2025 Top Boiler Valve Innovations for Optimal Performance and Efficiency

As the industrial landscape rapidly evolves, the demand for enhanced performance and efficiency in boiler systems has never been more crucial. In this context, the role of innovative boiler valve technologies stands at the forefront. These advancements not only optimize the operational reliability of boilers but also contribute significantly to energy conservation and sustainability initiatives. By addressing common inefficiencies and integrating smart technologies, the 2025 wave of boiler valve innovations promises to reshape the way we approach boiler management, ensuring that these critical components work harmoniously to achieve peak performance.

In this exploration of "2025 How to" innovations, we will delve into the latest developments in boiler valve design and functionality. From advanced materials that enhance durability and heat resistance to refined control mechanisms that allow for precision in operation, the upcoming trends will be elucidated. By understanding these key innovations, industry professionals, engineers, and decision-makers will be better equipped to make informed choices that lead to improved efficiency and reduced operational costs within their boiler systems.

Join us as we uncover the transformative potential of the next generation of boiler valves.

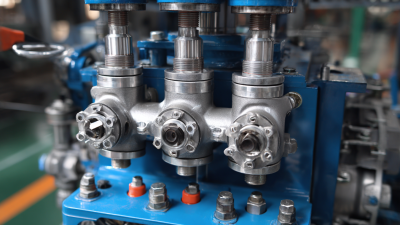

Innovative Materials in Boiler Valve Manufacturing for Enhanced Durability and Performance

