Why Is the Waste Valve Essential for Efficient Waste Management?

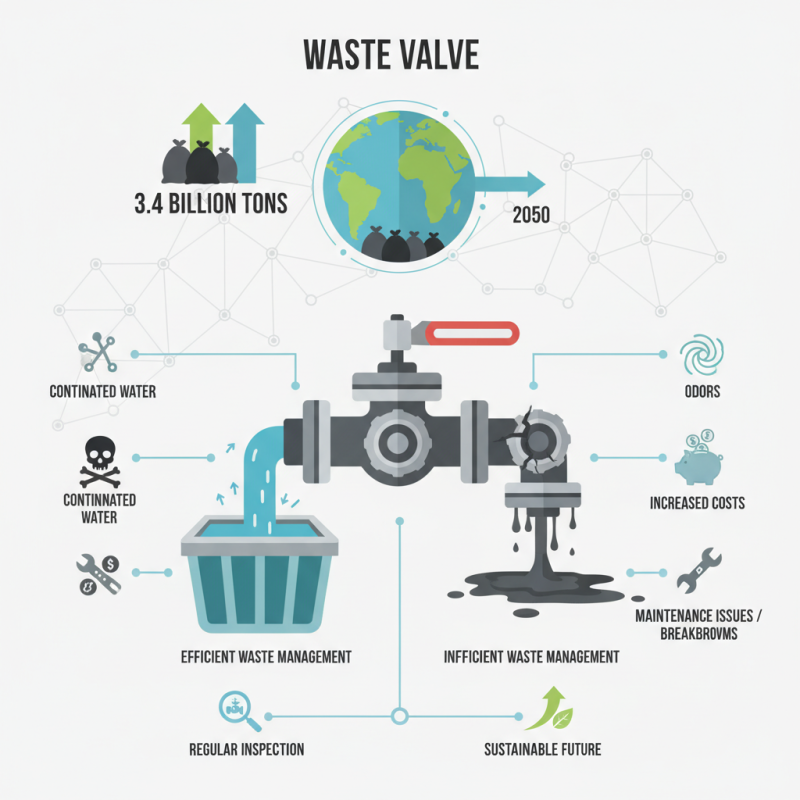

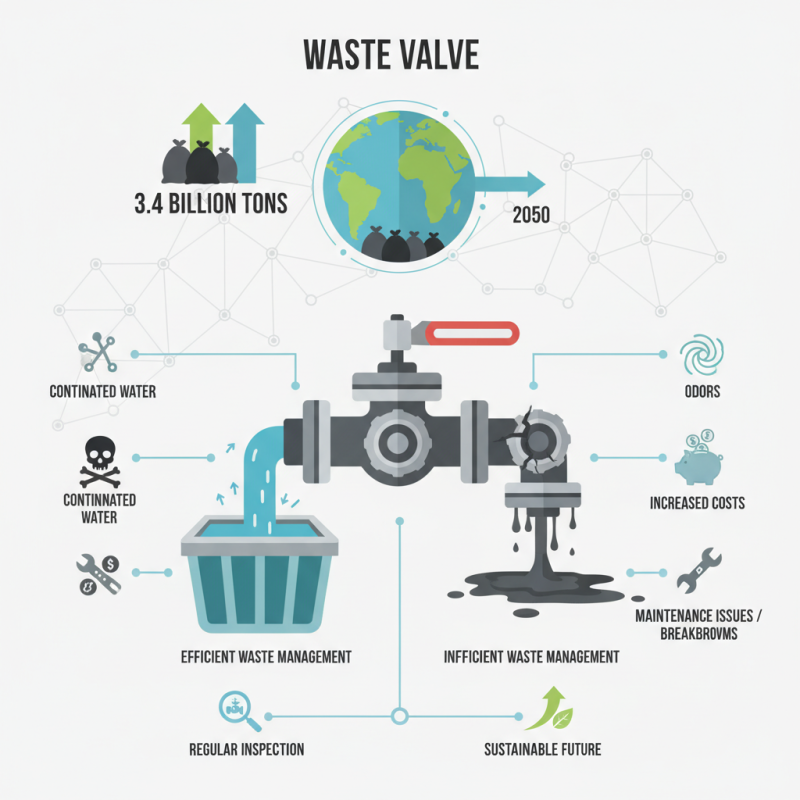

The waste valve plays a crucial role in efficient waste management systems. According to the World Bank, global waste is expected to reach 3.4 billion tons by 2050. This immense quantity highlights the need for effective systems to handle waste efficiently. A properly functioning waste valve allows for controlled waste discharge, minimizing overflow and leaks.

Without a reliable waste valve, facilities may face significant challenges. Contaminated water, noxious odors, and increased operational costs can result from poor waste management. Recent industry reports indicate that improper management can escalate maintenance costs by 20%. Each failure can reflect broader inefficiencies in a facility, requiring urgent review.

Moreover, waste valves require regular inspection and maintenance, often overlooked. This can lead to unexpected breakdowns, resulting in service disruption. As we confront rising waste levels, addressing the role of the waste valve is essential for sustainable waste management. It urges facilities to reflect on their current practices and consider improvements.

What Is a Waste Valve and Its Role in Waste Management?

A waste valve is a crucial device in waste management systems. It controls the flow of waste fluids and helps prevent overflow. Proper functioning of this valve ensures that waste is efficiently managed, promoting a cleaner environment. When waste is not correctly channeled, it can lead to contamination and health risks.

One essential function of the waste valve is to allow regulated discharge. This prevents sudden surges that can overwhelm treatment facilities. A malfunctioning waste valve can cause significant delays in waste disposal. These delays might lead to unpleasant odors and safety hazards.

