Top 10 Water Valve Types You Should Know About?

In the world of plumbing and fluid management, understanding various water valve types is crucial. "Choosing the right water valve can significantly impact efficiency and safety," says Dr. Emily Chen, a leading expert in hydraulic systems. This statement highlights the importance of knowing not just the functions of water valves, but also their applications.

Water valves play a vital role in controlling water flow. There are numerous types available, each serving specific purposes. Some valves are designed for high-pressure systems, while others cater to low-flow environments. Without proper knowledge, one might select an inappropriate valve, leading to inefficiencies or even hazards.

Moreover, not all valves are created equal. Each type has unique features. Familiarity with them can aid in making informed decisions. However, it’s easy to overlook these details. Understanding their functions requires attention and experience. As the industry evolves, so do the technologies behind water valves, making continuous learning essential for professionals.

Understanding the Basics of Water Valves

Water valves play a crucial role in managing water flow. They control the distribution of water in plumbing systems, irrigation, and industrial processes. Understanding the basics of water valves helps you make informed choices. Each type has unique features and benefits, suited for specific needs.

There are various types of water valves. Gate valves are great for on-off control, while globe valves offer fine-tuning. Ball valves provide quick shut-off, making them popular. Butterfly valves are efficient for larger flows, but installation can be tricky. The choice of valve often depends on pressure and flow requirements. Some valves may leak if not installed properly.

Maintenance is vital for optimal performance. Clogged valves can cause significant issues. Regular inspections help identify problems early. Over time, wear and tear can lead to failures. A comprehensive understanding of these valves aids in preventing costly repairs or downtime. Choosing the right type and ensuring proper installation are critical steps.

Different Types of Water Valves and Their Functions

Water valves are essential components in plumbing systems. They regulate water flow and pressure efficiently. Knowing different valve types can help in making informed choices. Common types include ball valves, gate valves, and check valves, each serving specific functions.

Ball valves are popular due to their simple design. They have a spherical disc that allows or blocks flow. This type is quick to open and close. Gate valves, on the other hand, are used for on/off control but may not be ideal for throttling. They provide minimal resistance. Check valves prevent backflow. These valves ensure that water flows in one direction only, improving safety.

It's important to choose the right valve type based on your needs. Some may leak over time, causing frustration. Installation can be tricky for beginners, and errors can lead to leaks. Understanding the purpose of each valve is crucial. It can save you from costly repairs. Always consider maintenance needs when selecting a valve.

Applications of Common Water Valve Types

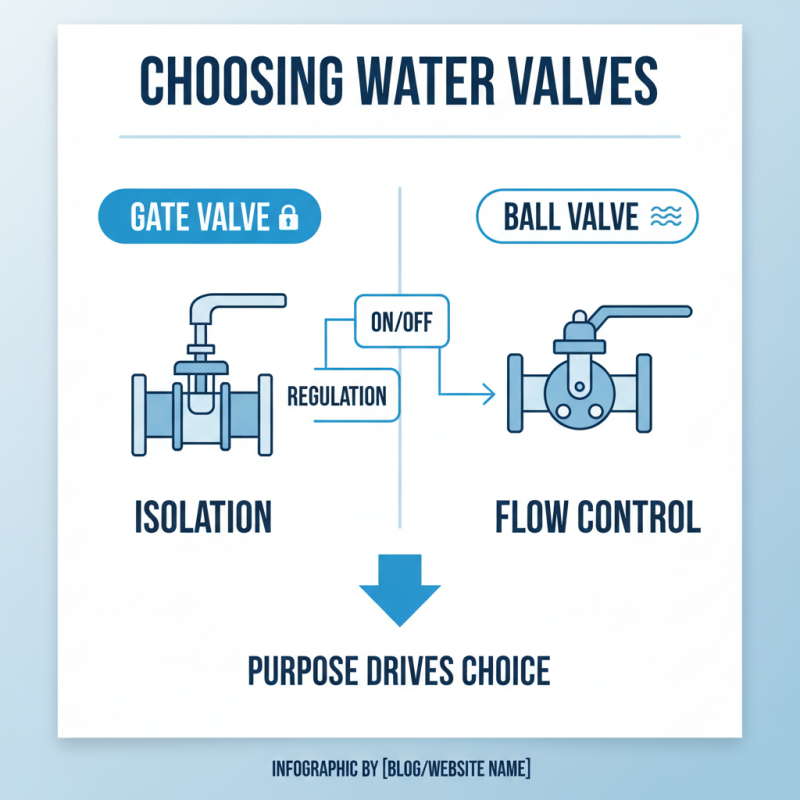

Water valves play a critical role in managing the flow of water in various applications. Different types of water valves serve unique purposes in residential and industrial settings. For instance, gate valves are often used in water supply systems, providing a straightforward on/off control. These valves are durable and can be used in high-pressure situations, but their slow operation might not suit all scenarios.

Ball valves are another common type. They allow for quick flow control and minimal pressure drop. This makes them ideal for systems requiring rapid adjustments, like irrigation. However, if not maintained properly, they can wear down over time. Additionally, check valves prevent backflow, protecting systems from potential damage. The application of a globe valve is typically found in throttling flow or as a stop valve. While they excel in flow regulation, they can become inefficient in larger systems.

Different applications require careful consideration of the type of water valve used. Choosing the right valve type is not always straightforward. Users should reflect on the specific needs of their systems. Each valve type has its pros and cons. Understanding these can lead to better water management decisions.

Key Features to Consider When Choosing a Water Valve

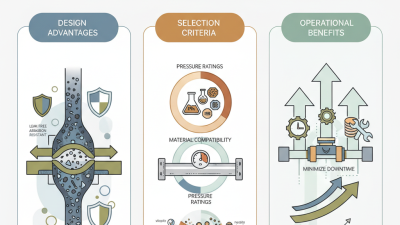

When choosing a water valve, several key features come into play. Start with the valve's type. Gate valves, for instance, are perfect for isolation, while ball valves offer better flow control. Each type serves a distinct purpose. Understanding these differences will help in making an informed choice.

Consider the valve's material. Common options include brass, stainless steel, and PVC. Each material affects durability and cost. Brass is resilient but can corrode. PVC is lightweight but may not withstand high temperatures. Evaluate the specific needs of your project before making a decision.

Don't overlook the valve's size. Proper sizing ensures efficiency and functionality. Using a valve that is too large or small can lead to leaks or pressure issues. Additionally, think about the valve's pressure rating and temperature tolerance. These factors can significantly impact the valve's performance over time.

Maintenance Tips for Ensuring Valve Longevity

Water valves are crucial in many systems, and proper maintenance is vital for their longevity. Regular inspections can prevent costly breakdowns. For instance, the American Society of Mechanical Engineers states that neglecting valve maintenance can reduce lifespan by over 50%. Simple checks, like examining for leaks or corrosion, can identify issues early. This prevents extensive damage and costly repairs.

Cleaning valves routinely is also essential. Deposit buildup can restrict flow and damage components. A study from the Valve Manufacturers Association revealed that 70% of valve failures stem from inadequate maintenance. Regularly flushing the system can help keep valves working properly. Use appropriate cleaning agents to avoid harmful reactions with valve materials.

Documenting maintenance activities is important but often overlooked. Tracking repairs can provide insights into recurring issues. Such documentation helps develop better maintenance strategies. Over time, this can lead to significant cost savings. Actively engaging with valve maintenance isn’t just about quick fixes; it’s about creating a culture of care and foresight.