Top 7 Pinch Valves for Slurry: Best Options for Optimal Performance in 2023

In the ever-evolving landscape of industrial fluid handling, pinch valves for slurry have emerged as a critical component for achieving optimal performance in various applications. As highlighted by industry expert Dr. Emily Roberts, a leading authority on fluid dynamics, "The efficiency of slurry handling can significantly improve with the right choice of pinch valves, ensuring minimal wear and tear while maximizing flow control." This insight underscores the importance of selecting the best pinch valves specifically designed for slurry applications.

In the ever-evolving landscape of industrial fluid handling, pinch valves for slurry have emerged as a critical component for achieving optimal performance in various applications. As highlighted by industry expert Dr. Emily Roberts, a leading authority on fluid dynamics, "The efficiency of slurry handling can significantly improve with the right choice of pinch valves, ensuring minimal wear and tear while maximizing flow control." This insight underscores the importance of selecting the best pinch valves specifically designed for slurry applications.

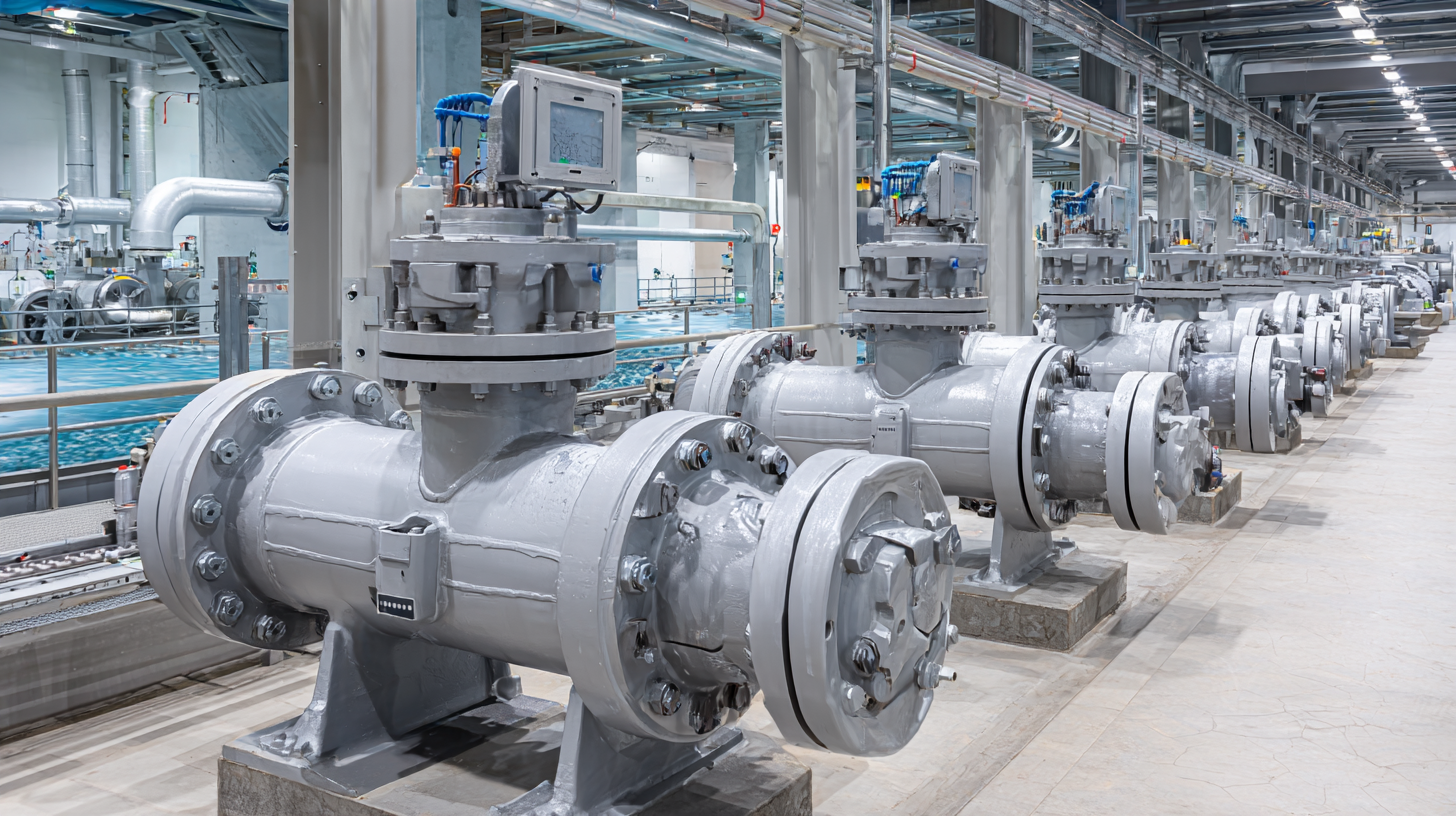

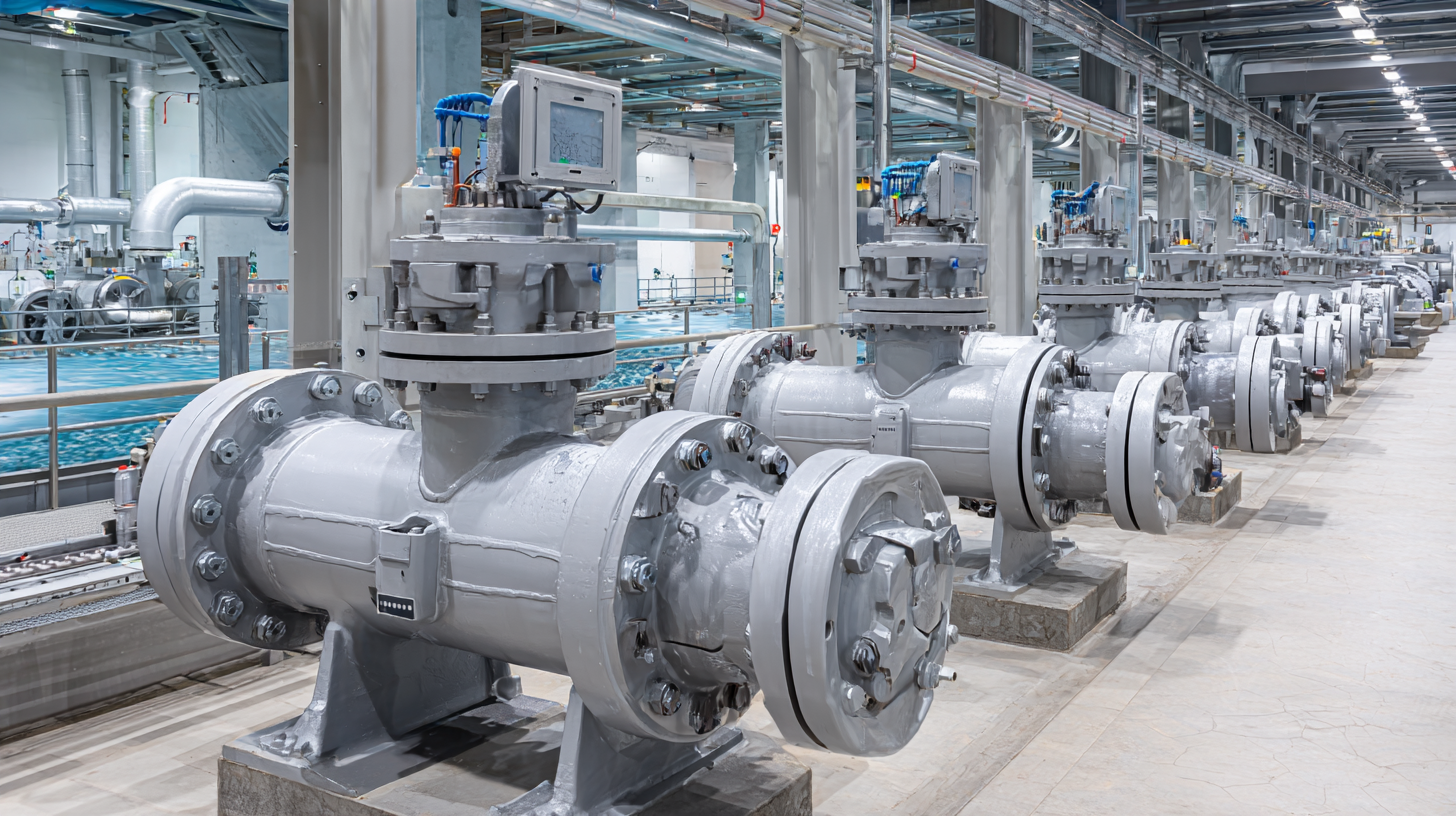

As we delve into the top 7 pinch valves for slurry available in 2023, we will explore their unique features, advantages, and the factors that contribute to their effectiveness in managing abrasive and viscous materials. Slurry transport is not only foundational in sectors like mining and wastewater treatment but also increasingly pivotal in more specialized industries. Therefore, understanding the options available on the market and their performance capabilities is essential for engineers and project managers aiming to enhance operational efficiency and reduce maintenance costs.