**Tip:** Regular maintenance of waste valves is vital. Check for wear and tear, as this can affect performance. Keeping valves clean enhances their efficiency.

Another critical aspect is emergency shut-off capability. In case of a malfunction, it limits waste spillage. However, operators should ensure they understand the valve’s mechanism. A lack of knowledge can result in improper handling during crises.

**Tip:** Always read the manual. Familiarity with the device can aid in decision-making when issues arise. Investing time in training staff pays off in the long run.

Waste valves play a significant role in a functional waste management system, yet they require ongoing attention. Their maintenance can sometimes be overlooked, leading to costly repairs. Recognizing the importance of these devices is essential for promoting sustainability.

The Mechanism Behind Waste Valve Operation and Flow Control

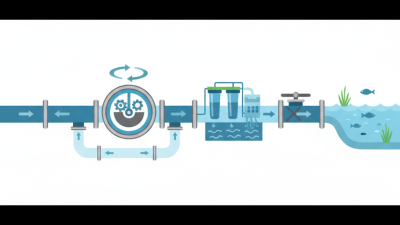

The waste valve plays a pivotal role in waste management systems. It governs the flow and disposal of waste materials. This valve opens or closes to regulate how waste exits a system. When it works correctly, it ensures that waste is efficiently removed. Yet, when it fails, problems can arise. Overflow can cause environmental issues and health risks.

Understanding how a waste valve operates is crucial. It utilizes pressure and gravity to manage waste flow. When activated, the valve allows waste to exit smoothly. However, blockages can disrupt this process, leading to delays and backups. Regular inspections are necessary to catch these issues early. Many overlook this simple yet effective mechanism.

A properly functioning waste valve enhances system efficiency. Yet, occasional leaks or slow responses can compromise this. Users should stay vigilant and maintain their systems. Observing changes can provide insights into potential failures. The balance of operation and maintenance is fragile yet vital. These factors ultimately dictate the success of waste management efforts.

Benefits of Implementing Waste Valves in Various Waste Systems

The implementation of waste valves in waste systems brings several notable benefits. One major advantage is the improvement of liquid waste management. These valves allow for the controlled release of waste materials. This can significantly reduce the risk of leaks and spills, which are common in traditional systems. By ensuring a more efficient waste flow, waste valves contribute to cleaner environments.

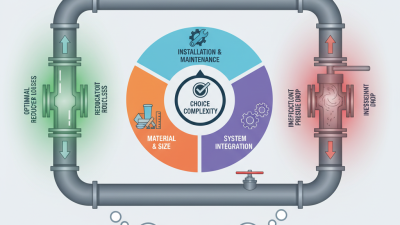

In addition, waste valves enhance operational efficiency. They minimize the need for frequent maintenance by preventing blockages and buildup. However, the installation process can be complex and may require specialized knowledge. Monitoring systems are essential to ensure they function optimally. Some organizations might overlook this aspect, leading to potential issues down the line.

Another important benefit is the reduction of environmental impact. With better waste control, harmful substances are less likely to enter natural ecosystems. Yet, there is still a risk of human error during valve operation. Training personnel becomes crucial to mitigate this risk. Waste valves can offer a solution to common waste management problems but require careful management to maximize their effectiveness.

Why Is the Waste Valve Essential for Efficient Waste Management? - Benefits of Implementing Waste Valves in Various Waste Systems

| Waste System Type |

Benefits of Waste Valve |

Efficiency Improvement (%) |

Maintenance Reduction (%) |

| Municipal Waste |

Reduces overflow and enhances flow control |

30 |

25 |

| Industrial Waste |

Improves safety and compliance with regulations |

40 |

20 |

| Hazardous Waste |

Prevents leaks and environmental contamination |

50 |

15 |

| Wastewater Management |

Enhances treatment efficiency and minimizes sludge |

35 |

30 |

| Recycling Systems |

Increases throughput and material recovery rates |

45 |

22 |

Common Issues Associated with Waste Valves and Their Solutions

Waste valves play a crucial role in waste management systems. However, they are not without issues. One common problem is valve clogging. This can reduce flow rates significantly. According to the Environmental Protection Agency, clogged valves can decrease efficiency by over 30%, leading to increased operational costs. Regular maintenance is essential to avoid this.

Another issue is valve wear and tear. Over time, materials can degrade due to corrosive waste. This deterioration can compromise the entire system. A study from the Waste Management Association indicates that nearly 20% of waste management failures stem from faulty valves. Implementing a preventive maintenance schedule can extend the life of waste valves.

Finally, improper installation can create serious problems. Misalignment may lead to leaks and inefficiencies. A report shows that 15% of waste valve issues arise from installation errors. Training staff in accurate installation techniques can mitigate this risk. Addressing these common issues is vital for effective waste management.

Future Innovations in Waste Valve Technology for Efficient Management

Innovations in waste valve technology are crucial for efficient waste management. These components play a vital role in controlling the flow of waste, ensuring optimal processing and reducing environmental impact. In fact, the latest industry reports suggest that effective waste valve systems can increase operational efficiency by up to 30%. This reduction significantly lowers costs and helps facilities meet stringent regulatory requirements.

Emerging trends show a strong focus on smart waste management solutions. Automation is becoming a popular choice. For example, integrating sensors in waste valves can provide real-time data on waste levels and conditions. Such innovations enable proactive maintenance, reducing downtime and preventing costly failures. However, not all facilities have adopted these technologies. Some still rely on outdated systems, missing out on these benefits.

Moreover, sustainability remains a challenge. While new materials and design approaches are improving valve lifespans, many existing types are still prone to leaks. The industry must address these inefficiencies. As waste generation continues to rise globally, addressing these issues is vital. Research indicates that up to 50% of waste management failures stem from inadequate waste valve technology. This highlights the need for continuous advancements in this area.