Top 10 Water Valves You Need to Know: Best Types for Home and Industry

In the realm of plumbing and fluid management, water valves play a pivotal role in the efficient control and distribution of water, both in domestic and industrial settings. According to a report by the Global Water Management Market, the water valve industry is projected to reach a market value of $156 billion by 2025, highlighting the increasing demand for reliable and efficient water control systems. With various types of water valves available, understanding which ones best serve specific applications is crucial for ensuring optimal performance and sustainability in water usage.

Water valves not only regulate flow and pressure but also play a significant part in preventing leaks and ensuring safety in water distribution systems. The International Plumbing Code emphasizes the necessity of using high-quality water valves to maintain the integrity of plumbing systems, which directly correlates to reduced water waste and enhanced energy efficiency. Selecting the appropriate valve type is essential for any homeowner or industry professional looking to invest in long-lasting, efficient solutions to manage their water supply effectively. In this article, we will explore the top 10 water valves you need to know, covering essential aspects that cater to both household needs and industrial applications.

Types of Water Valves: An Overview of Common Types and Their Uses

Water valves play a crucial role in both residential and industrial settings, ensuring the efficient flow and control of water. Understanding the various types of water valves is essential for anyone involved in plumbing or water management. According to a market research report by MarketsandMarkets, the global valve market is projected to grow from USD 85.1 billion in 2020 to USD 116.3 billion by 2025, driven by the increasing need for effective water management and infrastructure upgrades.

Among the most common types of water valves are gate valves, globe valves, ball valves, and check valves. Gate valves are widely used for on/off control, offering minimal resistance when fully open. Meanwhile, globe valves excel in regulating flow, making them ideal for applications requiring precise control. Ball valves, known for their durability and quick operation, are often utilized in both residential plumbing and industrial systems. Check valves, on the other hand, prevent backflow, protecting systems from potential damage. According to a study by Technavio, the demand for ball valves in residential applications is forecasted to see a rise of 5% annually, reflecting their growing popularity for home use.

Top 10 Water Valves You Need to Know: Best Types for Home and Industry

| Valve Type |

Common Uses |

Advantages |

Limitations |

| Gate Valve |

Water supply systems |

Low pressure drop, good for on/off control |

Not suitable for throttling |

| Ball Valve |

Irrigation and plumbing |

Quick operation, excellent sealing |

Can be more expensive |

| Globe Valve |

Flow regulation applications |

Good throttling ability |

Higher pressure drop |

| Check Valve |

Preventing backflow |

Automatic operation |

Limited control over flow direction |

| Butterfly Valve |

Water distribution systems |

Lightweight, compact design |

Not as effective for throttling |

| Pressure Relief Valve |

Protection of systems |

Prevents overpressure |

Can lead to system leaks |

| Solenoid Valve |

Automated water control |

Fast response, remote control |

Requires electrical supply |

| Swing Check Valve |

Pumping systems |

Effective for preventing backflow |

May not seal well under low pressure |

| Cage Valve |

Wastewater systems |

Handles high flow rates |

Requires more space for operation |

| Y-Valve |

Diverging flow paths |

Versatile flow control |

Can be complex to install |

The Importance of Water Valves in Residential and Industrial Settings

Water valves play a critical role in both residential and industrial settings, serving as key components in managing water flow and temperature. In homes, various types of water valves, such as shut-off valves, pressure reducing valves, and thermostatic mixing valves, contribute to safety and efficiency in plumbing systems. They help in maintaining optimal water temperature and pressure, preventing leaks and water wastage, and ensuring comfort in everyday activities such as showering and cooking.

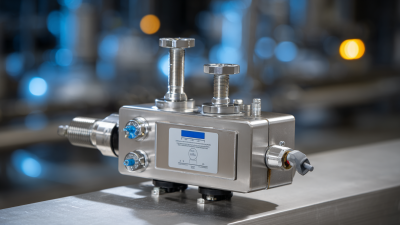

In industrial scenarios, the importance of water valves is magnified due to the complexity and scale of water systems. Industries rely on advanced valve technologies to control water usage tightly, manage system pressure, and handle different fluid properties efficiently. For instance, thermostatic mixing valves are witnessing growth in the market, expected to reach over USD 2 billion by 2035. This surge reflects the increasing demand for precision in water temperature control, emphasizing how critical these components are for both residential satisfaction and industrial productivity.

Key Features to Consider When Choosing Water Valves

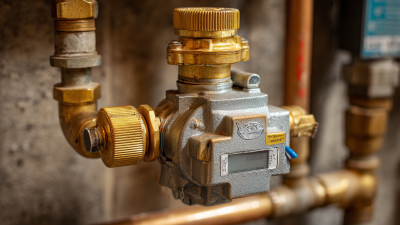

When selecting water valves for home or industrial use, several key features should be taken into account to ensure optimal performance and reliability. Firstly, the valve size is crucial; it should match the piping system to prevent leaks and ensure proper flow rates. Additionally, the material of the valve plays a significant role in its longevity and effectiveness. Common materials include brass, stainless steel, and PVC, each suitable for different environments and pressures.

Another essential consideration is the type of valve mechanism, such as gate, globe, or ball valves, as each operates differently and serves distinct purposes. For instance, ball valves are ideal for quick shut-off applications due to their quarter-turn action, while globe valves are better for regulating flow. Furthermore, factors like pressure rating and temperature tolerance should align with the specific requirements of your system to prevent failures. Lastly, ease of maintenance and installation should also be evaluated, as this can significantly impact long-term operational costs and convenience in both home and industrial settings.

Maintenance Tips for Ensuring Optimal Performance of Water Valves

When it comes to maintaining water valves, ensuring optimal performance is crucial for both home and industrial applications. Regular maintenance not only extends the lifespan of these valves but also enhances system efficiency. According to a report from the American Water Works Association, improper valve maintenance can lead to a 30% increase in operational costs due to leaks and inefficiencies. Therefore, regular checks for leaks and wear, as well as lubricating moving parts, are essential practices.

Furthermore, valve inspection protocols suggest examining seals and mechanisms at least once a year. A study by the International Journal of Water Resources Management indicates that implementing a proactive maintenance schedule can reduce emergency repair costs by up to 40%. In addition, educating staff on how to recognize early signs of wear can preempt bigger issues down the road. Regular flushing of valves can also prevent sediment build-up, ensuring smooth operation and compliance with industry standards. Prioritizing these maintenance tips can lead to significant savings and improved functionality in both residential and industrial water systems.

Comparative Analysis of Top 10 Water Valves for Home and Industrial Applications

When selecting water valves for both home and industrial applications, understanding the comparative strengths and weaknesses of various types is essential. For residential use, gate valves and ball valves are often preferred due to their straightforward mechanisms and effective flow control. Gate valves provide minimal pressure loss and are ideal for situations where the valve remains either fully opened or closed. Conversely, ball valves offer rapid operation and durability, making them suitable for quick shut-off in high-pressure systems.

In industrial settings, however, the demands shift towards valves that can withstand harsher conditions. Butterfly valves and check valves come into play, as they are designed to handle significant pressure and temperature variations. Butterfly valves are compact and efficient, enabling large volumes of water to be regulated while minimizing space requirements. Check valves, on the other hand, prevent backflow, ensuring system integrity. A thorough comparative analysis of these valve types showcases the importance of selecting the right valve for specific applications, aligning efficiency, durability, and performance with the operational needs of both residential and industrial environments.