In this guide, we will present comprehensive reviews and expert tips on choosing the right pinch valves for slurry, providing practical advice to help you make informed decisions that align with your specific application needs. Whether you're looking to upgrade your existing systems or investing in new technology, the right pinch valves can lead to significant improvements in performance and reliability.

Top Benefits of Using Pinch Valves in Slurry Applications for 2023

Pinch valves have become increasingly popular in slurry applications due to their unique design and functionality. These valves are particularly beneficial for handling abrasive and corrosive materials, as they provide a simple yet effective means of controlling flow without the risk of clogging.

In 2023, the industrial valve market is witnessing a significant growth trajectory, with pinch valves playing a crucial role in this expansion. According to recent industry reports, the global industrial valve market is projected to grow at a considerable rate, reflecting the ongoing demand for efficient fluid handling solutions.

One of the key advantages of pinch valves is their ability to maintain a tight seal when closed, preventing leakage and ensuring minimal product loss. Additionally, they can accommodate a wide range of slurry consistencies, making them ideal for various applications across industries. The ease of maintenance further enhances their appeal, as replacing the rubber sleeve can often be done swiftly, minimizing downtime.

Tips: When selecting a pinch valve for slurry applications, consider factors such as the material compatibility with the medium and the operating pressure. Additionally, ensure proper installation to achieve optimal performance and longevity. Regular inspection and maintenance of pinch valves can greatly extend their service life and reliability in demanding environments.

Key Performance Metrics for Slurry Pinch Valves: Efficiency and Durability Analysis

