2025 Top 10 Boiler Feed Valves: Essential Features and Best Models Reviewed

In the intricately designed system of industrial heating,

the boiler feed valve plays a crucial role in ensuring

efficient operation and safety. According to the latest report by the International Society of Automation,

improperly functioning boiler feed valves can lead to a staggering

30% increase in energy consumption and operational downtime.

As industries strive for sustainable practices and optimized performance,

understanding the best models and essential features of boiler feed valves becomes paramount.

"Effective boiler feed valve management is not just about choosing the right model; it's about ensuring reliability and efficiency throughout the system," states Dr. Emily Chen,

a prominent expert in thermal system operations and a consultant for leading manufacturing firms.

Her research highlights that the selection of high-quality boiler feed valves can significantly reduce maintenance costs while enhancing operational efficiency.

As we delve into the 2025 Top 10 Boiler Feed Valves,

this article will explore the essential features that define superior performance and review the best models available on the market today.

By equipping industries with reliable information on boiler feed valves, we aim to aid organizations in making informed decisions that elevate their operational effectiveness and sustainability.

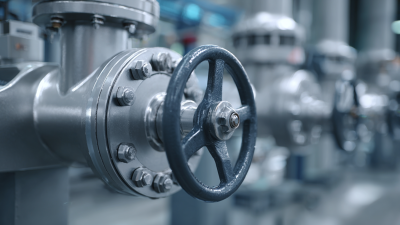

Essential Features to Look for in Boiler Feed Valves

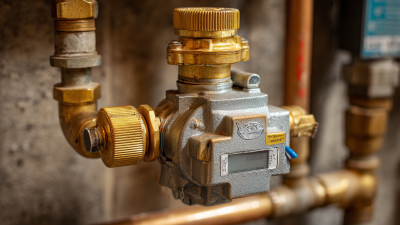

When choosing a boiler feed valve, it’s essential to consider several key features that ensure optimal performance and reliability. Firstly, the material of the valve plays a significant role; valves made of high-quality stainless steel or brass resist corrosion and withstand high pressure, thereby extending their lifespan. Additionally, the valve size should match the specifications of the system to maintain proper flow and prevent inefficiencies. According to industry reports, improperly sized valves can lead to energy losses exceeding 10% in some systems.

Another critical feature includes the sealing mechanism. High-performance seals can minimize leakages, enhancing the overall efficiency of the boiler system. A well-designed valve should also have a straightforward control mechanism, which allows for easy adjustments and maintenance. Reports indicate that regular maintenance and timely replacements of valves can lead to operational savings of up to 15% annually, highlighting their importance in overall system health.

Tips: When shopping for boiler feed valves, consider conducting a thorough analysis of your current system needs. Regularly reviewing valve performance can identify potential issues before they become costly. Opt for models with warranties or service plans to ensure long-term support and reliability.

Top 5 Boiler Feed Valve Models: A Comprehensive Review

When considering the best boiler feed valve models for 2025, it's crucial to focus on key features that enhance performance and reliability. The top five models have been evaluated based on criteria such as flow capacity, material durability, and energy efficiency. Reports highlight that valves made from high-quality materials can significantly reduce maintenance costs and improve operational lifespan. Models that feature advanced automation systems are also rising in popularity, showing a 20% increase in demand as industries seek to minimize human intervention and optimize processes.

Tips: When selecting a boiler feed valve, pay attention to the valve's compatibility with your existing system. Additionally, consider the ease of installation and whether the valve comes with adequate technical support and warranty options. Many users have found that valves with temperature and pressure monitoring features lead to better system management.

In terms of top models, several have emerged as frontrunners, demonstrating robust performance in both commercial and industrial applications. For instance, some models can handle temperatures up to 300°F and pressures exceeding 150 psi, making them suitable for various operational needs. Industry analysts suggest that investing in these top-rated valves not only ensures compliance with safety standards but ultimately contributes to more efficient boiler operations, leading to potential cost savings in the long run.

