Top 10 Electric Valve Types You Need to Know for Efficient Control

In today’s industrial landscape, the efficiency and precision of control systems are paramount, making electric valves an essential component across various sectors. According to a recent study by Market Research Future, the global electric valve market is projected to grow significantly, reaching USD 6.25 billion by 2025, driven by the increasing demand for automation and control in process industries. Understanding the different types of electric valves is crucial for optimizing operations and ensuring reliability.

Industry expert Dr. Emily Harrison, a prominent figure in fluid control systems, emphasizes the importance of choosing the right valve type:

“Selecting the appropriate electric valve can enhance operational efficiency and reduce maintenance costs, making it a key consideration for any engineering project.”

As we delve into the top 10 electric valve types, it becomes clear that each plays a unique role in improving system performance and achieving desired control outcomes. From globe valves to butterfly valves, the selection of the right valve type can have a significant impact on not just the mechanical aspects but also on the energy efficiency and sustainability of operations.

Top Electric Valve Types Revolutionizing Industry Control in 2025

As industries evolve, the shift towards electric valve technology is pivotal for enhancing control systems. With the valve remote control system market projected to surpass USD 8.6 billion by 2024 and grow at a 6.5% CAGR through to 2034, the integration of advanced electric valves is becoming more critical than ever. These valves are transforming operational efficiency, ensuring safety, and enabling precision control in various sectors, including HVAC and hydraulics.

In the HVAC controls market, anticipated growth from USD 25.81 billion in 2025 to USD 39.07 billion by 2030, at a CAGR of 8.6%, reflects a burgeoning demand for innovative control solutions. Electric valves are central to this trend, facilitating better energy management and system responsiveness. As organizations seek to optimize processes and reduce operational costs, the adoption of cutting-edge electric valve types is expected to revolutionize control mechanisms across industries by 2025, promoting not only efficiency but also sustainability.

Top 10 Electric Valve Types You Need to Know for Efficient Control - Top Electric Valve Types Revolutionizing Industry Control in 2025

| Valve Type |

Operating Principle |

Applications |

Advantages |

| Solenoid Valve |

Electromagnetic |

Automotive, HVAC |

Fast switching, Compact design |

| Butterfly Valve |

Rotary movement |

Water management |

Space-saving, Low pressure drop |

| Ball Valve |

Rotary ball |

Oil and Gas |

Durable, Tight seal |

| Gate Valve |

Linear motion |

Water supply |

Minimal pressure drop, Full flow |

| Check Valve |

Automatic flow direction |

Pipelines |

Prevents backflow, Reliable |

| Globe Valve |

Linear motion |

Fluid regulation |

Precise control, Good throttling |

| Pressure Relief Valve |

Pressure detection |

Safety systems |

Safety, Prevents overpressure |

| Dimensional Valve |

Rotary movement |

Chemical processing |

Accurate measurement, Versatile |

| Actuated Valve |

Automated control |

Industrial automation |

Remote control, High precision |

| Motorized Valve |

Electric motor |

Water supply systems |

Automation, Energy-efficient |

Key Features and Benefits of Each Valve Type for Enhanced Efficiency

When selecting electric valve types for efficient control, it's essential to understand the key features and benefits of each. One commonly used valve is the electric ball valve, known for its quick operation and minimal pressure drop, making it ideal for on/off applications. According to a report by Research and Markets, the global electric valve market is projected to reach $14.3 billion by 2026, driven by the demand for automation in industries such as oil and gas, water treatment, and manufacturing.

Another popular choice is the electric globe valve, which provides excellent throttling capabilities due to its design, making it suitable for flow regulation. This valve type is known for its robust construction and ease of maintenance, contributing to lower operational costs in the long run. A study by Grand View Research highlights that the increasing need for efficient fluid control systems across various sectors is propelling the adoption of electric valves.

