2026 Top Electric Valve Types You Should Know?

The demand for electric valves continues to rise as industries prioritize automation and energy efficiency. According to a recent report by MarketsandMarkets, the global electric valve market is expected to reach $6.5 billion by 2026, growing at a CAGR of 6.2% from 2021. This trend signifies a shift towards more advanced control systems in various sectors, including oil and gas, water treatment, and manufacturing.

Dr. Emily Carter, a renowned expert in fluid dynamics, emphasizes the importance of understanding different electric valve types. She states, "Choosing the right electric valve is crucial for optimizing system performance." Knowing the various options available can help engineers make informed decisions that enhance operational efficiency.

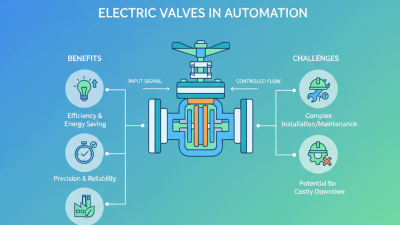

While the advantages of electric valves are clear, challenges remain. Limited knowledge about specific valve functionalities can lead to suboptimal choices. Some users may overlook key factors, like actuator compatibility, causing inefficiencies in their systems. Addressing these issues is essential for maximizing the benefits of electric valves in today's industrial landscape.

Types of Electric Valves: An Overview of 2026 Innovations

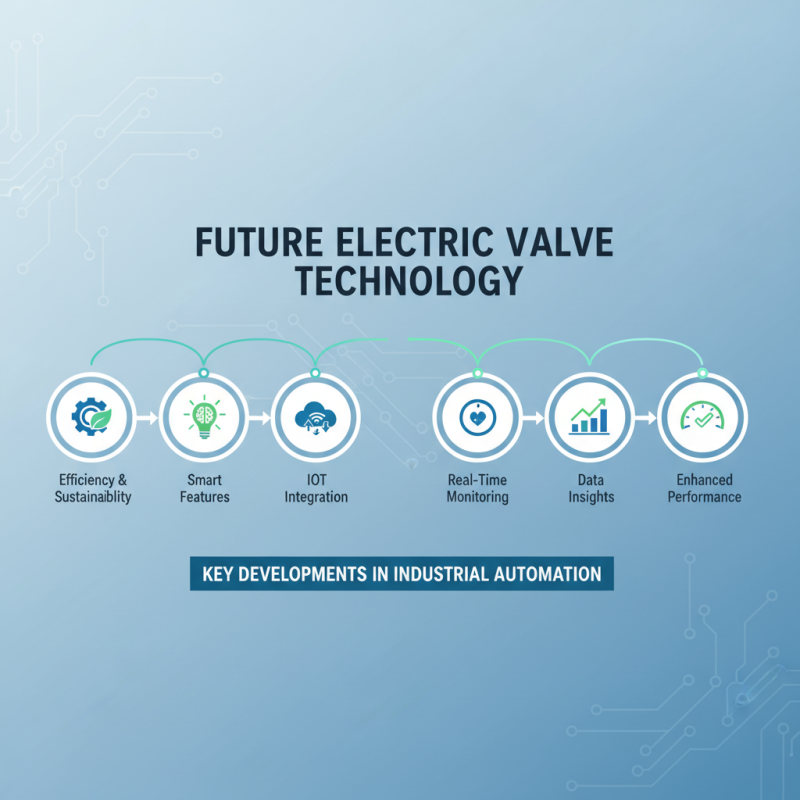

Electric valves are revolutionizing modern automation. In 2026, various types showcase significant innovations. Smart electric valves offer seamless integration with IoT systems. This allows for real-time monitoring and remote operation. Users can enjoy enhanced control and energy efficiency.

Electromagnetic valves are becoming popular for their reliability. They use electromagnetism to manage flow. These valves are compact and suitable for tight spaces. However, they may generate heat and noise. On the other hand, motor-operated valves provide precise control over larger systems. They require more space but deliver strength.

Despite the advancements, challenges remain. Many users struggle with installation complexities and maintenance issues. Some electric valves may not perform well under extreme conditions. This highlights the need for ongoing research and development. The future of electric valves looks promising, yet we must address these imperfections.

2026 Electric Valve Types Overview

Key Features and Benefits of Different Electric Valve Types

Electric valves come in various types, each designed for specific applications. One popular type is the solenoid valve. These valves operate using electromagnetic coils. They offer fast action and are widely used in automation. Their compact design is another advantage, making them ideal for tight spaces. However, they can be sensitive to temperature and pressure. This aspect sometimes leads to performance issues in extreme conditions.

