pressure drops and turbulence, ensuring that fluids can be regulated with maximum efficiency. For instance, in water treatment facilities, straight valves are often utilized to manage the flow of water through filtration systems, contributing to both improved performance and reduced energy costs.

In addition to water management, straight valves are prevalent in the chemical industry, where they control the flow of reactants and products in chemical reactors. Their straightforward construction allows for easy maintenance and replacement, which is essential in high-demand production environments. Moreover, in the oil and gas sector, straight valves are vital for controlling the flow of hydrocarbons and ensuring safe operation in pipelines. Their ability to handle high pressures and temperatures while providing precise flow regulation makes them indispensable in these applications, enhancing both safety and operational reliability.

Expert Tips for Choosing the Right Straight Valve for Your Needs

When it comes to optimizing fluid control in various applications, choosing the right straight valve is crucial. Straight valves provide a direct flow path, minimizing turbulence and pressure drops, which enhances efficiency in systems such as cooling, heating, and even in industrial processes. Understanding the specific requirements of your system, such as pressure ratings, flow rates, and compatibility with fluid types, is essential in making a well-informed selection.

Experts recommend considering factors like material construction and valve size to ensure durability and performance. Different industries may have unique standards or specifications, so consulting with a knowledgeable supplier can provide insights into the best options available. Additionally, evaluating the ease of installation and maintenance of the valve can further streamline operations in the long run. By taking these expert tips into account, you can confidently select a straight valve that meets your specific fluid control needs effectively.

Fluid Control Optimization with Straight Valves