When selecting a pinch valve for slurry applications, two critical performance metrics to consider are efficiency and durability. Efficiency in slurry pinch valves is essential for minimizing flow resistance and ensuring smooth operation during processes that involve viscous and particulate-laden fluids. High-efficiency valves contribute to lower energy consumption and reduction in operational costs, making them a preferred choice in industrial settings. A well-designed pinch valve can accommodate varying flow rates while maintaining the integrity of the slurry, thus optimizing the overall performance of the system.

Durability is another vital factor, particularly in the challenging environments often associated with slurry transport. Pinch valves must withstand abrasive materials and high wear conditions, necessitating robust materials and construction methods. The longevity of a valve directly impacts maintenance costs and downtime, which are critical considerations for industries relying heavily on continuous operations. Thus, evaluating the durability alongside efficiency not only helps in choosing the right valve but also ensures long-term reliability and effectiveness in managing slurry flow challenges in industrial applications.

Comparison of Different Pinch Valve Materials: Which is Best for Slurry Handling?

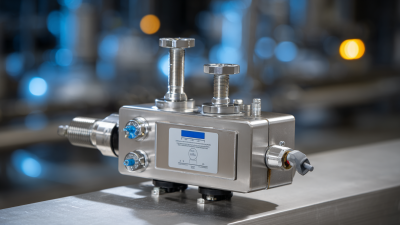

When selecting pinch valves for slurry handling, understanding the material composition is crucial for optimal performance. Common materials used in pinch valves include rubber, plastic, and metal, each offering unique benefits and limitations. According to a recent industry report by MarketsandMarkets, rubber-only pinch valves are less prone to wear in abrasive conditions, making them a favorite in mining and wastewater applications. However, they can be vulnerable to chemical degradation, which makes the selection of the right material essential for specific slurry types.

