What is Wastewater Valves and How Do They Work in Treatment Systems

Wastewater valves play a crucial role in the effective management and treatment of wastewater within various systems. As populations grow and urban areas expand, the need for efficient wastewater treatment becomes increasingly important to protect our environment and public health. In this context, wastewater valves are essential components that control the flow of wastewater through treatment processes, ensuring that water is adequately processed before being released back into the natural water cycle.

Understanding how wastewater valves operate is fundamental to grasping their significance in treatment systems. These valves are designed to regulate the movement of water, allowing for precise control of flow rates and pressure within pipelines. By doing so, they facilitate efficient treatment operations and minimize the risk of system overloads or contamination events. This introduction aims to explore the functionality of wastewater valves and their integral role in maintaining the effectiveness and reliability of wastewater treatment systems, ultimately contributing to sustainable water management practices.

What is Wastewater Valves: Definition and Purpose in Treatment Systems

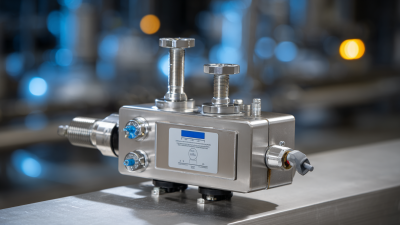

Wastewater valves play a critical role in the efficient operation of treatment systems. Defined as mechanical devices that regulate the flow and pressure of wastewater within infrastructure, these valves ensure that the treatment process functions smoothly and effectively. Their primary purpose is to control the direction of water flow, isolate parts of the system for maintenance, and manage pressures during various operational phases. According to a report from the Water Environment Federation, approximately 75% of wastewater treatment facilities utilize some form of flow control devices, including valves, to maintain optimal performance and safety in the system.

The functionality of wastewater valves is vital in both traditional and advanced treatment systems. They can be actuated manually or automatically, responding to real-time conditions in the wastewater, such as flow rate and pressure variations. For instance, a study by the American Water Works Association notes that improper valve operation can lead to inefficiencies that waste energy and resources. Properly installed and maintained wastewater valves ensure that systems can handle fluctuations in wastewater inflow, which is particularly critical during heavy rainfall events or peak usage times. By integrating intelligent monitoring technologies, facilities can enhance the reliability of these valves, ultimately improving overall treatment outcomes and protecting water quality standards.

Types of Wastewater Valves and Their Specific Applications in Treatment Plants

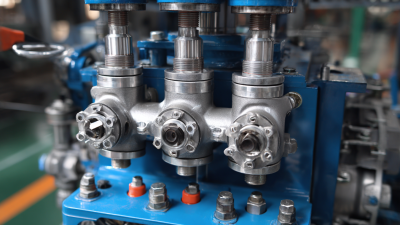

Wastewater treatment systems rely heavily on various types of valves to ensure efficient operation and regulation of fluids. One of the most common types is the gate valve, which is used to start or stop the flow of wastewater. Its simple design allows for a full flow and minimal pressure loss when fully opened, making it suitable for large pipes in treatment plants. However, gate valves should not be used for throttling due to their potential for creating turbulence and wear.

Another important type of valve is the check valve, which prevents backflow in the system. These valves allow wastewater to flow in one direction while automatically closing to stop any reverse flow. This function is critical for protecting pumps and other equipment from damage due to backpressure. In treatment systems, check valves can be found at various points, such as after pumps and on discharge lines. Additionally, ball valves are favored for their ease of operation and reliability, commonly used where quick shut-off capabilities are needed. Each valve type plays a vital role in maintaining the effectiveness and safety of wastewater treatment processes, ensuring that treatment systems run smoothly while minimizing environmental impacts.

Types of Wastewater Valves and Their Applications in Treatment Plants

Mechanisms of Operation: How Wastewater Valves Control Flow and Pressure

Wastewater valves play a crucial role in treatment systems by controlling the flow and pressure of wastewater as it moves through various stages of treatment. These valves can operate as either manual or automated devices, helping maintain optimal conditions in the treatment process. According to industry reports, about 30% of wastewater treatment system failures can be attributed to valve malfunctions, highlighting the importance of maintaining their operational integrity. The mechanisms through which wastewater valves operate are designed to regulate flow and pressure, thereby ensuring efficient treatment and preventing overflows or backflows.

