2026 Top Gas Valve Types to Consider for Your Next Project?

In the world of gas valve technology, selecting the right type is crucial for any project. Industry expert John Smith, a leading engineer at Gas Control Solutions, emphasizes, “Choosing the right gas valve can make or break your system's efficiency.” His words highlight the significant role gas valves play in ensuring safety and performance.

Gas valves vary widely in design and function. Each type has specific applications, influenced by factors like pressure and flow rate. Understanding the nuances can be challenging. Many project managers overlook valve specifications, leading to costly errors. A simple oversight can disrupt operations and compromise safety.

Consideration of gas valve types is essential. Each project presents unique demands. A wrong choice can result in inefficiencies. Striking the right balance is fundamental for any gas application. As the industry evolves, staying informed about advancements keeps projects running smoothly.

Overview of Gas Valve Types Available in 2026

In 2026, various gas valve types are set to dominate the market. The industry has seen significant innovation, particularly in safety and efficiency. According to the latest reports, smart gas valves are gaining traction. They enable remote monitoring and control, enhancing safety measures significantly. With the rise of IoT technology, these valves can provide real-time data to operators.

Another type to consider is the ultra-low emissions valve. These valves reduce harmful gas emissions by up to 80%. This is crucial in meeting stricter environmental regulations. As industries shift towards sustainability, gas valves must adapt. Traditional valves are often criticized for inefficiency. They can lead to safety hazards if not monitored properly.

Moreover, pressure-regulating valves continue to play a vital role. They ensure stable gas flow, protecting equipment and enhancing performance. Despite their importance, many businesses overlook their maintenance. Neglecting regular checks can lead to significant operational issues. As gas systems become more complex, the need for reliable components is greater than ever. Choosing the right valve is not just a technical decision; it impacts overall safety and efficiency.

Key Features to Consider When Choosing a Gas Valve

When choosing a gas valve for your next project, consider several critical features. One of the most important is the type of valve. The market offers various types, each suited for different applications. According to a report by the Gas Appliance Manufacturers Association, safety is a prime concern. Ensuring the valve has safety features such as automatic shut-off can prevent accidents and leaks.

Flow capacity is another key factor. It affects how much gas can move through the valve at a given time. Proper sizing is crucial. A poorly sized valve may lead to inefficiencies or even system failures. Data from the American Gas Association shows that improper flow rates can reduce system performance by up to 30%.

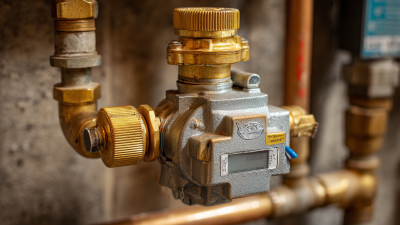

Materials matter too. Valves made from durable materials can withstand high pressures and corrosive environments. Stainless steel and brass are common choices, but each comes with its pros and cons. A valve’s rating affects its longevity and effectiveness. Assessing these features will aid in making an informed decision for your gas-related projects.