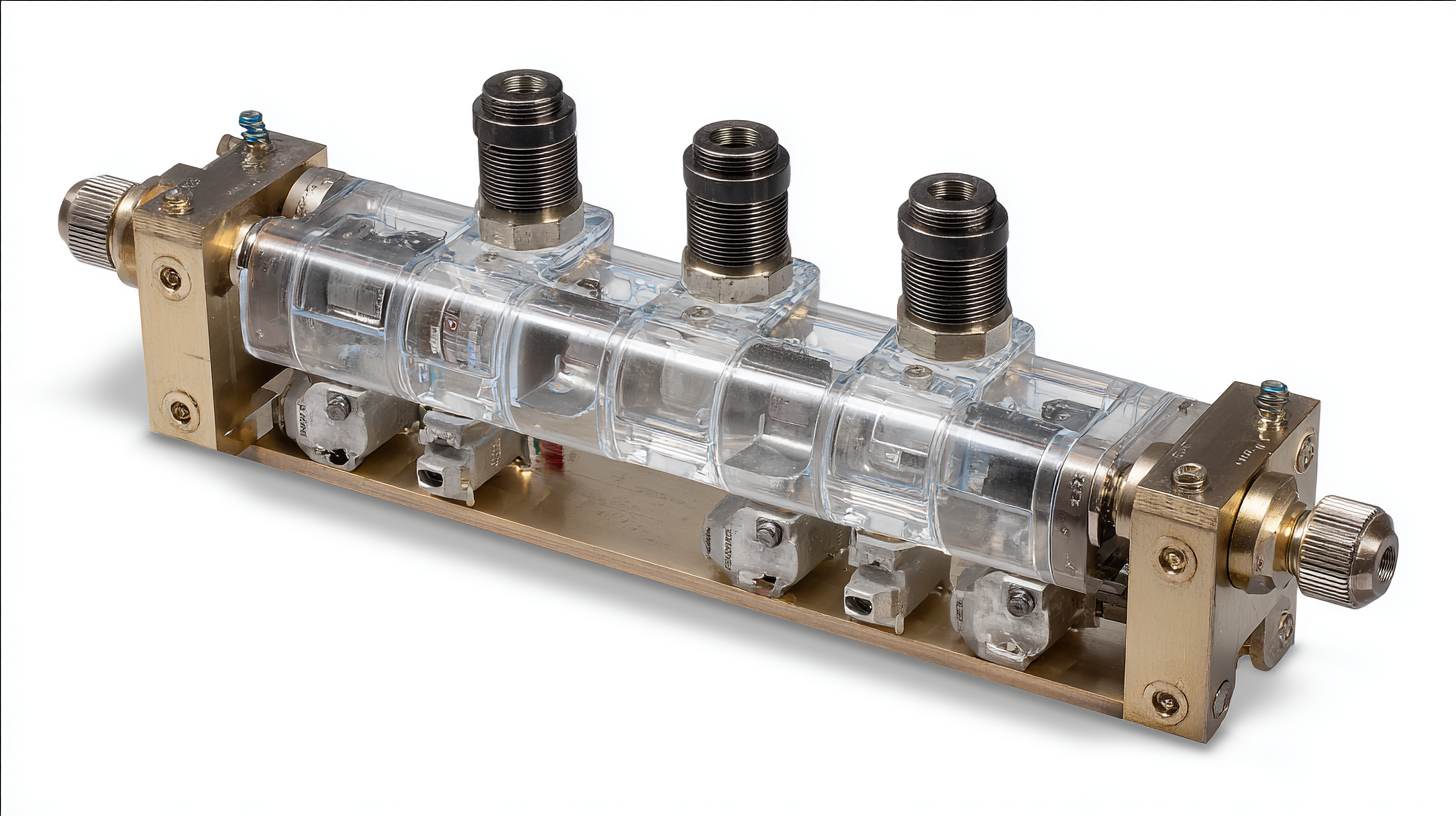

In recent years, the demand for enhanced durability and performance in boiler valve manufacturing has led to significant innovations in materials. As industries strive for optimal performance and efficiency, manufacturers are increasingly exploring advanced materials that not only withstand extreme conditions but also promote operational longevity. Innovations in ceramic composites and high-performance alloys are at the forefront, providing solutions that reduce wear and corrosion, ultimately extending the lifespan of boiler valves.

Moreover, these new material technologies enhance overall system efficiency, minimizing maintenance costs and downtime. With the increasing use of smart manufacturing techniques, it is now possible to integrate these innovative materials into designs that facilitate better flow control and pressure regulation. As we look ahead to 2025, the focus on these innovations will undoubtedly play a crucial role in shaping the future of boiler valve applications, driving the industry towards greater sustainability and performance.

