Top Industrial Water Valves for Efficient Water Management Solutions

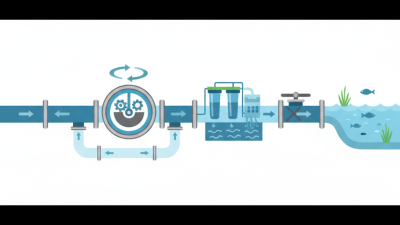

In the realm of industrial operations, the management of water resources is paramount for ensuring both efficiency and sustainability. Industrial water valves play a crucial role in this process, serving as the gatekeepers that regulate the flow and direction of water used in various industrial applications. Given the increasing emphasis on sustainability and the need for efficient water management solutions, selecting the right water valves is essential for optimizing productivity and reducing operational costs.

As industries face regulatory pressures and environmental concerns, the demand for reliable and high-performance industrial water valves continues to grow. These valves not only control water flow but also help mitigate wastage, ensuring that water is used judiciously. From manufacturing facilities to power plants, the integration of advanced valve technologies can lead to significant improvements in water management strategies, promoting both operational efficiency and environmental responsibility.

This article explores the top industrial water valves that stand out for their reliability and efficiency, providing insights into their functionalities and applications. By examining the latest advancements in valve technology and their benefits, we aim to equip industry professionals with the knowledge needed to make informed decisions that align with their water management objectives.

Overview of Industrial Water Valves in Water Management

Industrial water valves play a crucial role in effective water management systems, ensuring the seamless control and distribution of water in various applications. These valves are designed to handle significant pressure variations and are made from durable materials, which makes them essential for industries such as manufacturing, agriculture, and food processing. With a range of types available—such as gate, globe, and ball valves—each serves distinct functions that enhance water flow regulation and prevent leakage.

When selecting industrial water valves, it is vital to consider factors like the flow characteristics, required pressure ratings, and the specific medium being handled. Proper maintenance is equally important to ensure optimal performance. Regularly inspecting for wear and tear, lubricating movable parts, and replacing old components can significantly extend the life of these valves.

Tips: Always choose valves that are compatible with the type of water or fluid in your system. It is also advisable to work with a professional when installing or replacing valves to ensure proper configuration and avoid potential operational issues. Implementing a proactive maintenance schedule can minimize unexpected failures and downtime, ensuring smooth water management.

Top Industrial Water Valves for Efficient Water Management Solutions

| Valve Type |

Material |

Size Range (Inches) |

Max Pressure (psi) |

Application Area |

| Ball Valve |

Stainless Steel |

0.5 - 12 |

150 |

Water Supply |

| Gate Valve |

Ductile Iron |

2 - 36 |

200 |

Industrial Pipelines |

| Globe Valve |

Brass |

0.5 - 10 |

100 |

Flow Regulation |

| Check Valve |

PVC |

1 - 8 |

150 |

Backflow Prevention |

| Pressure Relief Valve |

Stainless Steel |

0.5 - 4 |

300 |

Safety Applications |

Key Features of Efficient Water Management Valves

When selecting industrial water valves for efficient water management solutions, certain key features significantly enhance their functionality and effectiveness. First, durability is crucial. Valves should be constructed from high-quality materials that can withstand harsh environmental conditions, such as extreme temperatures and corrosive substances. This not only prolongs the lifespan of the valve but also reduces maintenance costs and downtime, ensuring continuous operation in critical systems.

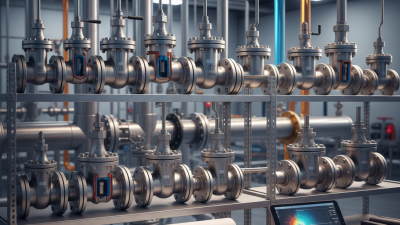

Another important feature is the ease of operation. Valves equipped with user-friendly controls and automation capabilities allow for responsive adjustments, improving overall system efficiency. Smart technology integration, such as remote monitoring and diagnostics, enables operators to track performance in real-time, providing the ability to swiftly address any issues that may arise. Additionally, features like leak detection and flow regulation further contribute to water conservation efforts, preventing waste and ensuring optimal distribution throughout the system.

Finally, compatibility with various piping systems is essential. Valves that offer versatile connection options can easily integrate into existing infrastructures, making them ideal for retrofitting or expanding water management systems. This adaptability not only enhances operational efficiency but also facilitates scalable solutions that grow alongside industrial needs. By focusing on these key features, industries can implement robust water management strategies that lead to sustainability and cost savings.

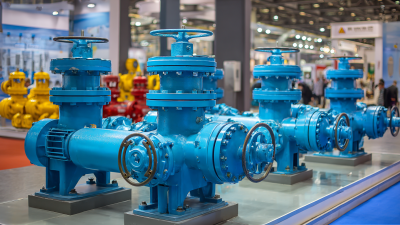

Types of Industrial Water Valves and Their Applications

Industrial water valves play a critical role in managing water systems across various sectors. There are several types of industrial water valves, each designed to meet specific operational needs. Gate valves, commonly used for on-and-off service, provide minimal flow resistance when fully opened, making them ideal for regulating large volumes of water. They are particularly effective in wastewater treatment plants and irrigation systems, where full flow control is essential.

