The Top 5 Tech Valves Revolutionizing Industrial Automation in 2023

In 2023, the landscape of industrial automation is witnessing a transformative shift driven by innovations in technology, particularly in the realm of tech valves. According to a report by Mordor Intelligence, the global market for industrial valves is projected to reach over USD 100 billion by 2028, growing at a CAGR of 5.2%. This growth is substantially fueled by the surge in automation technologies and the increasing demand for efficient and reliable control systems across various industries.

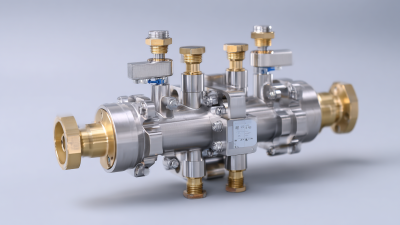

Tech valves, characterized by their advanced functionalities and adaptability, are pivotal to the seamless operation of automated systems. They enable enhanced fluid control, promote safety, and reduce operational costs, making them indispensable in sectors such as manufacturing, oil and gas, and water management. With the integration of IoT and AI, these valves are not only equipped to perform traditional roles but also to provide real-time analytics and predictive maintenance capabilities. As industries continue to prioritize efficiency and sustainability, the relevance of tech valves in industrial automation is more critical than ever, paving the way for reduced downtime and optimized performance.

The Role of Tech Valves in Industrial Automation Advancements

In 2023, tech valves have emerged as critical components driving advancements in industrial automation. These innovative devices not only enhance operational efficiency but also play a fundamental role in achieving higher levels of safety and precision in various processes. According to a recent industry report by MarketsandMarkets, the global market for smart valves is projected to grow at an impressive CAGR of 14.5% from 2022 to 2027, highlighting the increasing demand for automated solutions in manufacturing and supply chain environments.

The integration of tech valves in industrial systems facilitates real-time monitoring and data analysis, enabling businesses to make informed decisions and optimize performance. By utilizing IoT technology, these valves can communicate seamlessly with other automation components, fostering a more interconnected and responsive operation. The same report notes that organizations implementing smart valves have reported a reduction in operational costs by up to 20%, significantly improving their bottom lines while enhancing compliance with safety regulations. As industries continue to evolve, the role of tech valves in streamlining processes and mitigating risks cannot be overstated, marking a pivotal shift towards fully automated operations.

Key Technologies Driving the Evolution of Valves in Industry

In 2023, the industrial sector is witnessing a transformative shift with the introduction of advanced valve technologies, which are becoming pivotal in enhancing automation processes. Key technologies such as smart sensors, predictive analytics, and artificial intelligence are driving the evolution of valves in various applications. These innovations enable valves to operate more efficiently, provide real-time data for monitoring, and facilitate remote operation, significantly reducing the need for manual intervention and increasing efficiency in production lines.

Moreover, the integration of IoT (Internet of Things) capabilities into valve systems allows for seamless connectivity and interoperability with other automated systems. This integration fosters a more cohesive industrial environment where data flows freely between devices, enabling proactive maintenance and improved decision-making. As industries continue to strive for higher productivity and reduced operational costs, the adoption of these cutting-edge valve technologies is likely to set the foundation for future advancements in industrial automation, leading to smarter, safer, and more energy-efficient operations.

Top 5 Tech Valves Reshaping Operational Efficiency in 2023

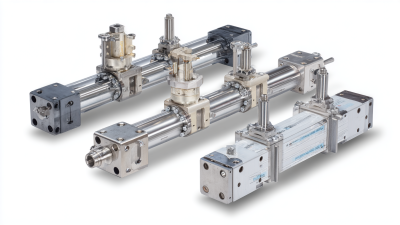

In 2023, the evolution of tech valves has significantly reshaped operational efficiency across various industries. These advanced valves are designed to integrate seamlessly with automation systems, enhancing workflow precision and minimizing downtime. Their ability to provide real-time data and feedback allows organizations to streamline processes, ensuring that resources are utilized optimally. As industries continue to adopt these technologies, the necessity for robust and intelligent valve systems becomes clearer.

Tips for maximizing the benefits of tech valves include regularly monitoring their performance through data analytics. Implementing predictive maintenance strategies can preemptively address potential issues, ensuring that operations remain uninterrupted. Furthermore, training your personnel in the latest automation technologies can facilitate smoother integration and demonstrate the full capabilities of these systems.

By adopting tech valves that offer better control and efficiency, companies can dramatically reduce waste and operating costs. It's also essential to foster a culture of continuous improvement, encouraging teams to innovate and tweak existing systems for enhanced performance. As a result, organizations not only meet operational goals but also position themselves competitively in the ever-evolving industrial landscape.

The Top 5 Tech Valves Revolutionizing Industrial Automation in 2023

This bar chart illustrates the efficiency improvements brought by the top five technology valves in the industrial automation sector for the year 2023. Each valve contributes significantly to operational processes by enhancing productivity and reducing downtime.

Impact of Smart Valves on Process Control and Automation

In 2023, smart valves have emerged as pivotal components in the landscape of industrial automation, significantly enhancing process control. According to a recent report by ResearchAndMarkets, the global smart valve market is projected to reach $5.6 billion by 2025, reflecting a compound annual growth rate (CAGR) of 13.2%. These advancements in valve technology enable real-time data analytics, which empower organizations to make informed decisions, optimize performance, and reduce operational costs.

The integration of smart valves into automated systems not only boosts efficiency but also enhances safety protocols. By utilizing Internet of Things (IoT) connectivity, these valves facilitate remote monitoring and control, allowing for rapid responses to potential issues. A study from McKinsey indicates that companies adopting advanced automation technologies, including smart valves, can achieve up to a 30% reduction in operational costs, while also minimizing downtime through predictive maintenance.

Tips: To maximize the benefits of smart valve technology, it's crucial to focus on training your staff to effectively interpret data analytics. Additionally, regularly scheduled maintenance of these smart systems can prevent unexpected failures and prolong the lifespan of your equipment. Embracing the data-driven approach will not only improve process control but also foster a culture of continuous improvement within your organization.

Future Trends: The Next Generation of Valves in Industrial Settings

The industrial automation sector is undergoing a significant transformation, with the next generation of valves at the forefront of this evolution. As of 2023, the global industrial valve market is projected to grow at a compound annual growth rate (CAGR) of 4.8%, reaching approximately $92 billion by 2027, according to a recent industry report. This growth is largely driven by advancements in technology that enhance efficiency, precision, and reliability in automated processes.

Among the key trends shaping the future of valves in industrial settings is the increased integration of IoT (Internet of Things) technologies. Smart valves equipped with sensors and connectivity features are enabling real-time monitoring and data analysis, which facilitate proactive maintenance and reduce downtime. These innovations allow for more efficient energy management and operational optimization, boosting overall productivity. Additionally, features like predictive analytics are gaining traction, providing operators with valuable insights into valve performance and enabling timely interventions.

Moreover, sustainability is becoming a major focus in valve development. With stricter environmental regulations and a push toward greener operations, the new generation of valves is designed to minimize leaks and energy losses. Reports indicate that implementing advanced sealing technologies can reduce emissions by up to 30%, aligning with the industry’s growing commitment to sustainable practices. This trend not only enhances environmental performance but also fosters cost savings, making it a vital consideration for industries aiming for both innovation and sustainability in their automation strategies.