In a typical wastewater treatment setup, valves utilize different mechanisms such as gate, globe, and butterfly designs. Gate valves allow for full flow when opened, while globe valves are used to regulate flow. Butterfly valves are particularly popular in large-scale applications due to their compact design and quick operation. Automation is increasingly implemented in these valves, utilizing sensors and controllers to maintain ideal flow rates and pressure settings, which can lead to up to a 25% increase in system efficiency, as suggested by recent evaluations done in the field.

Tip: Regular inspection and maintenance of wastewater valves can significantly reduce the risk of failures. Implementing a proactive maintenance schedule can identify potential issues before they result in costly downtime, ensuring that your wastewater treatment system remains efficient and compliant with environmental regulations. Another best practice is to use pressure relief valves in your systems, which can act as a safeguard against fluctuations in pressure that may lead to valve damage or system failures.

Importance of Wastewater Valves: Impact on System Efficiency and Environmental Compliance

Wastewater valves play a crucial role in the efficient operation of treatment systems. These valves are designed to control the flow and pressure of wastewater, ensuring that the treatment process runs smoothly. By regulating the amount of wastewater that enters different treatment stages, valves help maintain optimal conditions for microbial activity and chemical reactions, which are vital for effective purification. This regulation not only improves treatment efficiency but also enhances the overall performance of the system.

The importance of wastewater valves extends beyond operational efficiency; they are also essential for environmental compliance. Properly functioning valves prevent leaks, overflows, and spills, which can lead to significant environmental hazards and regulatory fines. By minimizing the risk of contamination, wastewater valves help facilities adhere to environmental standards and protect local ecosystems. Regular maintenance and inspection of these valves are key to ensuring their reliability and efficacy.

**Tips:** Ensure that wastewater valves are regularly inspected and maintained to prevent any potential failures. Consider implementing a scheduled maintenance plan that includes testing for leaks and functionality. Additionally, training staff on the importance of these valves can help promote a culture of compliance and operational efficiency within the facility.

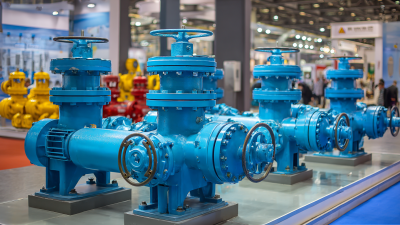

Industry Standards and Maintenance Practices for Wastewater Valves in Treatment Systems

In wastewater treatment systems, valves play a critical role in regulating the flow of water, ensuring efficiency and safety. Industry standards for wastewater valves are typically established by organizations such as the American Water Works Association (AWWA) and the American National Standards Institute (ANSI). These standards dictate specifications for materials, design, and performance to ensure that valves can withstand the corrosive nature of wastewater environments. Compliance with these standards is crucial for maintaining the integrity of treatment systems and ensuring the long-term durability of the infrastructure.

Regular maintenance practices for wastewater valves are essential to prevent failure and to ensure optimal operation. Routine inspections should include checking for leaks, ensuring the correct operation of manual and automatic controls, and cleaning any debris that may obstruct valve function. Maintenance schedules should adhere to the manufacturer's recommendations and relevant industry guidelines, ensuring that all components are periodically tested and replaced as necessary. Implementing effective maintenance practices not only prolongs the life of the valves but also enhances the overall reliability of the wastewater treatment process.

What is Wastewater Valves and How Do They Work in Treatment Systems

| Valve Type |

Function |

Material |

Standard Size |

Maintenance Frequency |

| Gate Valve |

On/Off control |

Cast Iron |

6 inches |

Annually |

| Ball Valve |

Quick shut-off |

PVC |

4 inches |

Semi-Annually |

| Check Valve |

Prevent backflow |

Stainless Steel |

3 inches |

Quarterly |

| Butterfly Valve |

Flow regulation |

Aluminium |

8 inches |

Monthly |

| Air Release Valve |

Release trapped air |

Brass |

2 inches |

Bi-Annually |