Tips: When choosing an electric valve, consider the specific requirements of your application, such as pressure, temperature range, and the type of fluid involved. Additionally, assess the compatibility of the valve with your existing control systems to ensure optimal performance. Regular maintenance and testing can further enhance the efficiency of electric valves and extend their lifespan.

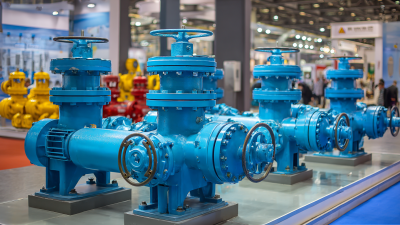

Comparative Analysis of Electric Valve Performance and Application

When evaluating electric valves, it is essential to understand how different types perform in various applications. The performance of electric valves can be influenced by factors such as response time, flow rate, and pressure rating. For example, globe valves are renowned for their ability to provide precise control over flow rates, making them ideal for applications requiring fine adjustments. Conversely, ball valves offer quick shut-off capabilities, which are particularly beneficial in systems that demand rapid operation.

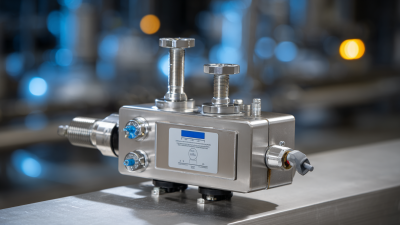

In addition to performance characteristics, the application context of electric valves plays a crucial role in their selection. For instance, the use of electric actuators in corrosive environments may lean towards materials like stainless steel for durability. Additionally, applications in heating, ventilation, and air conditioning (HVAC) systems may prioritize valves with features designed for temperature tolerance and energy efficiency. A comparative analysis of these elements reveals that choosing the right electric valve type not only enhances system efficiency but also contributes to long-term operational reliability.

Top 10 Electric Valve Types Performance Comparison

This chart illustrates the performance efficiency of different types of electric valves based on various parameters.

Future Trends in Electric Valve Technology and Design Innovations

The electric valve market is witnessing significant advancements and innovations, particularly in response to the growing demand for efficient control systems across various industries. According to industry reports, the acidic gas valve market is projected to reach $98.3 million by 2024, with an anticipated increase to $147.09 million by 2032, reflecting a compound annual growth rate of 5.1%. This growth underscores the importance of embracing new technologies and designs in electric valve systems.

Future trends in electric valve technology are moving towards enhanced automation and integration with smart systems, making them more reliable and efficient. Innovations such as IoT connectivity and advanced actuator designs are expected to revolutionize how valves are monitored and controlled, providing real-time data that can significantly improve operational efficiency. These advancements will help industries minimize downtime and optimize performance by swiftly addressing any valve-related issues.

Tips: When selecting electric valves, consider the compatibility of the valve with smart technology to future-proof your systems. Additionally, invest in regular training for staff on the latest valve technologies to maximize their potential returns. Lastly, always stay updated on market trends and technological innovations to ensure your selections remain competitive.

Best Practices for Selecting the Right Electric Valve for Your Needs

When selecting the right electric valve for your needs, it's essential to consider a few key factors to ensure

efficient control in your system. First, evaluate the specific

application for which the valve will be used. Understanding the medium that will flow through the valve—be it water,

gas, or chemicals—can vastly influence your decision. Each medium has different pressure and temperature

requirements that must align with the valve specifications.

Tips: Always check the valve's compatibility with

the flow medium to avoid premature wear and failure. Additionally, consider the valve's size and configuration to

fit seamlessly into your existing system without requiring significant modifications.

Another vital aspect is the type of actuator. Electric valves can be equipped with various actuators, including

on/off,

modulating, or

proportional types. The choice of actuator will depend on

the level of precision needed in control and the response time required for your operations.

Tips: For high-precision applications, choose

a modulating actuator, while on/off actuators are suitable for simpler applications where full open/close functionality suffices.

Remember to assess the power supply requirements as well, ensuring that it can accommodate the selected actuator’s needs.