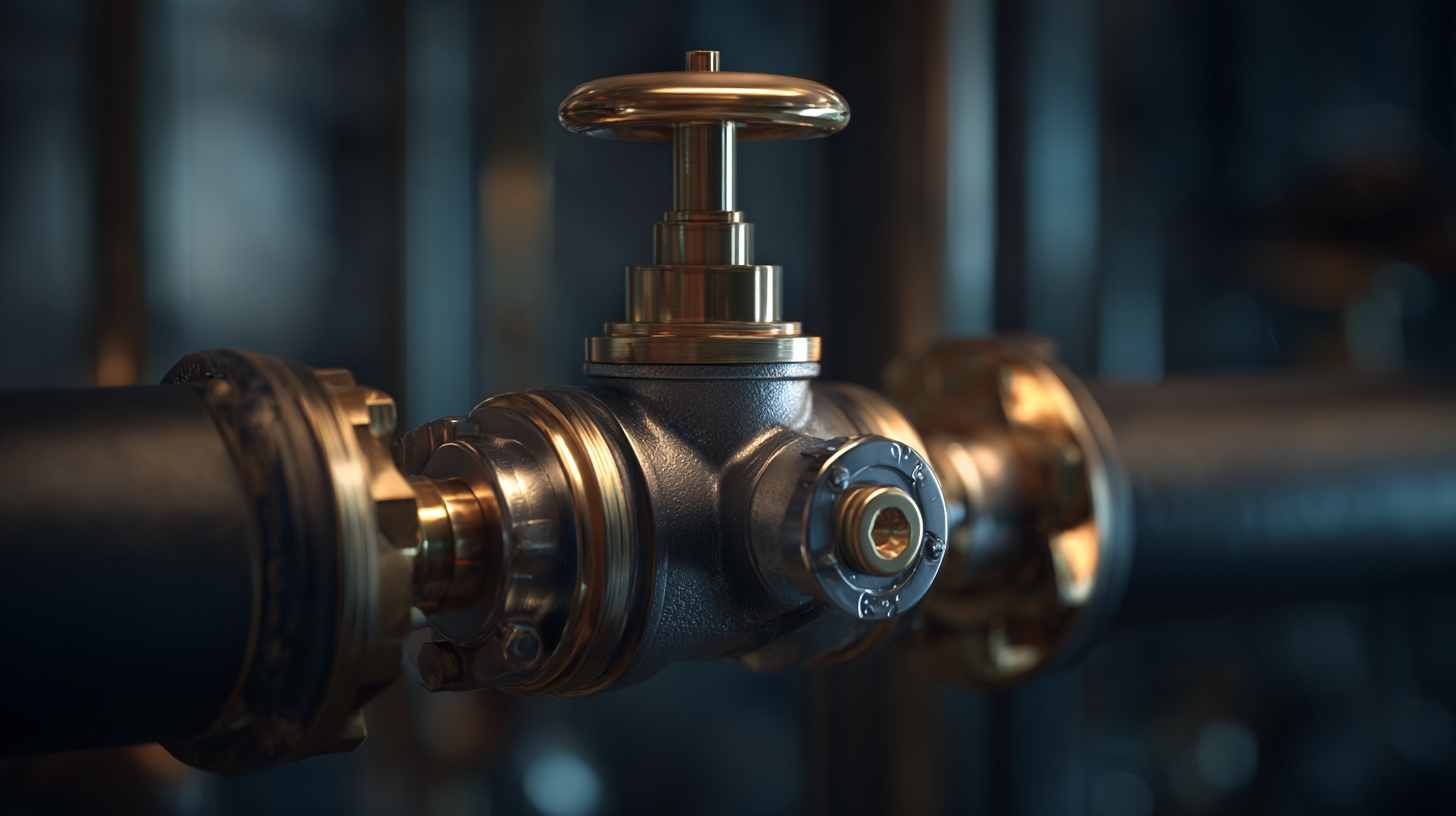

Energy Efficiency Gains: Analyzing the Latest Boiler Valve Designs and Their Impact

The demand for energy efficiency in industrial operations has never been more critical, and recent innovations in boiler valve designs are leading the charge towards optimized performance. According to a report by the U.S. Department of Energy, up to 30% of energy consumption in steam systems can be attributed to inefficiencies in valve operations. New valve technologies, such as smart electronic valves equipped with real-time monitoring capabilities, are revolutionizing the way facilities manage steam flow. These designs not only provide precise control but also significantly reduce energy losses, leading to a more sustainable operation.

Moreover, advancements in materials science are yielding lightweight yet durable valve components that improve thermal insulation and reduce overall system weight. A study from the International Energy Agency highlights that implementing high-performance boiler valves can enhance energy efficiency by an average of 12% across various applications. These innovations are paving the way for industries to meet regulatory standards while simultaneously driving down operational costs. As boiler systems evolve, the impact of these state-of-the-art valve designs on energy efficiency will be profound, making them a crucial focus for both manufacturers and end-users alike.

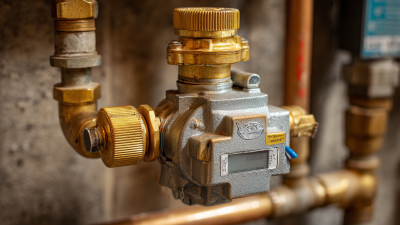

Smart Technology Integration: How IoT-Enabled Boiler Valves Improve Operational Efficiency

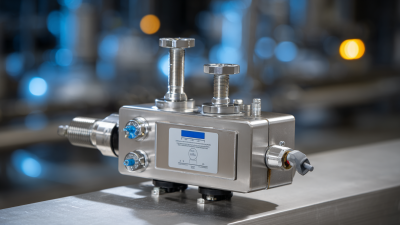

The integration of smart technology into boiler valves marks a significant advancement in operational efficiency. IoT-enabled boiler valves harness artificial intelligence to provide real-time operational intelligence, enabling proactive maintenance and optimization of performance. By analyzing data from various sensors, these valves can predict potential failures before they occur, thereby reducing downtime and maintenance costs. This level of automation not only streamlines operations but also contributes to a more sustainable approach to energy management.

Furthermore, the sustainable water treatment technologies embedded within these advanced valves help minimize environmental impact. By ensuring optimal water quality and reducing waste, boiler systems can operate more efficiently. Decentralized infrastructures enhance this efficiency by allowing for localized control and management, thus improving response times and operational adaptability. Additionally, the integration of flood prevention features into the design ensures enhanced safety and reliability in the face of changing environmental conditions. As the industry moves toward these innovations, the potential for increased efficiency and performance becomes remarkably evident.