2026 Top Gas Valve Types to Consider for Your Next Project

| Valve Type |

Key Features |

Common Applications |

Material |

Pressure Rating (psi) |

| Ball Valve |

Quick shut-off; low pressure drop |

Residential, commercial heating |

Brass, Stainless Steel |

150 - 6000 |

| Gate Valve |

Minimal flow restriction; durable |

Main lines, pipelines |

Cast Iron, PVC |

150 - 2000 |

| Globe Valve |

Excellent throttling control; high resistance |

Water treatment, chemical processes |

Stainless Steel, Bronze |

150 - 3000 |

| Check Valve |

Prevents backflow; automatic operation |

Water supply, wastewater systems |

PVC, Cast Iron |

150 - 2500 |

| Solenoid Valve |

Electrically operated; fast response |

Automated systems, irrigation |

Brass, Plastic |

30 - 150 |

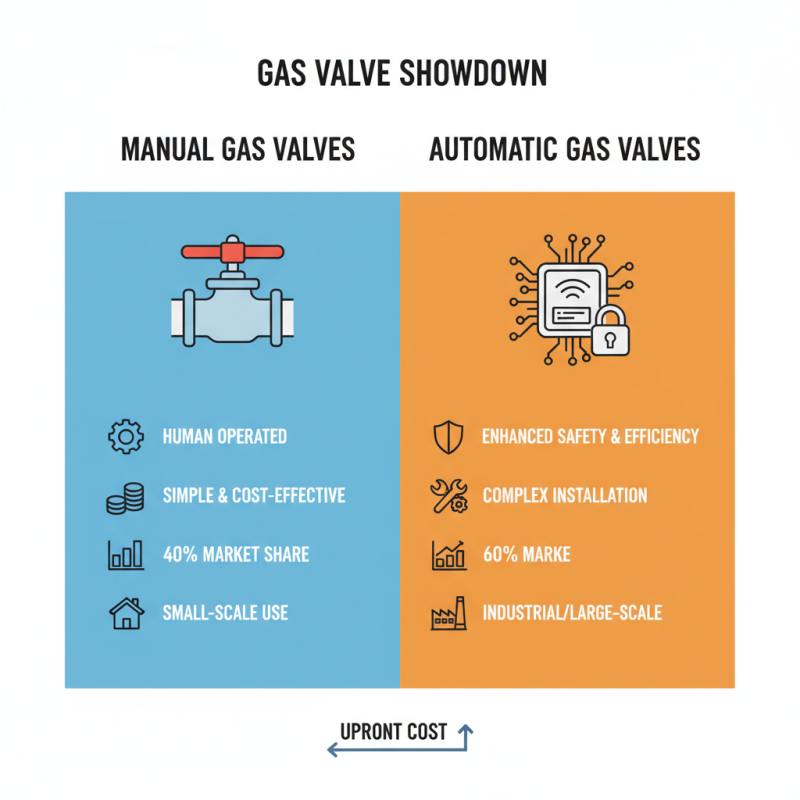

Comparative Analysis of Manual and Automatic Gas Valves

When it comes to gas valves, the debate between manual and automatic options continues. Manual gas valves require human intervention to operate. They are simple and cost-effective. Reports reveal that they make up around 40% of the market, appealing especially to small-scale applications. In contrast, automatic gas valves account for about 60%. They enhance safety and efficiency. However, their installation can be complicated and may require more upfront investment.

Tips: Consider your project's scale. For smaller setups, manual valves might suffice. Always assess operational ease and maintenance requirements too.

Automatic valves offer features like remote operation and integration with smart systems. This can lead to significant energy savings. Yet, not all automatic systems are created equal. Some may lack robust fail-safes. Users should beware of this.

Tips: Evaluate your operational environment. Harsh conditions can impact valve performance. Research options that suit these challenges well. Balancing safety and cost is key. You might face choices that seem lesser or more complicated than expected. Keep safety as your priority.

Applications and Use Cases for Different Gas Valve Types

When selecting gas valves for a project, understanding their applications is essential. Different types serve varied functions. For instance, ball valves are popular for their quick operation. They are ideal for on-off control in gas systems. Their compact design is beneficial in tight spaces.

Another type is the globe valve. Its design allows for precise flow regulation. This is crucial in applications where temperature and pressure need to be controlled. However, they can be less efficient than ball valves in certain situations. Often, the choice comes down to balancing control and efficiency in a process.

Safety is also a significant concern. Safety shut-off valves automatically close when a problem occurs. They are critical in industrial settings to prevent accidents. Yet, they may require regular maintenance to ensure reliability. Each valve type has its strengths and weaknesses. Understanding these can lead to better decisions in your project.

Future Trends in Gas Valve Technology and Innovations

The future of gas valve technology is shaping up to be more efficient and eco-friendly. Recent reports indicate that the global gas valve market is projected to grow significantly, with an expected CAGR of 5.4% from 2021 to 2026. This growth reflects a strong demand for more innovative solutions, particularly in residential and industrial applications.

One emerging trend is the integration of IoT technology in gas valves. Manufacturers are now focusing on smart valves that can be monitored remotely. These devices offer real-time data on flow rates and pressure, allowing for better management of gas usage. According to a recent study by the Gas Technology Institute, 70% of users who adopted smart valves reported improved operational efficiency. However, there are concerns regarding cybersecurity. With increased connectivity comes the risk of hacking, a challenge that must be addressed moving forward.

Another crucial aspect is energy efficiency. The push for sustainability is prompting the development of valves that minimize gas leakage. Innovations in materials, such as polymers and advanced alloys, are being used to improve durability and performance. A survey by the American Society of Mechanical Engineers found that 63% of engineers believe that using advanced materials can reduce failure rates. Despite these advancements, there remain questions on the overall cost. Balancing initial investment with long-term savings is essential. The industry is in a pivotal position, needing to innovate while being mindful of budget constraints.