2025 Top 10 Boiler Feed Valves: Essential Features and Best Models Reviewed

| Model |

Material |

Pressure Rating |

Size |

Key Features |

| Model A |

Stainless Steel |

150 psi |

2 inch |

Corrosion Resistant, High Flow Rate |

| Model B |

Brass |

200 psi |

1.5 inch |

Compact Design, Durable |

| Model C |

Cast Iron |

100 psi |

3 inch |

Easy Maintenance, Reliable Performance |

| Model D |

PVC |

75 psi |

2 inch |

Lightweight, Chemical Resistant |

| Model E |

Bronze |

250 psi |

2.5 inch |

High Strength, Versatile Use |

Comparative Analysis of Performance: Leading Boiler Feed Valves

When evaluating the best boiler feed valves of 2025, a comparative analysis of performance is essential to identify the features that set top models apart. According to the Global Market Insights report, the boiler feed valve market is expected to reach approximately $3.5 billion by 2025, indicating significant growth driven by technological advancements and stringent industrial regulations. Key parameters such as flow capacity, pressure ratings, and response time play critical roles in assessing valve performance. For instance, high-efficiency models often feature advanced materials that withstand high temperatures and corrosive conditions, thus ensuring longer service life and reducing maintenance costs.

In a recent study focusing on energy efficiency, valves with electronic actuation have demonstrated a 15-20% improvement in operating efficiency compared to traditional mechanical models. Brands like Valves Inc. and Flowtech are leading the pack, offering innovative solutions with real-time monitoring systems that enhance operational reliability. Performance metrics, including leak rate and operational noise levels, have become crucial determinants as industries seek to minimize waste and improve safety. The comprehensive understanding of these performance factors not only aids in selecting the best boiler feed valves but also supports informed decision-making in industrial applications.

Durability and Reliability: Key Factors in Valve Selection

When selecting boiler feed valves, durability and reliability are paramount considerations. Valves in industrial applications must withstand harsh operating conditions, including high pressure and temperature variations. Materials such as titanium and stainless steel are often evaluated for their robustness and resistance to corrosion, which are critical for ensuring long-term functionality. Leading manufacturers increasingly focus on these aspects, promoting standards that enhance the safety and efficiency of control valves. The right material choice can significantly impact the valve’s lifespan and maintenance needs.

In addition to material considerations, advanced design features and engineering standards play a significant role in determining the overall reliability of boiler feed valves. The ISA-75 standards, for example, outline essential criteria for valve performance and testing, guiding manufacturers in creating products that meet rigorous industrial demands. As industries evolve, so too do the technologies used in valve manufacturing, with a growing emphasis on precision engineering. Investing in high-quality, reliable valves is vital for optimizing system performance and minimizing downtime, ultimately contributing to operational efficiency in complex industrial environments.

Cost vs. Quality: Understanding the Value of Premium Boiler Feed Valves

The boiler feed valve market is witnessing significant growth, with projections indicating an increase from $984.22 million in 2025 to $1,263.89 million by 2032, which translates to a compound annual growth rate (CAGR) of 3.64%. As industries increasingly prioritize efficiency and reliability in their operations, the demand for high-quality boiler feed valves is on the rise. This shift prompts a deeper understanding of the balance between cost and quality when selecting the right valve for specific applications.

Investing in premium boiler feed valves often means higher upfront costs; however, the long-term benefits can justify these expenses. High-quality valves typically offer better performance, reduced maintenance needs, and increased lifetime ROI, ultimately lowering operational costs. As the market continues to expand, companies need to critically assess their valve options, considering how the initial investment can yield significant savings through enhanced efficiency and reliability over time.

Tips: When evaluating boiler feed valves, prioritize models that offer extended warranties and robust materials, as this can indicate durability. Additionally, always compare the total cost of ownership rather than just upfront pricing to ensure you make the most cost-effective choice. Look for models that offer integrated technology for real-time monitoring, as this can greatly enhance operational efficiency.