Another essential type is the globe valve, which excels in throttling flow and is frequently utilized in applications requiring precise flow regulation. Their design allows for a higher degree of control, which is particularly important in chemical processing and cooling systems where maintaining specific flow rates can impact overall efficiency and safety. Additionally, ball valves, known for their quick operation, are favored in applications requiring rapid shutoff capabilities, such as in fire suppression systems and water distribution networks. Each valve type plays a unique role in the infrastructure, ensuring efficient water management and supporting the various processes dependent on reliable water supply.

Top Industrial Water Valves Types and Their Applications

Factors Influencing the Selection of Water Valves

When selecting industrial water valves for efficient water management, several critical factors must be considered to ensure optimal performance and sustainability. One of the primary considerations is the type of application for which the valve will be used. For example, water treatment facilities require valves that can handle high pressures and varying flow rates without compromising efficiency. According to a report by the International Water Association, improper valve selection can result in energy losses of up to 30%, highlighting the importance of choosing the right valve type for specific industrial applications.

Material compatibility is another significant factor impacting valve selection. Different industrial environments expose valves to various chemicals, temperatures, and pressures, necessitating a careful assessment of material durability. A study by the American Society of Mechanical Engineers indicates that using the appropriate materials can enhance the lifespan of valves, reducing maintenance costs by up to 40%. Additionally, valve design, such as whether to use a globe, ball, or butterfly valve, can influence flow characteristics and maintenance needs, further emphasizing the importance of a tailored approach based on operational requirements.

Moreover, regulatory compliance and environmental considerations play crucial roles in the decision-making process. Many industries are subject to stringent environmental regulations that mandate the use of low-leakage valves to minimize water loss and reduce environmental impact. The Global Water Intelligence report estimates that adopting more efficient valve technologies could save approximately 15% of total water resources in industrial sectors, reinforcing the necessity for strategically selected water valves that align with both corporate sustainability goals and compliance standards.

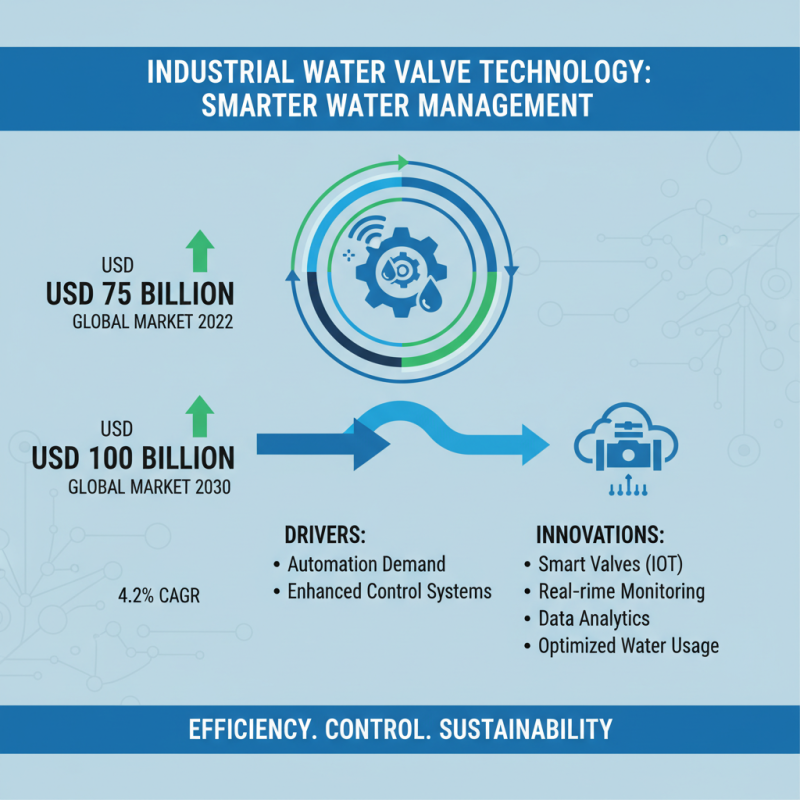

Future Trends in Industrial Water Valve Technology

Recent advancements in industrial water valve technology are paving the way for more efficient water management solutions. The global industrial valves market, valued at approximately USD 75 billion in 2022, is projected to reach USD 100 billion by 2030, reflecting a compound annual growth rate (CAGR) of around 4.2%. This growth is largely driven by the increasing demand for automation and enhanced control systems across various industries. Innovations such as smart valves equipped with IoT capabilities are transforming traditional water management practices, enabling real-time monitoring and data analytics to optimize water usage.

Moreover, sustainability trends are shaping the development of water valves. According to a report from the International Water Association, industries are under pressure to reduce their water footprint, with 70% of manufacturers indicating that they are actively seeking technologies that contribute to water conservation efforts. The latest valve designs now often incorporate advanced materials that are not only more durable but also resistant to corrosion and scaling. This shift not only extends the lifespan of the valves but also minimizes maintenance costs while ensuring reliable operation. As industries adopt these cutting-edge solutions, the focus remains on enhancing efficiency and sustainability in water usage, which is crucial in combating global water scarcity challenges.