Another common type is the motorized valve. These valves utilize an electric motor for precise control. They provide excellent response times and reliability. This makes them suitable for managing flow in complex systems. However, they can be larger and pricier compared to solenoid valves. Their power consumption can also be a concern. Users should weigh the pros and cons when choosing the right valve for their needs.

Lastly, there are pressure relief valves. These play a crucial role in safety mechanisms. They help prevent system overpressure and potential disasters. While they are vital, ensuring proper maintenance is essential. Neglected valves can lead to malfunction, creating dangerous situations. Balancing efficiency and safety in electric valve selection is key to successful operations.

Applications of Electric Valves Across Various Industries

Electric valves play a critical role in many industries today. Their applications are diverse, spanning oil and gas, water treatment, and manufacturing. In the packaging sector, for instance, electric valves enhance efficiency by controlling fluid flow precisely. According to data from the International Society of Automation, the market for electric valves is expected to reach USD 4.5 billion by 2026, reflecting a growing reliance on automation.

The water treatment industry significantly benefits from electric valves. These devices help regulate water flow and pressure, ensuring that treatment processes run efficiently. A report from Global Market Insights indicates that the demand for electric valves in the water sector will grow at a CAGR of over 5% through 2028. However, organizations should be cautious. Sometimes, improper installation leads to performance issues, such as leaks or system failures.

In manufacturing, electric valves improve control over production processes. They reduce manual labor and enhance safety protocols. Recent studies indicate that industries adopting electric valves have seen productivity increases of nearly 30%. Yet, companies must assess their existing infrastructure before implementation. Transitioning to electric valves without proper planning can cause disruptions. Balancing innovation and operational stability is crucial for any industry adapting to new technologies.

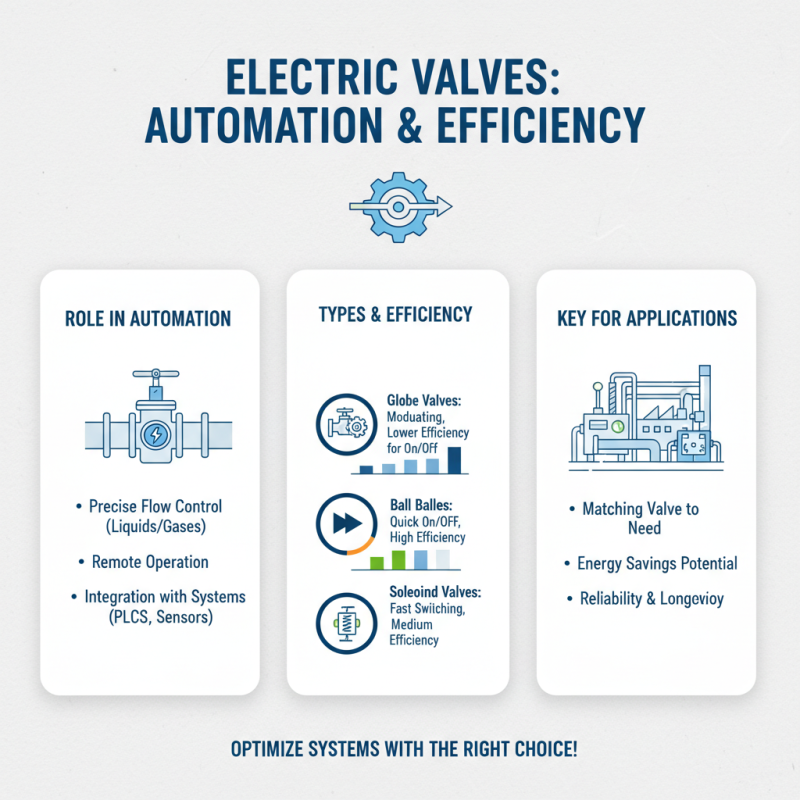

Comparative Analysis of Electric Valve Performance and Efficiency

Electric valves play a vital role in modern automation. They offer precise control over the flow of liquids or gases. However, not all electric valves perform the same. Different types demonstrate varied efficiency levels. Understanding these differences is key for effective applications.

In a comparative analysis, some valves stand out for their rapid response times. Others may have longer actuation periods, impacting overall system efficiency. For example, a ball valve might provide quicker opening and closing than a diaphragm valve. This difference can significantly affect process timing.

Additionally, power consumption varies widely. Some designs require more energy to operate, which can affect long-term costs. It's essential to consider both performance and energy efficiency during selection. Note that maintaining these valves can be challenging. Regular wear impacts reliability. This can lead to unexpected downtime, so reflection on maintenance practices is crucial.