For operations involving highly abrasive slurries, metal pinch valves, often crafted from stainless steel, offer superior durability. However, the initial investment is higher compared to rubber or plastic options. Research from the Hydraulic Institute indicates that while metal valves extend operational life, they require more significant maintenance, which could impact overall efficiency. On the other hand, thermoplastic pinch valves showcase excellent resistance to corrosive materials and provide a weight advantage, but users may find compromises on pressure ratings.

**Tips:** Always conduct a thorough analysis of the slurry's composition before selecting the valve material. Consider the working environment and potential wear factors. Regular maintenance and inspections can significantly extend the life of your pinch valves, ensuring consistent performance and reliability in your operations.

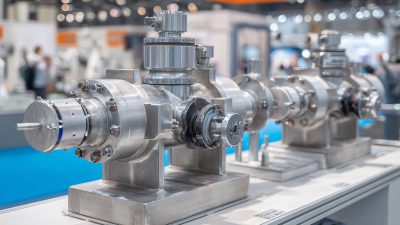

Industry Trends in Slurry Management: Innovations in Pinch Valve Technology for 2025

In the ever-evolving landscape of slurry management, the advancements in pinch valve technology are poised to redefine operational efficiencies and performance outcomes by 2025. With the growing demand for reliable flow control solutions that can handle abrasive and viscous materials, manufacturers are focusing on creating pinch valves that ensure minimal downtime and maintenance. Innovations in materials, such as the use of advanced elastomers and reinforced composites, are enhancing the durability of these valves, making them more resilient to harsh conditions often found in slurry applications.

Additionally, the integration of smart technologies into pinch valves is set to revolutionize the industry. IoT-enabled pinch valves will provide real-time monitoring and data analytics, allowing operators to optimize flow rates and detect issues before they escalate into costly failures. This proactive approach to slurry management not only boosts operational efficiency but also contributes to sustainability by minimizing waste and energy consumption. As we look ahead to 2025, the trend towards automation and data-driven decision-making will likely lead to significant improvements in how industries manage slurry transport, positioning pinch valves as a crucial component in achieving these objectives.

Understanding Maintenance Requirements for Optimal Pinch Valve Performance in Slurry Systems

Maintaining pinch valves in slurry systems is crucial for ensuring optimal performance and longevity. Regular inspections should be a part of your maintenance routine to identify any wear or damage to the valve components. Focus particularly on the tubing and seals, as these parts are susceptible to abrasion and can significantly affect the efficiency of the valve. Establishing a routine for cleaning the valves can also help prevent buildup of materials that might obstruct flow.

Tips: Always keep a log of maintenance activities, noting any changes in performance or issues encountered. This log can help you identify patterns over time and anticipate potential failures before they occur. Additionally, consider implementing a schedule for replacing wear parts, which can reduce downtime and enhance overall system reliability.

Regularly calibrating your pinch valve controls is another essential maintenance task that can prevent operational inconsistencies. Proper calibration ensures precise control of the flow rate, which is especially important when handling slurry composed of various particle sizes. Keeping your pinch valves correctly adjusted not only prolongs their lifespan but also enhances the efficiency of the entire system.

In the ever-evolving landscape of industrial fluid handling, pinch valves for slurry have emerged as a critical component for achieving optimal performance in various applications. As highlighted by industry expert Dr. Emily Roberts, a leading authority on fluid dynamics, "The efficiency of slurry handling can significantly improve with the right choice of pinch valves, ensuring minimal wear and tear while maximizing flow control." This insight underscores the importance of selecting the best pinch valves specifically designed for slurry applications.

In the ever-evolving landscape of industrial fluid handling, pinch valves for slurry have emerged as a critical component for achieving optimal performance in various applications. As highlighted by industry expert Dr. Emily Roberts, a leading authority on fluid dynamics, "The efficiency of slurry handling can significantly improve with the right choice of pinch valves, ensuring minimal wear and tear while maximizing flow control." This insight underscores the importance of selecting the best pinch valves specifically designed for slurry applications.