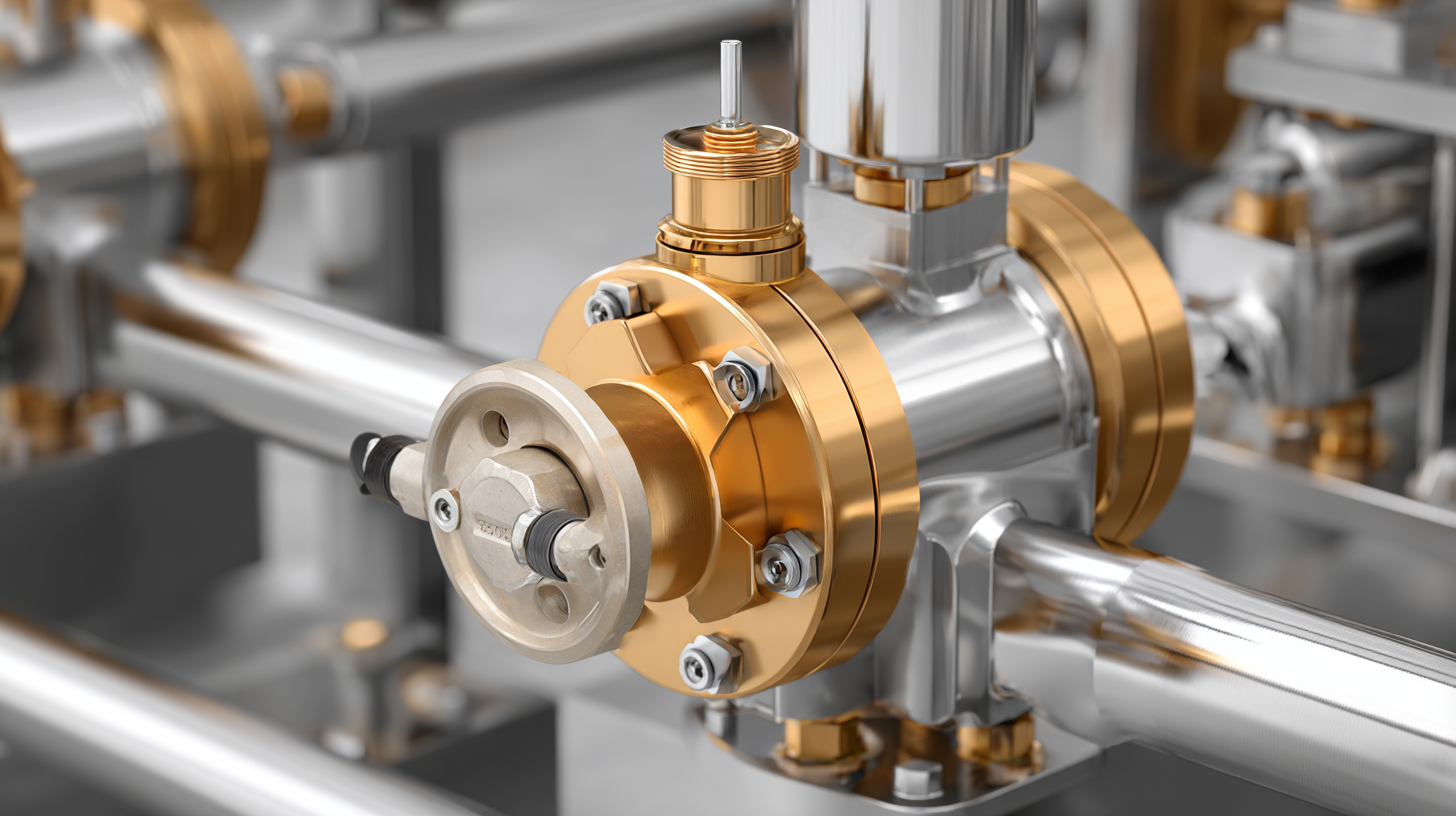

Advancements in Valve Automation: Streamlining Boiler Operations for Increased Reliability

The advancement of valve automation in boiler systems is rapidly transforming industry practices, aiming to enhance both reliability and efficiency. According to a report by the Global Valve Automation Market Analysis, the automation sector is projected to grow at a CAGR of 7.1% from 2023 to 2028, driven by the increasing demand for precision and control in boiler operations. These innovative automation solutions not only minimize human error but also optimize the performance of boilers, leading to substantial energy savings.

Recent developments in smart valve technologies have enabled real-time monitoring and predictive maintenance, significantly reducing operational downtime. For instance, a study by the International Energy Agency noted that implementing advanced automation can lead to a 15-30% increase in boiler efficiency. By integrating Internet of Things (IoT) capabilities, operators can remotely manage valve functions, ensuring that boiler systems operate within their optimal parameters under varying load conditions. This level of automation not only streamlines operations but also aligns with the industry’s push towards more sustainable and efficient energy solutions.

Sustainability in Boiler Valve Innovations: Reducing Carbon Footprint and Energy Waste

As the industrial sector advances towards more sustainable practices,

boiler valve innovations are emerging as pivotal in reducing both carbon footprints and energy waste.

State-of-the-art designs now prioritize efficiency, allowing for smarter energy utilization while maintaining optimal performance.

The integration of advanced materials and smart technology in boiler valves means they can respond to operational demands in real-time,

significantly lowering emissions and enhancing overall process sustainability.

Tips for maximizing your boiler valve efficiency include regular maintenance checks to ensure seals are intact and that there are no leaks,

which can lead to energy loss. Additionally, consider investing in valves with better insulation properties to reduce heat loss during operations.

Another proactive approach is to utilize smart monitoring systems that can alert operators of any anomalies,

ensuring that energy waste is minimized and operational efficiency is maximized.

By embracing these innovations, industries can not only meet regulatory standards but also contribute to a more sustainable future.

Opting for eco-friendly designs and smart technologies creates a path towards a greener operation,

where both performance and environmental responsibility go hand in hand.